| Availability: | |

|---|---|

Product Name: Marine Low Friction Ring and Cable Aluminum ThimbleMaterial: High-strength aluminum alloy, available in various materials including stainless steel, copper, brass, and steel.Sizes Available: From 10mm x 7mm to 28mm x 14mm, catering to diverse application needs.Surface Treatment: Options include black anodizing and hard anodizing for enhanced durability and corrosion resistance.Production Process:

Extrusion

CNC Machining

Surface Treatment

Packaging: Inner packaging with white paper, followed by carton packing for secure delivery.

Low Friction Design: Engineered to minimize friction, making it ideal for high-load applications such as backstays, control lines, and reefing systems.

Durability: Hard anodized finish provides resistance to wear and corrosion, ensuring longevity in harsh marine environments.

Lightweight Construction: Significantly lighter than traditional bearing blocks, improving overall rigging efficiency.

Versatile Applications: Suitable for various uses including sailboat rigging, lashings, and static load scenarios.

Reduced Wear and Tear: The low friction design minimizes the wear on ropes and cables, extending their lifespan and reducing maintenance costs.

Improved Load Distribution: The thimble's design helps distribute loads evenly, preventing point loading and potential failure points.

High Load Capacity: Designed to handle significant loads, ensuring safety during use in demanding marine environments.

Corrosion Resistance: The anodized surface treatment protects against saltwater and environmental factors, making it ideal for marine applications.

Sailing: Perfect for use in rigging systems, including halyards, sheets, and control lines, enhancing sailing performance.

Fishing: Useful in commercial and recreational fishing for securing nets and lines, providing reliable performance under load.

Customized Solutions: We offer OEM and ODM services tailored to your specific requirements, ensuring a perfect fit for your applications.

Expert Engineering Support: Our experienced engineering team utilizes advanced software like AutoCAD and SolidWorks to refine designs for manufacturability and optimize processes.

Quality Assurance: Comprehensive quality control measures including CMM inspections, roughness testing, and hardness testing ensure high standards are met.

Flexible Shipping Options: We provide various shipping methods including EMS, DHL, UPS, and sea freight, with flexible terms like EXW, FCA, FOB, and DDP.

Quick Response Time: Inquiries regarding products or pricing are addressed within 8 hours by our fluent English-speaking staff.

CNC Machining Workshop

Produtions Material

Material Cutting line

CNC Machining Toolings

Product Name: Marine Low Friction Ring and Cable Aluminum ThimbleMaterial: High-strength aluminum alloy, available in various materials including stainless steel, copper, brass, and steel.Sizes Available: From 10mm x 7mm to 28mm x 14mm, catering to diverse application needs.Surface Treatment: Options include black anodizing and hard anodizing for enhanced durability and corrosion resistance.Production Process:

Extrusion

CNC Machining

Surface Treatment

Packaging: Inner packaging with white paper, followed by carton packing for secure delivery.

Low Friction Design: Engineered to minimize friction, making it ideal for high-load applications such as backstays, control lines, and reefing systems.

Durability: Hard anodized finish provides resistance to wear and corrosion, ensuring longevity in harsh marine environments.

Lightweight Construction: Significantly lighter than traditional bearing blocks, improving overall rigging efficiency.

Versatile Applications: Suitable for various uses including sailboat rigging, lashings, and static load scenarios.

Reduced Wear and Tear: The low friction design minimizes the wear on ropes and cables, extending their lifespan and reducing maintenance costs.

Improved Load Distribution: The thimble's design helps distribute loads evenly, preventing point loading and potential failure points.

High Load Capacity: Designed to handle significant loads, ensuring safety during use in demanding marine environments.

Corrosion Resistance: The anodized surface treatment protects against saltwater and environmental factors, making it ideal for marine applications.

Sailing: Perfect for use in rigging systems, including halyards, sheets, and control lines, enhancing sailing performance.

Fishing: Useful in commercial and recreational fishing for securing nets and lines, providing reliable performance under load.

Customized Solutions: We offer OEM and ODM services tailored to your specific requirements, ensuring a perfect fit for your applications.

Expert Engineering Support: Our experienced engineering team utilizes advanced software like AutoCAD and SolidWorks to refine designs for manufacturability and optimize processes.

Quality Assurance: Comprehensive quality control measures including CMM inspections, roughness testing, and hardness testing ensure high standards are met.

Flexible Shipping Options: We provide various shipping methods including EMS, DHL, UPS, and sea freight, with flexible terms like EXW, FCA, FOB, and DDP.

