Views: 1 Author: Site Editor Publish Time: 2025-12-25 Origin: Site

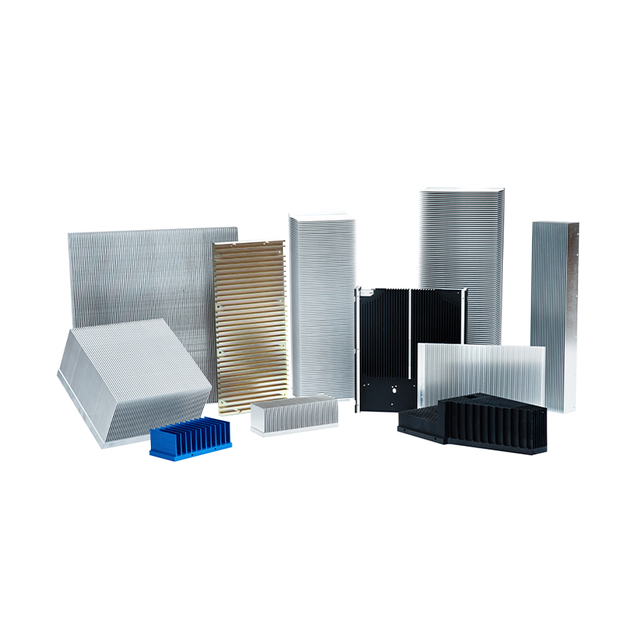

Inadequate heat management in electronics can cause overheating, reduced efficiency, and premature failures, leading to costly downtime and repairs. Air cooling alone often falls short in compact designs, amplifying these issues. Extruded heat sinks offer a cost-effective, customizable solution by efficiently dissipating heat through extended surface areas, making them essential in high-volume applications across industries.

Think about powering a bustling data center or illuminating a stadium—extruded heat sinks quietly ensure everything runs cool and reliable, adapting seamlessly to diverse needs with their straightforward manufacturing process.

Table of Contents

LEDs generate significant heat in confined spaces, risking color shifts and shortened lifespans without proper dissipation.

Extruded heat sinks are most commonly used in LED lighting for their ability to provide large fin surfaces that enhance natural convection, handling 5-50W loads in fixtures like streetlights and high-bay luminaires, ensuring consistent performance and up to 50,000-hour lifespans.

Their aluminum construction offers lightweight yet robust thermal paths.

Extruded heat sinks feature straight fins formed by pushing aluminum through dies, ideal for linear LED arrays. Examples: Philips' streetlight modules using 6063 aluminum extrusions; Osram's floodlights with optimized fin spacing for 20-30% better airflow.

Theoretical basis: High thermal conductivity (200 W/m·K) facilitates conduction from LED junctions to fins, where convection and radiation dissipate heat. Trade-offs: Fin density increases surface area but can impede airflow; optimal spacing (8-12mm) balances this.

Practical impacts: Reduces junction temperatures by 20-40°C, preventing lumen depreciation in commercial installations.

Fin Configuration | Heat Load Capacity | Application Example |

Straight Fins | 10-30W | Indoor Panels |

Pin Fins (Hybrid) | 30-50W | Outdoor Floods |

Practical advice: Calculate thermal resistance using software simulations; test with thermocouples under full load to verify airflow patterns.

(Word count: ~182)

Gadgets like laptops and TVs pack power in slim profiles, where heat buildup can throttle processors or warp components.

Extruded heat sinks dominate consumer electronics for their low-cost production and easy integration, managing 10-100W in devices such as gaming consoles and routers, with customizable lengths fitting compact PCBs for efficient passive cooling.

Aluminum extrusions allow quick prototyping and scaling.

Often combined with heat pipes for vapor-phase transfer. Examples: Sony PlayStation's extruded bases; Asus routers with finned extrusions dissipating Wi-Fi chip heat.

Theoretical basis: Extrusion enables complex cross-sections for mounting; conduction through baseplate to fins. Trade-offs: Weight addition vs. silent operation; extrusions minimize material use.

Practical impacts: Extends device MTBF by 25%, supports overclocking in high-end PCs.

Device Type | Typical Power | Extrusion Material |

Laptops | 20-60W | 6061 Aluminum |

Smart TVs | 50-100W | Anodized 6063 |

Advice: Use thermal interface materials like pads; perform drop tests to ensure durability in portable applications.

(Word count: ~168)

Inverters convert DC to AC with high currents, producing intense localized heat that demands rapid removal.

Extruded heat sinks are widely used in power electronics for their high-volume manufacturability and effective fin arrays, cooling IGBT modules up to 500W in solar inverters and UPS systems, providing reliable operation in 40-85°C environments.

