| Availability: | |

|---|---|

We're a well-established manufacture for aluminium products,having been in this line for 10 years,we're confident we can give our customers complete satisfication.We can provide good quality with reasonable price.We can produce what size and shape of such heat sink you want.Which Aluminium Profiles We could supply.Sufcace Finish:Millfinish, Anodized, Powder coated, Wooden grain.Colors: Silver white, champagne, simulated stainless steel, sand, bronze, black, blue, etc.Mould: Based on your drawing or use our mould free.Technology Supports:Engineering design.Autocad drawing.Aluminium profiles deeplyprocessing:cutting,punching,drilling,milling,dendinand fabricating.

We're a well-established manufacture for aluminium products,having been in this line for 10 years,we're confident we can give our customers complete satisfication.We can provide good quality with reasonable price.We can produce what size and shape of such heat sink you want.Which Aluminium Profiles We could supply.Sufcace Finish:Millfinish, Anodized, Powder coated, Wooden grain.Colors: Silver white, champagne, simulated stainless steel, sand, bronze, black, blue, etc.Mould: Based on your drawing or use our mould free.Technology Supports:Engineering design.Autocad drawing.Aluminium profiles deeplyprocessing:cutting,punching,drilling,milling,dendinand fabricating.

Quality Control

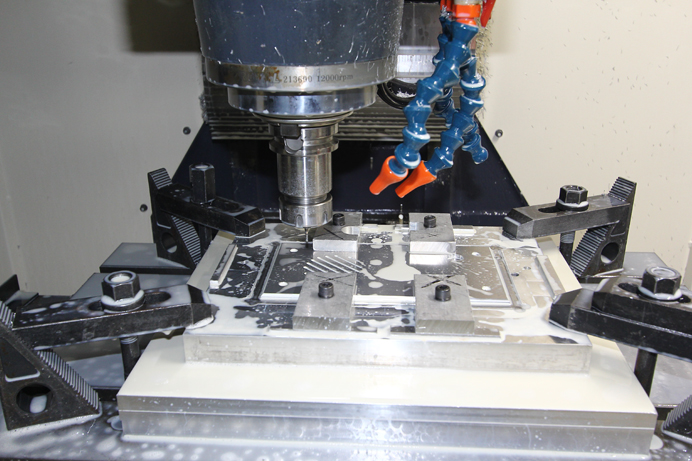

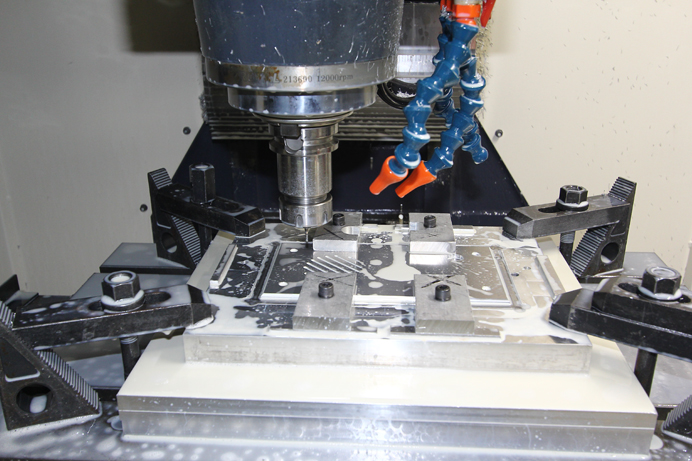

1,Technicians self-check in production

2,Engineer spot check in production

3,QC inspects after mass production finished

4,International sales who were trained the technical know-how spot check before shipping

5,Application expertise.

6,Quality,reliability and long product life.

7,Mature,perfect and excellence,but simple design.

