Views: 198 Author: Site Editor Publish Time: 2025-04-04 Origin: Site

Heatsinks are vital components in electronics, designed to dissipate heat from devices like CPUs, GPUs, LEDs, and power transistors, ensuring optimal performance and longevity. Among the materials used, aluminum is a top choice due to its lightweight nature, excellent thermal conductivity, and affordability. However, anodizing—a process that enhances aluminum’s natural properties—takes these heatsinks to the next level, improving durability, heat dissipation, and even aesthetics.

In this comprehensive guide, we’ll explore what anodized aluminum heatsinks are, how they work, their benefits, and when to use them. Whether you’re an engineer, designer, or hobbyist, you’ll find actionable insights to optimize your thermal management solutions.

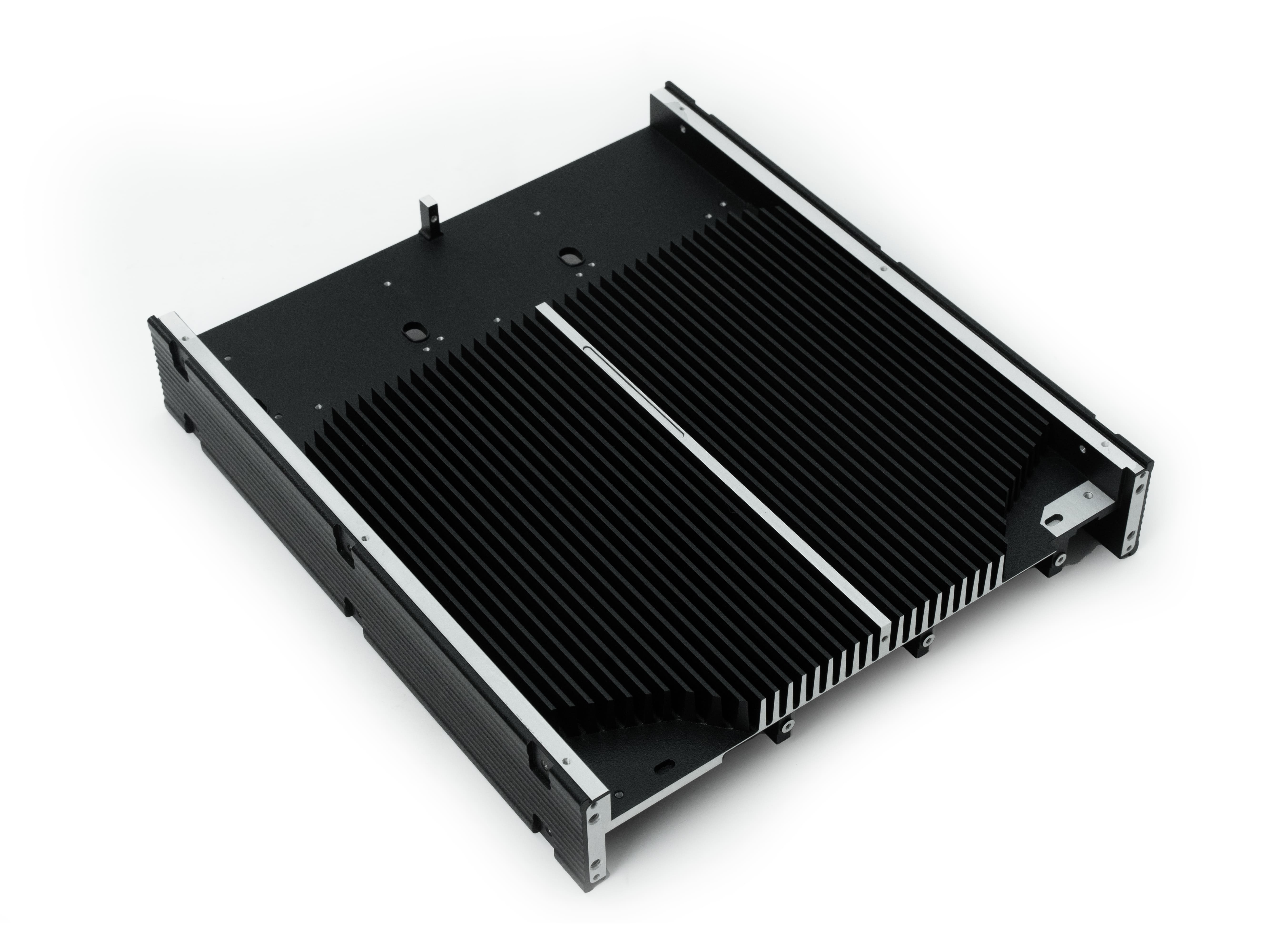

An anodized aluminum heatsink is an aluminum cooling device treated with an electrochemical process called anodizing. This process thickens the naturally occurring oxide layer on aluminum, creating a robust coating that enhances its functionality.