Quick Response Time: Inquiries regarding products or pricing are addressed within 8 hours by our fluent English-speaking staff.

CNC Machining Workshop

Produtions Material

Material Cutting line

CNC Machining Toolings

Quality Control

1,Technicians self-check in production

2,Engineer spot check in production

3,QC inspects after mass production finished

4,International sales who were trained the technical know-how spot check before shipping

5,Application expertise.

6,Quality,reliability and long product life.

7,Mature,perfect and excellence.

Projector inspecion to check the dimension

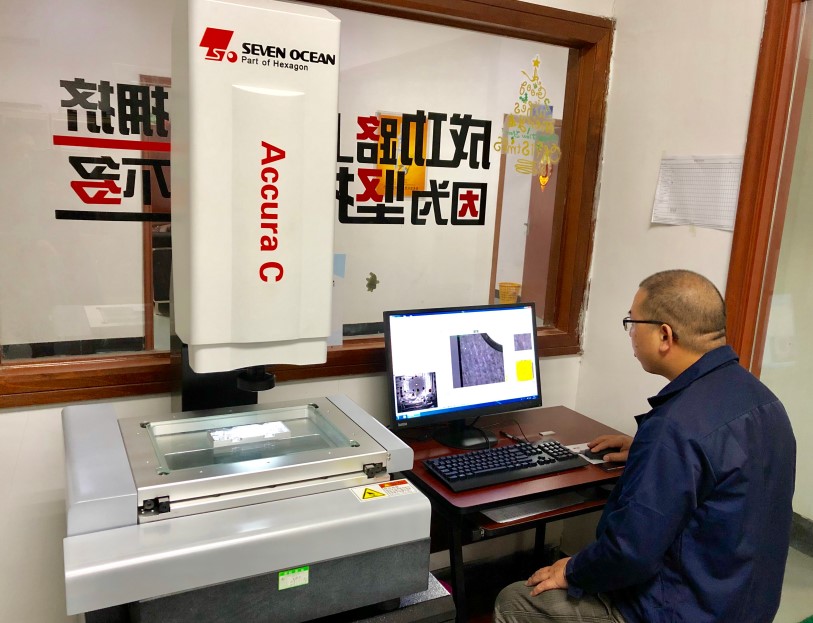

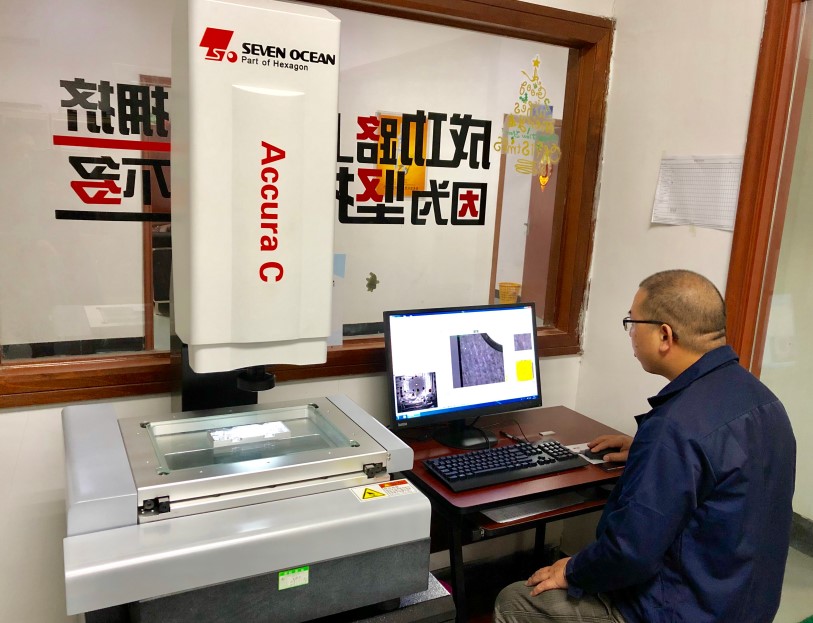

CMM inspection to check the dimensions

Tickness inspection to check the thickness film

Roughness inspection to check the surface roughness

Quality Control

1,Technicians self-check in production

2,Engineer spot check in production

3,QC inspects after mass production finished

4,International sales who were trained the technical know-how spot check before shipping

5,Application expertise.

6,Quality,reliability and long product life.

7,Mature,perfect and excellence.

Projector inspecion to check the dimension

CMM inspection to check the dimensions

Tickness inspection to check the thickness film

Roughness inspection to check the surface roughness