| Availability: | |

|---|---|

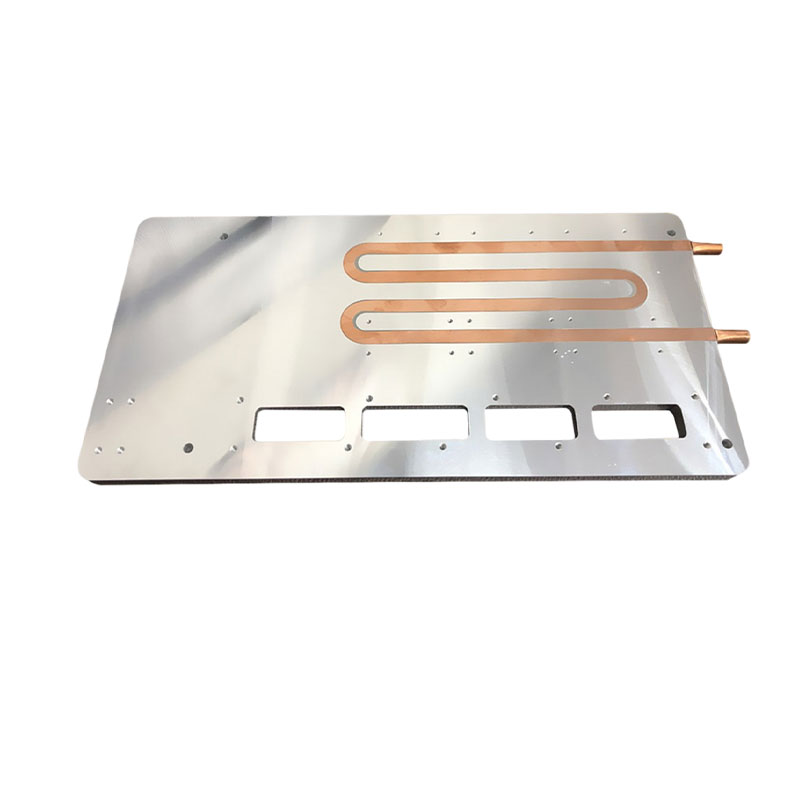

Seamless Joint Integrity: FSW creates strong, defect-free joints that maximize the cold plate’s thermal performance.

Enhanced Durability: The FSW process minimizes stress concentrations, leading to improved mechanical strength and longevity.

Optimized Heat Transfer: Designed to rapidly dissipate heat, ensuring sensitive components remain within safe operating temperatures.

Efficient Liquid Flow: The engineered channel design promotes uniform liquid distribution, reducing the risk of hot spots.

Tailored Solutions: Available in various sizes and configurations to meet the specific thermal management needs of your application.

Compact Design: Ideal for applications with limited space, ensuring a perfect balance between performance and footprint.

High-Performance Materials: Manufactured with premium materials to ensure exceptional thermal conductivity and corrosion resistance.

Versatile Applications: Suitable for use across a range of industries, from high-performance electronics to automotive and aerospace systems.

Electronics Cooling: Ideal for cooling high-power components such as CPUs, GPUs, and power modules in high-performance computing systems.

Automotive Systems: Perfect for use in electric vehicle (EV) battery thermal management and other automotive applications requiring efficient heat dissipation.

Aerospace & Defense: Provides reliable cooling in compact, high-stress environments where durability and precision are critical.

Industrial Power Systems: Suitable for cooling high-energy power supplies and converters, ensuring optimal performance and safety in industrial settings.

Material: Premium metals (customizable based on application)

Cooling Type: Liquid cooling system utilizing engineered flow channels

Manufacturing Process: Friction Stir Welding (FSW) for enhanced joint strength and thermal conductivity

Size/Dimensions: Customizable options available to meet specific application needs

Heat Dissipation Capacity: Designed for high-power applications with significant heat loads

Operating Temperature Range: Optimized for a wide range of industrial and electronic environments

For industries that require both precision and reliability in thermal management, the Friction Stir Welding Process Liquid Cold Plate offers a compelling solution. The integration of advanced FSW technology ensures a product that not only excels in heat dissipation but also maintains structural integrity under demanding conditions. Its customizable design, superior thermal performance, and robust construction make it a top choice for applications ranging from high-performance electronics to critical automotive and aerospace systems.

Seamless Joint Integrity: FSW creates strong, defect-free joints that maximize the cold plate’s thermal performance.

Enhanced Durability: The FSW process minimizes stress concentrations, leading to improved mechanical strength and longevity.

Optimized Heat Transfer: Designed to rapidly dissipate heat, ensuring sensitive components remain within safe operating temperatures.

Efficient Liquid Flow: The engineered channel design promotes uniform liquid distribution, reducing the risk of hot spots.

Tailored Solutions: Available in various sizes and configurations to meet the specific thermal management needs of your application.

Compact Design: Ideal for applications with limited space, ensuring a perfect balance between performance and footprint.

High-Performance Materials: Manufactured with premium materials to ensure exceptional thermal conductivity and corrosion resistance.

Versatile Applications: Suitable for use across a range of industries, from high-performance electronics to automotive and aerospace systems.

Electronics Cooling: Ideal for cooling high-power components such as CPUs, GPUs, and power modules in high-performance computing systems.

Automotive Systems: Perfect for use in electric vehicle (EV) battery thermal management and other automotive applications requiring efficient heat dissipation.

Aerospace & Defense: Provides reliable cooling in compact, high-stress environments where durability and precision are critical.

Industrial Power Systems: Suitable for cooling high-energy power supplies and converters, ensuring optimal performance and safety in industrial settings.

Material: Premium metals (customizable based on application)

Cooling Type: Liquid cooling system utilizing engineered flow channels

Manufacturing Process: Friction Stir Welding (FSW) for enhanced joint strength and thermal conductivity

Size/Dimensions: Customizable options available to meet specific application needs

Heat Dissipation Capacity: Designed for high-power applications with significant heat loads

Operating Temperature Range: Optimized for a wide range of industrial and electronic environments

For industries that require both precision and reliability in thermal management, the Friction Stir Welding Process Liquid Cold Plate offers a compelling solution. The integration of advanced FSW technology ensures a product that not only excels in heat dissipation but also maintains structural integrity under demanding conditions. Its customizable design, superior thermal performance, and robust construction make it a top choice for applications ranging from high-performance electronics to critical automotive and aerospace systems.