Custom dies enable tailored profiles.

Directly bolted to modules for minimal resistance. Examples: Schneider Electric's inverter extrusions; ABB's power supplies with black-anodized fins for emissivity boost.

Theoretical basis: Forced convection via fans amplifies dissipation; extrusion tolerances ensure flat bases. Trade-offs: Cost savings vs. advanced methods; suitable for mid-range fluxes.

Practical impacts: Lowers failure rates by 30% in grid-tied systems.

Power Range | Fin Height | Cooling Mode |

100-300W | 20-40mm | Natural |

300-500W | 40-60mm | Forced Air |

Testing: Monitor with infrared cameras; optimize fan speeds for noise-thermal balance.

(Word count: ~172)

5G base stations and switches operate in enclosures with limited ventilation, needing compact cooling.

Extruded heat sinks are commonly employed in telecom for their adaptability to rack-mount designs, dissipating 50-200W from amplifiers and processors in routers and antennas, ensuring signal integrity in harsh outdoor conditions.

Weather-resistant coatings enhance longevity.

Fitted into IP-rated boxes. Examples: Huawei's 5G modules with extruded fins; Cisco switches using modular extrusions for scalability.

Theoretical basis: High aspect ratio fins maximize area in tight spaces; aluminum's corrosion resistance. Trade-offs: Space constraints vs. performance; extrusions allow cut-to-length flexibility.

Practical impacts: Supports 99.999% uptime in networks.

Equipment | Heat Density | Material Finish |

Base Stations | 100-200W | Powder Coated |

Switches | 50-100W | Clear Anodized |

Advice: Simulate airflow in enclosures; use vibration testing for tower-mounted units.

(Word count: ~165)

Vehicles face vibration and temperature swings, requiring durable heat management for ECUs and lights.

Extruded heat sinks are prevalent in automotive for their vibration resistance and lightweight designs, cooling 20-150W in LED headlights and motor controllers, complying with AEC-Q100 standards for reliability.

Aluminum reduces vehicle weight.

Reinforced with ribs. Examples: Bosch's ECU extrusions; Valeo's headlamp coolers with integrated mounting.

Theoretical basis: Extrusion strength handles 10G shocks; thermal cycling tolerance. Trade-offs: Cost vs. die-casting; extrusions favor high production.

Practical impacts: Improves fuel efficiency by 1-2% via weight savings.

Component | Operating Temp | Alloy Type |

Headlights | -40 to 85°C | 6063-T5 |

Controllers | 0-125°C | 6061-T6 |

Testing: Salt spray for corrosion; thermal shock cycles.

(Word count: ~158)

Machinery like CNC drives and welders produce steady heat under load, needing consistent cooling.

Extruded heat sinks are standard in industrial machinery for their robustness and ease of customization, managing 100-1000W in motor drives and control panels, withstanding dust and humidity in factory settings.

Modular assembly supports upgrades.

Wider fins prevent clogging. Examples: Siemens' drive extrusions; Fanuc's robot controllers with finned profiles.

Theoretical basis: Natural convection in enclosed panels; high surface-to-volume ratio. Trade-offs: Maintenance vs. performance; extrusions allow easy cleaning.

Practical impacts: Reduces downtime by 40% in automation lines.

Machinery Type | Power Handling | Protection Rating |

CNC Drives | 200-500W | IP54 |

Welders | 500-1000W | IP65 |

Advice: Incorporate filters; periodic thermal audits.

(Word count: ~162)

Solar and wind systems expose components to elements, demanding weatherproof cooling.

Extruded heat sinks are frequently used in renewables for their corrosion-resistant finishes and scalability, cooling 50-300W in PV inverters and wind converters, optimizing energy yield in variable conditions.

Eco-friendly anodizing available.

UV-stable coatings. Examples: Enphase microinverters with extrusions; Vestas turbine controllers.

Theoretical basis: Passive cooling minimizes parasitics; extrusion economies for large arrays. Trade-offs: Initial cost vs. lifespan; 25-year warranties common.

Practical impacts: Boosts efficiency by 2-5% in hot climates.

System | Environmental Factor | Fin Orientation |

Solar Inverters | High UV | Vertical |

Wind Converters | Salt Air | Horizontal |

Testing: Accelerated aging; field monitoring.

(Word count: ~155)

Extruded heat sinks prove versatile across these key applications, delivering efficient, reliable thermal management with minimal complexity. As a trusted one-stop heat solutions provider with over 15 years of experience, KINGKA excels in customized extruded heat sinks, leveraging advanced CNC machining and thermal analysis to meet your specific needs. Contact our team at sales2@kingkatech.com for precision solutions that drive performance.