Anodizing involves submerging the aluminum in an electrolytic bath (usually sulfuric acid) and passing an electric current through it. This causes oxygen to bond with the aluminum surface, forming a thicker aluminum oxide layer. The porous nature of this layer allows for additional treatments like coloring or sealing, tailoring the heatsink to specific needs.

There are three primary types of anodizing relevant to heatsinks:

Type I (Chromic Acid Anodizing): Thin coating for basic protection.

Type II (Sulfuric Acid Anodizing): Versatile, moderately thick, and widely used.

Type III (Hard Coat Anodizing): Thick and durable for extreme conditions.

Type II is the most common for heatsinks due to its balance of performance and cost.

Anodizing enhances heatsink performance primarily by boosting emissivity, the ability to radiate heat, which is crucial for passive cooling systems.

Bare aluminum has a low emissivity (~0.05), meaning it reflects heat rather than radiating it. Anodizing increases this to ~0.85, allowing the heatsink to release heat more effectively. This is particularly beneficial in natural convection setups with limited airflow.

While the oxide layer slightly reduces thermal conductivity, its thinness (10-25 microns) ensures this impact is negligible. The overall result is a net gain in heat dissipation, as evidenced by studies showing anodized surfaces radiating up to 15 times more heat than bare aluminum (source: Gabrian).

Anodized aluminum heatsinks offer several advantages:

Corrosion Resistance: Protects against moisture, salt, and chemicals.

Wear Resistance: The hard oxide layer resists physical damage.

Electrical Isolation: Prevents short circuits in tight electronic layouts.

Enhanced Emissivity: Improves passive cooling efficiency.

Aesthetic Options: Allows for colored finishes (e.g., black, silver, blue).

These properties make anodized heatsinks ideal for both functional and visual applications.

Here’s a breakdown of the three main anodizing types:

Type | Thickness | Properties | Applications |

Type I | 0.5-7.5 µm | Thin, basic protection | Aerospace, minimal needs |

Type II | 5-25 µm | Corrosion resistance, dyeable | Electronics, consumer goods |

Type III | 25-150 µm | Thick, durable, wear-resistant | Industrial, harsh settings |

Type I: Rarely used for heatsinks due to limited durability.

Type II: The go-to for most electronics applications.

Type III: Best for rugged environments.

Choose based on your project’s environmental and durability requirements.

Does color matter? It depends on the cooling method:

Natural Convection: Black anodized heatsinks outperform lighter colors by 3-8% due to higher emissivity.

Forced Air Cooling: Color has little impact, as convection dominates.

For aesthetics or branding, black is popular, but performance differences are minor in active cooling setups.

The 6000 series alloys are ideal for heatsinks:

6060: Excellent for extrusion, good conductivity.

6061: Strong, versatile, often machined.

6063: High conductivity, formable, widely used for extrusions.

Pure aluminum, while more conductive, lacks strength, making 6063 a top pick for its balance of properties.

For engineering drawings, include:

Type: E.g., Type II or III.

Thickness: E.g., 15 µm.

Color: E.g., black or clear.

Standards: E.g., MIL-A-8625.

Tolerances: Adjust for the oxide layer’s thickness.

Example: "Anodize per MIL-A-8625, Type II, Class 2, Black, 15 µm."

The oxide layer reduces conductivity slightly, but its thinness makes this negligible. The emissivity gain far outweighs this minor loss, enhancing overall performance.

Not always. Bare aluminum works in:

Indoor, dry environments.

Cost-sensitive projects.

Anodizing is essential for:

Harsh conditions (e.g., outdoor use).

High-reliability needs (e.g., aerospace).

Aesthetic requirements.

The process includes:

Forming: Extrusion, machining, or casting.

Cleaning: Remove contaminants.

Anodizing: Build the oxide layer.

Coloring: Optional dyeing.

Sealing: Lock in properties.

Quality checks ensure consistency in thickness and finish.

They’re used in:

Electronics: CPUs, LEDs, servers.

Automotive: EV batteries, power modules.

Aerospace: Avionics, satellites.

Industrial: Motors, power equipment.

Their versatility suits diverse needs.

No. Thermal interface materials (TIMs) like grease are still needed to fill microscopic gaps and ensure efficient heat transfer, even with anodizing.

Anodized aluminum heatsinks are a cornerstone of effective thermal management, offering unmatched durability, thermal efficiency, and design versatility for demanding applications. At Kingka, we specialize in delivering customized anodized aluminum heatsinks tailored to industries like electronics, automotive, and medical equipment. With over 15 years of expertise, our advanced CNC machining, free thermal design, and rigorous quality control ensure high-performance solutions that meet your unique needs. Explore Kingka’s one-stop thermal solutions to elevate your project’s reliability and efficiency.