Projector inspecion to check the dimension

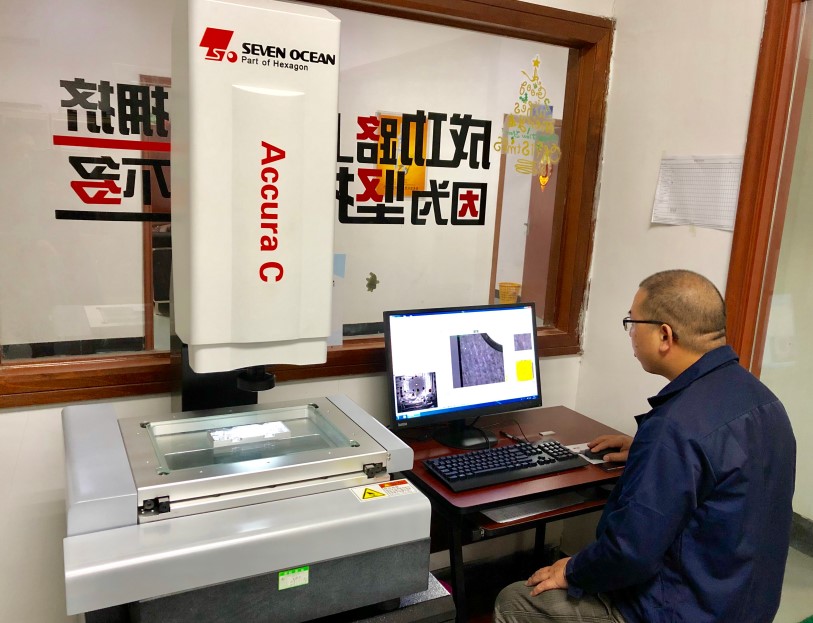

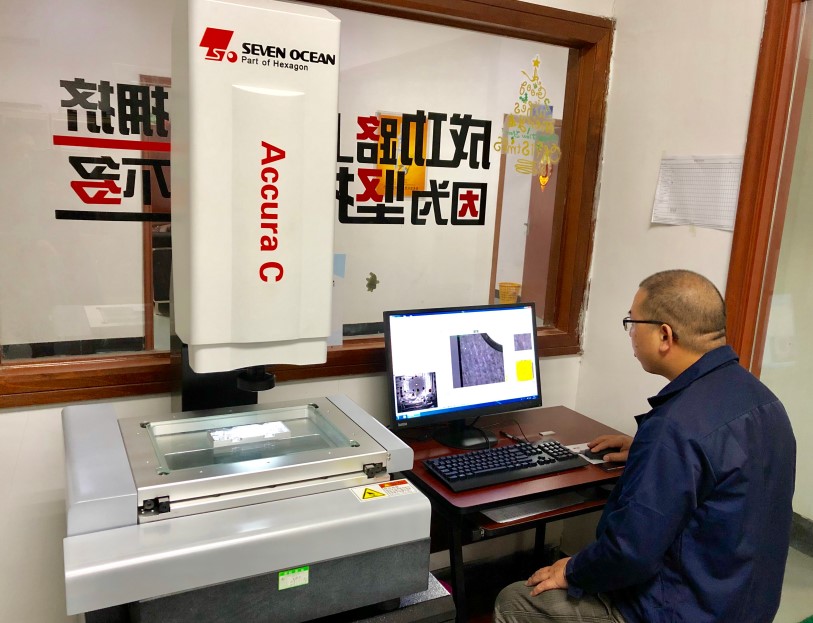

CMM inspection to check the dimensions

Tickness inspection to check the thickness film

Roughness inspection to check the surface roughness

Quality Control

1,Technicians self-check in production

2,Engineer spot check in production

3,QC inspects after mass production finished

4,International sales who were trained the technical know-how spot check before shipping

5,Application expertise.

6,Quality,reliability and long product life.

7,Mature,perfect and excellence,but simple design.

Projector inspecion to check the dimension

CMM inspection to check the dimensions

Tickness inspection to check the thickness film

Roughness inspection to check the surface roughness