Views: 9 Author: Site Editor Publish Time: 2025-11-06 Origin: Site

Choosing the optimal liquid cold plate is critical for high-performance thermal management, but navigating the options—Friction Stir Welded (FSW), Brazed, and Deep-Machined—can be complex. Each manufacturing method offers distinct advantages in thermal performance, structural integrity, cost, and design flexibility. This guide provides a focused comparison, helping you understand which liquid cold plate technology best suits your specific application's heat load, pressure requirements, and budget, ensuring efficient and reliable cooling for your critical components.

In the world of high-power electronics, battery systems, and industrial machinery, air cooling often falls short. When heat loads become intense, liquid cold plates step in as the go-to solution for efficient and reliable thermal management. But not all liquid cold plates are created equal. The manufacturing process profoundly impacts a cold plate's performance, durability, and cost. If you're looking to cool critical components, you've likely encountered terms like FSW, Brazed, and Deep-Machined liquid cold plates. This guide will cut through the jargon, offering a direct, comparative analysis to help you understand the strengths and weaknesses of each, ensuring you select the best liquid cold plate for your specific application.

Deep-Machining Liquid Cold Plates: Precision and Versatility

Brazed Liquid Cold Plates: High Performance and Complex Geometries

Friction Stir Welded (FSW) Liquid Cold Plates: Strength and Reliability

Before diving into specific manufacturing methods, let's establish what makes a liquid cold plate effective.

Liquid cold plates are essential thermal management devices designed to transfer high heat loads from electronic components or power devices to a circulating liquid coolant. Their effectiveness hinges on maximizing the contact area between the heat source and the cold plate, optimizing internal channel design for efficient fluid flow and heat exchange, and ensuring robust, leak-proof construction. Key performance indicators include thermal resistance, pressure drop, and structural integrity, all of which are heavily influenced by the manufacturing process.

At its core, a liquid cold plate is a heat exchanger.

Heat Transfer: A liquid cold plate's primary function is to absorb heat from a component (e.g., IGBT module, CPU, battery cell) and transfer it to a circulating liquid coolant (e.g., water, glycol-water mixture, dielectric fluid).

Key Components:

Base Plate: The surface that contacts the heat-generating component.

Internal Channels: Passageways within the cold plate through which the coolant flows. These are designed to maximize heat transfer surface area and optimize flow.

Inlet/Outlet Ports: Connect the cold plate to the external cooling loop.

Cover Plate (for some types): Seals the internal channels.

Thermal Resistance (Rth): The most critical metric, measured in °C/W. It represents the temperature difference between the heat source and the coolant for a given heat load. Lower Rth means better cooling performance.

Practical Impact: Directly determines how cool your component will run.

Pressure Drop (ΔP): The pressure loss experienced by the coolant as it flows through the cold plate channels. Higher pressure drop requires a more powerful pump, increasing system cost and power consumption.

Practical Impact: Affects pump selection and overall system efficiency.

Flow Rate: The volume of coolant passing through the cold plate per unit time. Higher flow rates generally improve heat transfer but increase pressure drop.

Practical Impact: Must be balanced with pressure drop for optimal system design.

Structural Integrity: The ability of the cold plate to withstand internal fluid pressure, external clamping forces, and thermal cycling without leaking or deforming.

Practical Impact: Crucial for reliability and safety, especially in high-pressure or critical applications.

Weight and Footprint: Physical dimensions and mass, important for space-constrained or weight-sensitive applications.

Practical Impact: Influences overall system design and packaging.

The choice between FSW, Brazed, and Deep-Machined liquid cold plates directly influences all these KPIs. Each method creates different internal channel geometries, material bonds, and structural characteristics, leading to distinct performance profiles. KingKa Tech specializes in all three, offering tailored solutions.

Deep-machining offers unparalleled precision and design flexibility for liquid cold plates.

Deep-machining liquid cold plates are manufactured by precisely milling intricate flow channels directly into a solid block of material, typically aluminum or copper, which is then sealed with a cover plate. This method offers exceptional design flexibility for complex channel geometries, low tooling costs for prototypes and low-volume production, and excellent control over surface finish. While potentially having higher per-unit costs for high volumes, deep-machining provides robust, high-performance cold plates ideal for demanding applications requiring custom designs and precise thermal control.

This method is often the go-to for custom, high-performance, or low-volume applications.

Milling Channels: Flow channels are precisely milled into a solid base plate using CNC (Computer Numerical Control) machines. This allows for highly complex and optimized channel designs, including turbulators, impingement jets, and varying channel widths.

