| Availability: | |

|---|---|

The custom aluminum top panel is designed for electronic components, utilizing high-quality aluminum alloys (6061 or 6063) to ensure durability and performance. With precise CNC machining, we deliver panels that meet exact specifications and industry standards.

Material: Aluminum 6063 or 6061

Size: 80mm x 320mm x 400mm x 5mm

Surface Treatment: Anodizing and powder coating (available in black and golden finishes)

Packaging: Poly bag and carton, 10kg/carton, suitable for pallet or container shipping

Material Selection: High-grade aluminum plates.

CNC Machining: Advanced techniques including turning, milling, and drilling to achieve precise dimensions.

Surface Treatment: Anodizing and powder coating for enhanced aesthetics and corrosion resistance.

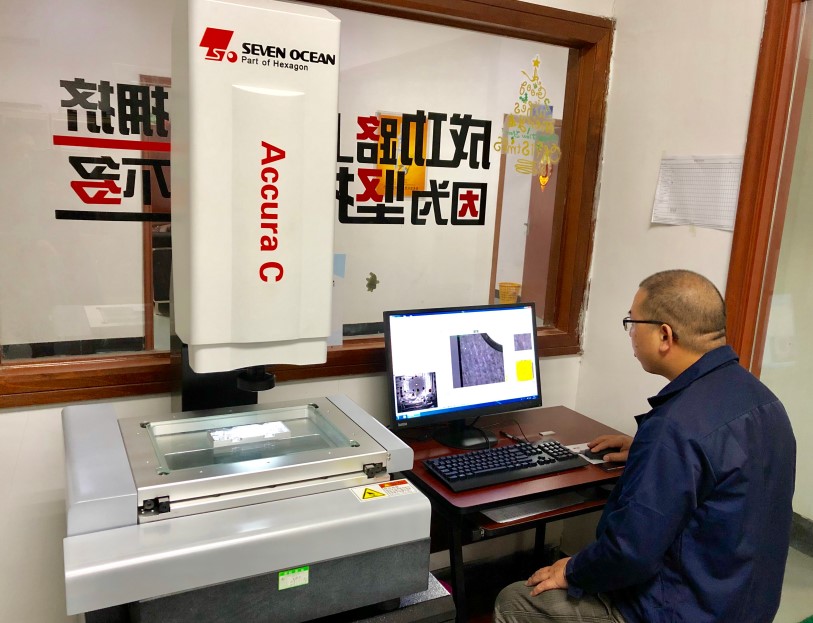

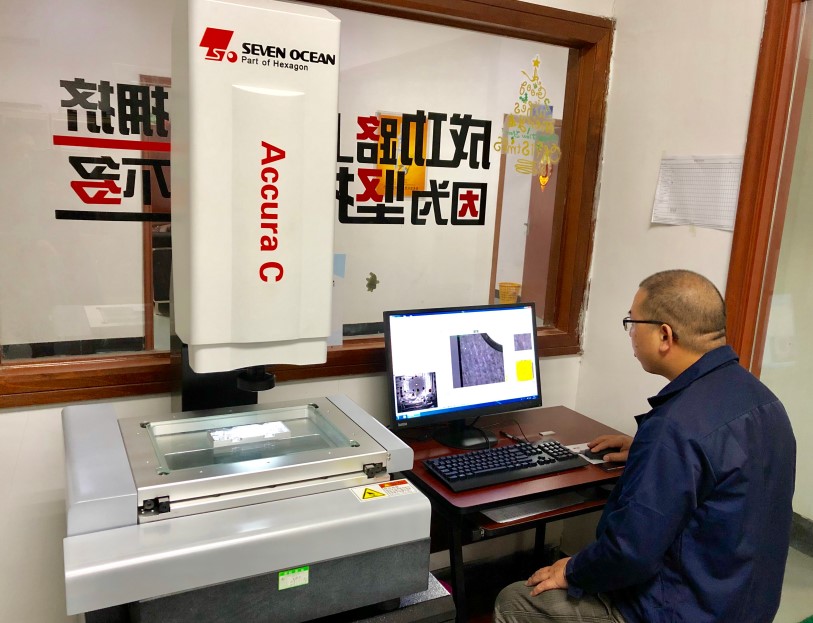

Quality Assurance: Rigorous inspection using CMM, gauges, and roughness testers to ensure product integrity.

Customer Input: Drawings or specifications

Design Proposal and Simulation

Prototype Development and Verification

Customer Validation and Tooling Fabrication

Pre-Series Production Followed by Acceptance Validation

Mass Production

Comprehensive end-to-end custom manufacturing solutions

Experienced engineering team for design refinement and process optimization

Capability to handle low quantity orders with quick delivery

OEM and ODM services with over 15 years of experience

Strong commitment to quality and customer satisfaction

Flexible shipping options via EMS, DHL, UPS, FedEx, or sea/air freight

Payment methods include T/T and other flexible options

Warranty on defective products with clear return policies

CNC Machining Workshop

Produtions Material

Anodizing workshop

Material Cutting line

CNC Machining Toolings

The custom aluminum top panel is designed for electronic components, utilizing high-quality aluminum alloys (6061 or 6063) to ensure durability and performance. With precise CNC machining, we deliver panels that meet exact specifications and industry standards.

Material: Aluminum 6063 or 6061

Size: 80mm x 320mm x 400mm x 5mm

Surface Treatment: Anodizing and powder coating (available in black and golden finishes)

Packaging: Poly bag and carton, 10kg/carton, suitable for pallet or container shipping

Material Selection: High-grade aluminum plates.

CNC Machining: Advanced techniques including turning, milling, and drilling to achieve precise dimensions.

Surface Treatment: Anodizing and powder coating for enhanced aesthetics and corrosion resistance.

Quality Assurance: Rigorous inspection using CMM, gauges, and roughness testers to ensure product integrity.

Customer Input: Drawings or specifications

Design Proposal and Simulation

Prototype Development and Verification

Customer Validation and Tooling Fabrication

Pre-Series Production Followed by Acceptance Validation

Mass Production

Comprehensive end-to-end custom manufacturing solutions

Experienced engineering team for design refinement and process optimization

Capability to handle low quantity orders with quick delivery

OEM and ODM services with over 15 years of experience

Strong commitment to quality and customer satisfaction

Flexible shipping options via EMS, DHL, UPS, FedEx, or sea/air freight

Payment methods include T/T and other flexible options

Warranty on defective products with clear return policies

CNC Machining Workshop

Produtions Material

Anodizing workshop

Material Cutting line

CNC Machining Toolings

Quality Control

1,Technicians self-check in production

2,Engineer spot check in production

3,QC inspects after mass production finished

4,International sales who were trained the technical know-how spot check before shipping

5,Application expertise.

6,Quality,reliability and long product life.

7,Mature,perfect and excellence,but simple design.

Projector inspecion to check the dimension

CMM inspection to check the dimensions

Tickness inspection to check the thickness film

Roughness inspection to check the surface roughness

Quality Control

1,Technicians self-check in production

2,Engineer spot check in production

3,QC inspects after mass production finished

4,International sales who were trained the technical know-how spot check before shipping

5,Application expertise.

6,Quality,reliability and long product life.

7,Mature,perfect and excellence,but simple design.

Projector inspecion to check the dimension

CMM inspection to check the dimensions

Tickness inspection to check the thickness film

Roughness inspection to check the surface roughness