Views: 34 Author: Site Editor Publish Time: 2020-06-10 Origin: Site

introduce the cnc toolholder

Numerical control tool to ensure the precision of cnc machining, for precision machining, toolholder is not only a simple clamping tool to buy the vibration of props directly affect the quality of machining surface. Therefore, it is very important to keep uniform cutting force and avoid tool vibration in the process of finishing.

As an intermediate part, the toolholder is connected with the machine tool spindle and the cutting tool tool with the help of the tool handle to transfer the power to the tool blade in order to achieve cutting, if there is no good tool handle, then a good machine tool is futile.

It can be said that the shank system in the cutting process, played a bridge role, that is, a link between the above and below. Bearing is mainly reflected in: some of the spindle performance, torque, speed and other parameters are output through the handle; The opening reflects that the toolholder should be clamped to achieve normal processing.

In a growing number of precision machining applications, grinding, polishing, or etching is no longer required after milling. In these applications, the tool handle system plays a key role in ensuring tool rotation accuracy, compensating vibration, ensuring the accuracy of geometric base surface and perfect machining surface quality.

next,i will introduce some cariety of toolholder to everyone.

Spring toolhoder:

Working principle: the spring clamp sleeve with taper is gradually contracted in the process of axial movement (locking) to realize the clamping tool;

Scope of application: drill, reamer, finishing end mill, etc.

Features: large clamping range;Good versatility;High precision (some manufacturers);

Key points: Whether the spring jacket can shrink perfectly and uniformly is one of the key factors determining the jumping accuracy. The bearing nut can greatly reduce the torque of the jacket during locking.

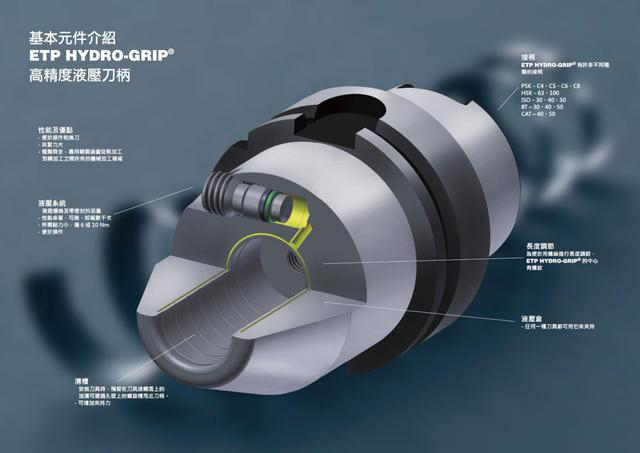

Hydraulic toolhoder:

Working principle: the inner diameter of the handle is shrunk by hydraulic pressure to realize clamping of the cutting tool;

Application: high precision machining of end milling cutter, carbide drill, diamond reamer, etc.

Features: Easy to operate, only one T-wrench can be tightened, which is the simplest clamping method among all the hilts. The accuracy

is stable, and the tightening force does not act on the clamping part directly. Even the new operator can install the clamping part stably.

Completely waterproof and dustproof; Good anti-interference performance, part of the market thin long hydraulic handle, has been

comparable to thermal shrinkage handle anti-interference performance.

Hot toolhoder:

Working principle: the difference of thermal expansion coefficient between the handle and the cutting tool is used to clamp the cutting tool.

Scope of application: machining occasions with high interference requirements;

Features: good interference prevention; Clamping range is small, can only hold one size of cutting tools; The initial runout accuracy

is good (it decreases rapidly with the increase of heating times). Special heating and cooling device is needed, which has poor safety

and high requirements for operators.

Strong milling toolhoder:

Working principle: the body of the handle is compressed by the nut to shrink, and the cutting tool is clamped;

Scope of application: heavy cutting of end mills;

Features: High rigidity; The clamping force is strong, which is the largest among all the clamping grips. Poor interference prevention; (Recently, some manufacturers have introduced the strong milling shank with the outer diameter of nut only 32mm.) The run-out precision is generally below 0.02mm, but some manufacturers have achieved 5-10 m;

Key points: whether the elastic deformation is uniform and whether the shrinkage is sufficient. Chuck thickening design, can increase the rigidity, withstand the end milling cutter's heavy cutting).

Side fixed toolhoder:

Working principle: Locking the cutting tool with side fixed screws;

Scope of application: Rough machining of drills and milling cutters for shank cutting;

Features: simple structure, large clamping force; But the accuracy and generality are poor