Cover Plate Attachment: Once the channels are milled, a flat cover plate is attached to seal the channels. Common attachment methods include:

Welding: TIG (Tungsten Inert Gas) or Laser welding.

Brazing/Soldering: Using a filler metal to join the base and cover.

Epoxy Bonding: For lower pressure or less critical applications.

Friction Stir Welding (FSW): A solid-state welding process, often used for aluminum.

Design Flexibility: Unmatched ability to create complex, optimized channel geometries (e.g., serpentine, parallel, impingement, micro-channels). This allows for precise flow distribution and heat transfer optimization for specific hot spots.

Example: Designing channels that are denser directly under a high-power chip and wider elsewhere.

Material Choice: Can be made from a wide range of materials, most commonly aluminum (e.g., 6061) and copper, but also stainless steel or other alloys.

Low Tooling Costs: For prototypes and low-volume production, tooling costs are minimal compared to brazing or FSW, as it primarily uses standard CNC machining.

Excellent Surface Finish: CNC machining provides very smooth channel surfaces, which can reduce pressure drop.

Robustness: When properly welded or FSW-sealed, deep-machined cold plates offer excellent structural integrity and leak-proof performance.

Higher Per-Unit Cost (High Volume): For very high volumes, the machining time per unit can make it more expensive than brazing or FSW, which are more automated.

Limited Aspect Ratio: While flexible, there are practical limits to how thin and tall channels can be milled, which can impact the total wetted surface area.

Potential for Leakage (if not properly sealed): The sealing method is critical; a poorly welded or bonded cover plate is a potential leak point.

KingKa Tech's Expertise: With 35 sets of high-end CNC machines and over 15 years of experience, KingKa Tech excels in precision deep-machining liquid cold plates, offering unparalleled customization and quality for demanding applications.

Brazing is a well-established method for creating high-performance, intricate liquid cold plates.

Brazed liquid cold plates are manufactured by joining multiple components, often including internal fin structures, using a filler metal that melts at a lower temperature than the base materials. This process, typically performed in a vacuum furnace, creates robust, leak-proof bonds and allows for complex internal geometries with high surface area-to-volume ratios, such as turbulators or offset strip fins. Brazed cold plates offer excellent thermal performance and structural integrity, making them a preferred choice for high-volume, high-performance applications where intricate internal structures are critical for heat transfer.

Brazing allows for complex internal structures that maximize heat transfer.

Assembly of Components: The cold plate is assembled from multiple pieces: a base plate, internal fin structures (e.g., corrugated fins, offset strip fins, pin fins), and a cover plate. These fins are often stamped or formed.

Filler Metal Application: A brazing filler metal (e.g., aluminum-silicon alloy for aluminum cold plates) is placed at the joints.

Vacuum Brazing: The assembled components are placed in a vacuum furnace and heated to a temperature above the filler metal's melting point but below the base material's melting point. The filler metal melts, flows into the joints by capillary action, and solidifies, creating strong, metallurgical bonds.

Cleaning: Post-brazing cleaning removes any flux residue (if used) or oxides.

High Surface Area: Brazing allows for the integration of very thin, high-density internal fin structures (e.g., corrugated fins, offset strip fins). This significantly increases the wetted surface area for heat transfer, leading to very low thermal resistance.

Example: Offset strip fins create turbulence, enhancing heat transfer coefficients.

Excellent Thermal Performance: Due to the high surface area and often turbulent flow, brazed cold plates offer some of the best thermal performance (lowest Rth) for a given footprint.

Robust, Leak-Proof Bonds: Vacuum brazing creates strong, metallurgical bonds between all components, resulting in a highly reliable and leak-proof structure capable of withstanding high pressures.

Cost-Effective for High Volume: Once tooling is established for the fin structures and plates, brazing can be a very cost-effective manufacturing method for high-volume production.

Material Compatibility: Commonly used for aluminum (e.g., 3003/6061 with 4047 filler) and copper alloys.

High Tooling Costs: Significant upfront investment in tooling for fin stamping and assembly fixtures.

Less Design Flexibility (for channels): While internal fin structures are flexible, the overall channel path is often simpler (e.g., serpentine) compared to deep-machined plates.

Minimum Order Quantities (MOQs): Due to tooling costs, brazed cold plates are typically not cost-effective for low-volume or prototype runs.

Potential for Filler Metal Issues: Improper brazing can lead to voids or excess filler metal, impacting performance or reliability.

