Views: 16 Author: Site Editor Publish Time: 2023-08-30 Origin: Site

Welcome to our blog post discussing the materials commonly used in friction stir welded liquid cold plates. Whether you are new to this concept or already familiar, we will provide valuable insights and tips on selecting the suitable materials for your customized liquid cold plate. So, let's dive in!

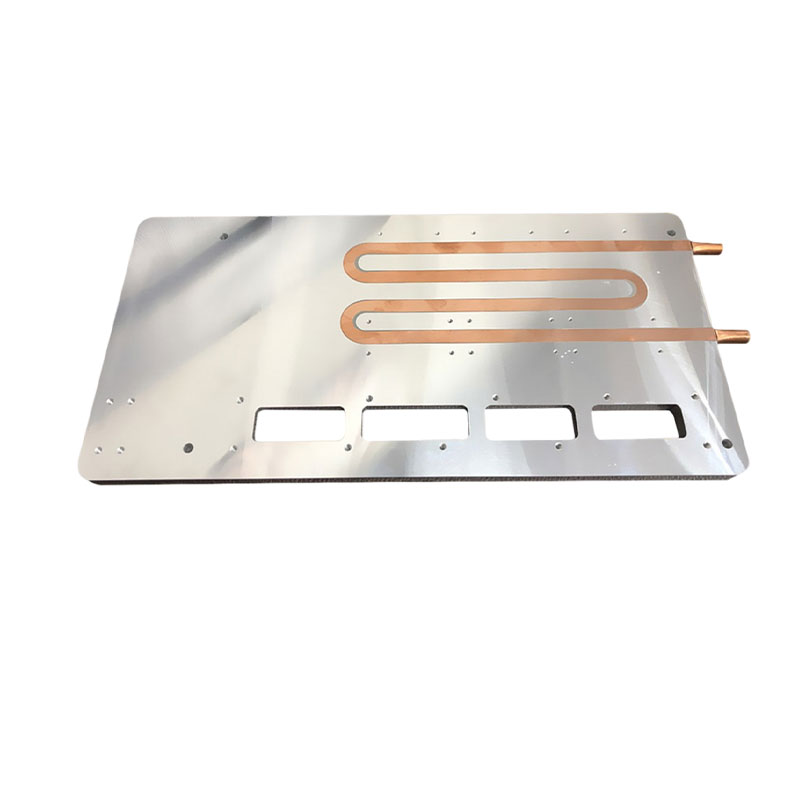

Liquid cold plates have become increasingly popular in various industries, serving as an efficient cooling solution for electronic components. Friction stir welding is a joining technique that offers unique advantages in manufacturing liquid cold plates, enabling the combination of different materials to enhance performance and heat dissipation. This paper examines the most commonly used materials in friction stir welded liquid cold plates and their key characteristics.

Copper-based materials are highly sought for liquid cold plates due to their excellent thermal conductivity and corrosion resistance. They efficiently transfer heat away from hotspots and ensure optimal cooling of electronic components. Copper alloys such as CuCrZr and CuNiSiCr are frequently used in friction-stir welded liquid cold plates.

CuCrZr, also known as C18150, offers exceptional mechanical properties, electrical conductivity, and resistance to thermal fatigue. This material is an excellent choice for applications requiring high strength and wear resistance.

CuNiSiCr, on the other hand, provides enhanced corrosion resistance and high electrical conductivity, making it suitable for liquid cold plates used in harsh environments or where galvanic corrosion could occur.

Aluminum-based materials are widely utilized in liquid cold plates due to their lightweight nature, good thermal conductivity, and cost-effectiveness. Friction stir welded liquid cold plates made from aluminum alloys offer an excellent balance between cooling efficiency and weight reduction.

Aluminum alloy 6061 is commonly used in friction stir welded liquid cold plates. It provides good mechanical strength, high thermal conductivity, and excellent corrosion resistance. Additionally, aluminum alloy 6061 can be easily machined to accommodate various designs and configurations.

Stainless steel is another popular choice for friction stir welded liquid cold plates. Its properties include high strength, corrosion resistance, and the ability to withstand elevated temperatures. Stainless steel grades such as 304 and 316 are commonly used in liquid cold plates. Grade 304 offers good general corrosion resistance, while grade 316 provides enhanced pitting and crevice corrosion resistance. Both rates are suitable for applications in demanding environments involving moisture exposure or corrosive substances.

Titanium is a lightweight, high-strength material widely used in various industries. It's exceptional corrosion resistance and excellent thermal conductivity make it an attractive choice for friction stir welded liquid cold plates. Grade 2 titanium is commonly used in liquid rigid containers due to its good weldability, formability, and mechanical properties. It is particularly well-suited for applications where weight reduction, corrosion resistance, and compatibility with different fluids are essential.

In addition to copper-based materials mentioned earlier, copper alloys with enhanced properties are specifically designed for liquid cooling applications. These alloys offer improved thermal performance, corrosion resistance, and other desirable characteristics. One such copper alloy is CuAg, a silver-enhanced copper alloy. It combines the benefits of silver, such as improved thermal conductivity and antimicrobial properties, with the excellent thermal performance of copper. CuAg is a perfect choice for liquid cold plates in applications where antimicrobial protection and optimal cooling efficiency are crucial.

When selecting materials for friction stir welded liquid cold plates, it is essential to consider factors such as electrical conductivity, compatibility with coolants or fluids, and overall cost-effectiveness. Each application may have specific requirements and constraints influencing the material selection process.

Additionally, optimizing the design and geometric configuration of the liquid cold plate can further enhance its performance. Heat transfer effectiveness can be improved by integrating fins, microchannels, or other internal structures. These design considerations should align with the materials chosen to ensure optimal cooling efficiency.

In conclusion, friction stir welded liquid cold plates offer a versatile cooling solution for various industries. For the overall performance and longevity of these fluid cooling systems, the choice of materials is critical. Copper-based materials, aluminum-based materials, stainless steel, titanium, and copper alloys with enhanced properties are commonly used in friction stir welded liquid cold plates due to their unique properties and advantages. You can ensure optimal cooling performance and reliability by carefully selecting the suitable material for your application, considering thermal conductivity, corrosion resistance, and cost-effectiveness.

If you are interested in customizing friction stir welded liquid cold plates or have further questions, do not hesitate to contact our team of experts. We are here to assist you in finding the perfect solution for your cooling needs.