Views: 1 Author: Site Editor Publish Time: 2026-01-27 Origin: Site

As AI silicon pushes past 500W TDP, the limiting factor for compute performance is no longer clock speed, but Thermal Resistance ($R_{th}$). If heat cannot move from the die to the ambient air fast enough, the system throttles. For thermal engineers and procurement managers, the challenge is clear: standard extruded heat sinks often fail to meet the low thermal resistance requirements of modern GPU / CPU thermal solutions. Optimizing for these high loads requires a deep understanding of manufacturing limits, material conductivity, and advanced fin geometries.

At Kingka Tech, we don't just bend metal; we engineer thermal pathways. Drawing from 13 years of experience completing over 300+ thermal designs, we have analyzed the specific manufacturing trade-offs that lower thermal resistance. Below, we break down how to choose the right architecture for your high-power application.

Why does a massive heat sink sometimes fail to cool a small chip?

To lower temperatures, you must reduce the Total Thermal Resistance ($R_{total}$). This is the sum of three barriers:

Interface Resistance ($R_{tim}$): The bond between chip and base.

Spreading Resistance ($R_{spread}$): Moving heat from the small die to the full base width.

Convection Resistance ($R_{conv}$): Transferring heat from fins to air.

In high-power AI nodes, Spreading and Convection are usually the bottlenecks. A standard aluminum base may not spread heat fast enough (high $R_{spread}$), and standard fin spacing may not offer enough surface area (high $R_{conv}$).

Engineering Insight: You cannot solve a spreading issue by adding taller fins. You need better materials (Copper) or vapor chambers. Conversely, you cannot solve a convection issue with a thicker base; you need denser fins (Skiving).

When should you abandon standard extrusion for advanced manufacturing?

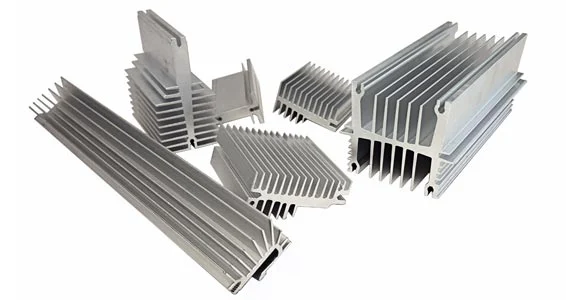

While Extruded heat sinks are the most cost-effective and lightweight option (ideal for auxiliary components), they have a physical limit: the Fin Aspect Ratio.

The Extrusion Limit: Typically, extrusion is limited to a ratio of roughly 10:1 or 15:1 (Fin Height : Gap).

The AI Problem: To cool a 400W+ GPU within a 1U or 2U server chassis, you need massive surface area—often requiring aspect ratios of 40:1 or higher. Extrusion simply cannot achieve this density.

To overcome this, Kingka Tech utilizes alternative manufacturing processes found in our product line:

Skived Fin Heat Sink: We use a precision blade to slice fins from a solid block. This allows for ultra-thin fins (down to 0.2mm) and tight spacing, maximizing surface area for efficient heat exchange in high-velocity airflow environments.

Bonded Fins Heat Sink: We bond separate fins into a grooved base. This allows for extremely tall fins, perfect for High-power heat sinks in industrial racks where space is less constrained.

Is Copper always the right choice for AI workloads?

Material selection is a direct trade-off between performance ($R_{spread}$), weight, and cost.

Aluminum Alloys (AL6063/6061):

Pros: Lightweight, easy to machine, low cost.

Cons: Thermal conductivity (~200 W/m·K) is often insufficient for the extreme power density of AI chips.

Copper (C1100):

Pros: Thermal conductivity (~398 W/m·K) effectively halves spreading resistance. Resistant to thermal corrosion.

Cons: Heavy and expensive.

Kingka Tech Experience:

In our 4000+ manufactured parts, we often implement Hybrid Solutions. For example, we might use a Copper base (to fix $R_{spread}$) swaged to Aluminum fins (to reduce weight). This provides the performance needed for GPU / CPU thermal solutions without the full weight penalty of a solid copper block.

Unsure if you need full copper or a hybrid design? Send us your thermal load data for a material recommendation.

Which manufacturing method yields the lowest Thermal Resistance?

We have compiled a comparison based on typical AI compute node constraints (high power, limited height).

Table 1: Thermal Performance by Manufacturing Process

Feature | Extrusion Heat Sink | Skived Fin Heat Sink | Bonded Fins Heat Sink |

Manufacturing Process | Pushed through die | Sliced from block | Epoxy/Braze attachment |

Fin Aspect Ratio | Low (~10:1) | High (~50:1) | Very High (>60:1) |

Base-to-Fin Resistance | Zero (Monolithic) | Zero (Monolithic) | Low (Dependent on bond) |

Thermal Performance | Good for <150W | Excellent for >400W (Server) | Excellent for High Convection |

Cost | Low | Medium | Medium-High |

Best Application | Memory, VRMs, Edge AI | High-Density GPU/CPU | Inverters, Large Chassis |

Engineering Analysis:

For standard AI servers (1U/2U), Skived Fin Heat Sinks are usually the superior choice because they offer high surface area and zero interface resistance between the fin and base, providing the lowest possible $R_{total}$ in a compact volume.

How do we ensure the design works before tooling begins?

In high-stakes AI hardware, "trial and error" is not an option. Kingka Tech provides a global one-stop thermal management solution that bridges the gap between theory and reality.

Thermal Analysis: Our engineering team simulates airflow and heat dissipation to predict $R_{th}$ accurately.

Design Optimization: We adjust fin geometry (thickness, pitch) to balance thermal performance with pressure drop.

Manufacturing: Whether utilizing CNC precision machining for prototypes or automated skiving for mass production, we ensure the physical part matches the simulation.

Testing: We validate the final $R_{th}$ in our lab to guarantee it meets the TDP requirements of your silicon.

Case Example: We recently optimized a design for a client in the new energy sector. By switching from a bonded fin design to a high-density skived copper design, we reduced the junction temperature by 6°C, keeping the processor well within its safe operating range.

Minimizing thermal resistance in High-power heat sinks is an engineering puzzle that requires matching the right material and manufacturing process to your specific power density.

If you are cooling auxiliary components, Extrusion is cost-effective.

If you are cooling a 500W AI GPU in a server rack, Skived Copper is often the only way to meet the thermal budget.

At Kingka Tech, we combine 13 years of design heritage with advanced manufacturing capabilities to deliver Custom heat sink solutions that perform. We don't just build to print; we build to cool.

Do not let high thermal resistance throttle your AI compute performance.

[Contact Kingka Tech Today] for a free DFM (Design for Manufacturing) review. Let our engineering team analyze your 3D model and propose the most efficient manufacturing path for your next project.