KingKa Tech's Expertise: With extensive experience in thermal management, KingKa Tech provides high-quality brazed liquid cold plates, leveraging intricate fin designs for superior heat transfer in high-volume applications.

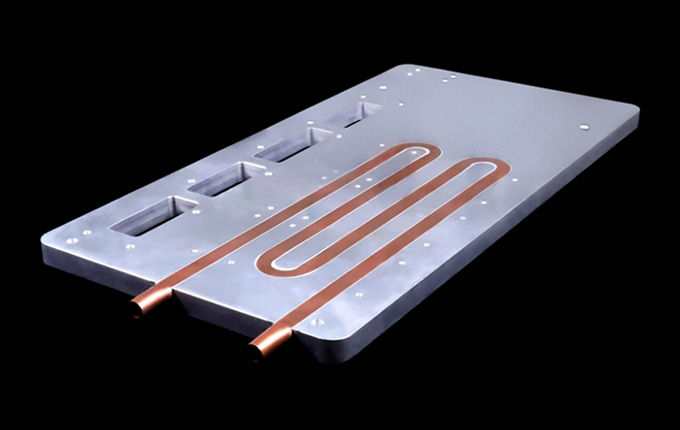

FSW offers a unique solid-state welding approach for robust liquid cold plates.

Friction Stir Welded (FSW) liquid cold plates are manufactured by joining a base plate with milled channels and a cover plate using a solid-state welding process that generates heat through friction, softening the material without melting it. This results in an extremely strong, low-distortion, and porosity-free weld, making FSW cold plates exceptionally reliable and leak-proof, particularly for aluminum. FSW is ideal for applications demanding high structural integrity, high internal pressures, and long-term durability, offering a robust alternative to traditional welding or brazing.

FSW is a relatively newer technology that offers distinct advantages, especially for aluminum.

Milling Channels: Similar to deep-machining, channels are milled into a base plate.

Cover Plate Placement: A flat cover plate is placed over the milled channels.

Friction Stir Welding: A non-consumable rotating tool with a specially designed pin and shoulder is plunged into the joint line between the base and cover plates.

Friction Heat: The rotating tool generates frictional heat, softening the material.

Material Flow: The pin stirs and forges the softened material, creating a solid-state bond without melting.

No Filler Metal: No filler metal, flux, or shielding gas is typically required.

Post-Processing: Minimal post-weld cleaning is usually needed.

Superior Weld Strength: FSW creates a fine-grained, recrystallized microstructure in the weld zone, often resulting in a weld that is stronger than or equal to the parent material. This is crucial for high-pressure applications.

Low Distortion: Since the material doesn't melt, FSW produces very low thermal distortion and residual stress, leading to flatter, more dimensionally stable cold plates.

No Porosity/Cracking: The solid-state nature of FSW eliminates common weld defects like porosity, cracking, and hot tearing.

Environmentally Friendly: No fumes, flux, or shielding gases, making it a cleaner process.

Excellent for Aluminum: FSW is particularly effective for aluminum alloys, which can be challenging to weld with traditional fusion methods.

Reliability: The robust, defect-free welds contribute to exceptional long-term reliability and leak-proof performance, even under thermal cycling and high pressures.

Design Flexibility (Channels): Similar to deep-machining, FSW can seal complex milled channels.

Higher Equipment Cost: FSW machines are specialized and expensive.

Limited Material Combinations: Primarily used for aluminum and some copper alloys; less versatile for dissimilar metals than brazing.

Access Requirements: The FSW tool requires access to the weld line, which can limit certain geometries or tight corners.

Tooling Marks: The FSW process leaves a characteristic "stir zone" mark on the surface.

Not Ideal for Very Thin Materials: Requires a certain material thickness for the tool to operate effectively.

KingKa Tech's Expertise: As a leader in thermal solutions, KingKa Tech offers FSW liquid cold plates, renowned for their superior structural integrity and reliability, especially for high-pressure aluminum applications.

A direct comparison of FSW, Brazed, and Deep-Machined liquid cold plates clarifies their performance profiles.

A direct comparative analysis reveals that Brazed liquid cold plates generally offer the lowest thermal resistance due to their high internal surface area from intricate fin structures, making them ideal for maximum heat transfer. Deep-machined cold plates provide unparalleled design flexibility for precise thermal control and lower pressure drop with optimized channels. FSW cold plates excel in structural integrity and reliability, particularly for high-pressure aluminum applications, offering robust, leak-proof performance. Pressure drop and cost-effectiveness at different volumes are also critical differentiators.

