Liquid Cold Plate

The liquid cold plate is a kind of efficient heat sink of IGBT, GTO and other powerful elements. It can control the temperature of the power module so that it does not exceed the maximum temperature specified in the standard and specification under the working conditions. The calculation of the maximum permissible temperature is based on the finite element thermal analysis and the analysis of the working conditions of the components and is consistent with the reliability requirements of the products and the requirements of the operating environment. So as to achieve the power module safe, stable and reliable operation and extend the service life of the equipment. High-power dissipated electronic equipment is often used to control the hot spot temperature by forcing the liquid cold plate device of liquid cooling. The water cooling heatsink is made of copper or aluminum with high thermal conductivity. The water circulation system is embedded into the liquid cooling plate, and the electronic components are fixed directly on the water cooling plate. Compared with the air cooled system, the heat capacity of water is four times that of air, so the water cooled system has a good thermal load capacity, and at the same temperature rise and mass flow rate, the heat absorbed by water is four times that of air.

Liquid cooling techniques became the thermal management approach to priority. Kingka Tech can provide all-around liquid cooling solutions and we are providing you with the thermal design, structural design, pipework assembly design of liquid and water cold plates and one-stop supplementary services. Several liquids and water cold plate techniques are available for selection depending on the application scenarios.

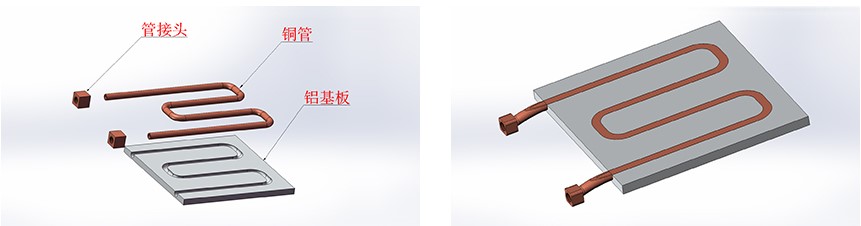

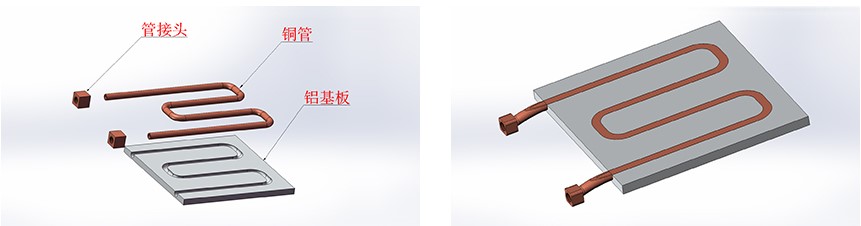

Buried-tube types:

Exposed-tube technique: This technique applies to devices to be installed on one side. Copper tubes are pressed to deform into the grooves within an aluminum plate and then a fly-cut is applied to the surface. This allows the quick removal of heat due to the high thermal conductivity of copper tubes. Meanwhile, the lightweight aluminum can reduce the total weight and keep the cost to a reasonable extent.

Micro-channels + friction welding:

Extrusion techniques are used to form the flow passages of the cold plate directly and the flow passages are connected through by machining any blockage. The assembly is sealed by the friction welding technique with a high production throughput and low cost. This technique is not suitable for applications with higher power density or too many screw holes on the surface since this will create constraints for the flow passages. The main applications include the cooling of power batteries, heating devices, and integrated cooling products such as standard power modules.

Advantages:

Use ICEPAK thermal simulation analysis software to provide customers with leading engineering design and thermal management solutions.

Design and production are integrated to ensure the implementation of heat dissipation solutions and ensure the heat dissipation effect.

Perfect production process and quality inspection system to ensure delivery time and product quality.

Liquid Cold Plate

The liquid cold plate is a kind of efficient heat sink of IGBT, GTO and other powerful elements. It can control the temperature of the power module so that it does not exceed the maximum temperature specified in the standard and specification under the working conditions. The calculation of the maximum permissible temperature is based on the finite element thermal analysis and the analysis of the working conditions of the components and is consistent with the reliability requirements of the products and the requirements of the operating environment. So as to achieve the power module safe, stable and reliable operation and extend the service life of the equipment. High-power dissipated electronic equipment is often used to control the hot spot temperature by forcing the liquid cold plate device of liquid cooling. The water cooling heatsink is made of copper or aluminum with high thermal conductivity. The water circulation system is embedded into the liquid cooling plate, and the electronic components are fixed directly on the water cooling plate. Compared with the air cooled system, the heat capacity of water is four times that of air, so the water cooled system has a good thermal load capacity, and at the same temperature rise and mass flow rate, the heat absorbed by water is four times that of air.

Liquid cooling techniques became the thermal management approach to priority. Kingka Tech can provide all-around liquid cooling solutions and we are providing you with the thermal design, structural design, pipework assembly design of liquid and water cold plates and one-stop supplementary services. Several liquids and water cold plate techniques are available for selection depending on the application scenarios.

Buried-tube types:

Exposed-tube technique: This technique applies to devices to be installed on one side. Copper tubes are pressed to deform into the grooves within an aluminum plate and then a fly-cut is applied to the surface. This allows the quick removal of heat due to the high thermal conductivity of copper tubes. Meanwhile, the lightweight aluminum can reduce the total weight and keep the cost to a reasonable extent.

Micro-channels + friction welding:

Extrusion techniques are used to form the flow passages of the cold plate directly and the flow passages are connected through by machining any blockage. The assembly is sealed by the friction welding technique with a high production throughput and low cost. This technique is not suitable for applications with higher power density or too many screw holes on the surface since this will create constraints for the flow passages. The main applications include the cooling of power batteries, heating devices, and integrated cooling products such as standard power modules.

Advantages:

Use ICEPAK thermal simulation analysis software to provide customers with leading engineering design and thermal management solutions.

Design and production are integrated to ensure the implementation of heat dissipation solutions and ensure the heat dissipation effect.

Perfect production process and quality inspection system to ensure delivery time and product quality.