Here's a side-by-side look at how these technologies stack up:

Feature | Deep-Machining Cold Plates | Brazed Cold Plates | FSW Cold Plates |

Thermal Resistance (Rth) | Good to Excellent (depends on channel complexity) | Excellent (Lowest Rth due to high surface area fins) | Good to Excellent (depends on channel complexity) |

Pressure Drop (ΔP) | Good (can be optimized for low ΔP with smooth channels) | Higher (due to turbulent flow from intricate fins) | Good (can be optimized for low ΔP with smooth channels) |

Structural Integrity | Excellent (with proper welding/FSW sealing) | Excellent (strong metallurgical bonds) | Superior (strongest, most reliable welds for aluminum) |

Design Flexibility | Excellent (custom channel geometries) | Good (for internal fin structures, less for overall path) | Excellent (for custom channel geometries) |

Material Choice | Wide (Al, Cu, SS) | Limited (Al, Cu) | Limited (Primarily Al, some Cu) |

Surface Finish | Excellent (milled channels) | Good (internal fins can be rougher) | Excellent (milled channels) |

Leak-Proofness | Excellent (with proper sealing) | Excellent | Superior |

Maximum Thermal Performance: If achieving the absolute lowest thermal resistance is paramount, Brazed cold plates often lead due to their ability to integrate high-density internal fins.

Custom Channel Optimization: For precise control over flow distribution and heat transfer to specific hot spots, Deep-Machining and FSW (which uses deep-machined channels) offer superior flexibility.

Structural Robustness: For applications with high internal pressures or where long-term reliability is critical, FSW cold plates (especially for aluminum) provide unmatched weld strength and integrity. Brazed cold plates are also very robust.

Pressure Drop: Deep-machined and FSW cold plates can be designed with smoother, optimized channels for lower pressure drop, whereas brazed plates with intricate fins often incur higher pressure drop.

The "best" liquid cold plate depends on balancing these critical performance metrics against your specific application's needs.

The choice of manufacturing method significantly impacts the design possibilities and material options for liquid cold plates.

The design flexibility of liquid cold plates varies significantly by manufacturing method: deep-machining and FSW allow for highly customized, intricate channel geometries directly milled into the base, offering precise thermal control. Brazing, while excellent for integrating high-surface-area internal fin structures, has less flexibility in overall channel path design. Material considerations are also crucial, with aluminum and copper being primary choices, each offering distinct thermal and cost profiles that must align with the chosen manufacturing process and application requirements.

Understanding these aspects is key to optimizing your cold plate.

Deep-Machining:

Pros: Unparalleled freedom to design complex, multi-pass, variable-width, or impingement channels. Ideal for targeting specific hot spots. Can integrate features like mounting holes directly into the base.

Cons: Limited by tool access for very deep or narrow features.

Brazing:

Pros: Excellent for integrating high-density internal fin structures (e.g., offset strip fins, louvered fins) that maximize wetted surface area and induce turbulence. Allows for very thin fin walls.

Cons: Overall channel path is often simpler (e.g., serpentine). Less flexible for creating highly customized, localized flow patterns compared to deep-machining.

FSW:

Pros: Similar design flexibility to deep-machining for internal channels, as it typically seals milled channels.

Cons: The FSW tool requires access to the weld line, which can impose some geometric constraints on the outer perimeter or internal features.

Aluminum (e.g., 6061, 6063):

Pros: Lightweight, good thermal conductivity (180-220 W/m·K), cost-effective, excellent machinability. Good corrosion resistance with proper coolant.

Manufacturing Compatibility: Compatible with Deep-Machining, Brazing (with specific alloys like 3003/4047), and FSW.

Applications: General electronics, automotive, industrial.

Copper (e.g., C11000):

Pros: Excellent thermal conductivity (380-400 W/m·K), superior for high-power density applications.

Manufacturing Compatibility: Compatible with Deep-Machining and Brazing. FSW is possible but less common than for aluminum.

Applications: High-performance computing (CPUs, GPUs), power electronics (IGBTs), laser diodes.

Stainless Steel:

Pros: Excellent corrosion resistance, high strength.

Manufacturing Compatibility: Compatible with Deep-Machining and Brazing.

Cons: Lower thermal conductivity than Al or Cu, higher cost.

Applications: Medical, food processing, corrosive environments.

KingKa Tech's Expertise: Our experienced R&D team provides free technical design support, helping you select the optimal material and design for your liquid cold plate, considering both thermal performance and manufacturing feasibility.

The chosen manufacturing method for liquid cold plates has significant implications for both process complexity and overall cost.

The manufacturing process and associated costs for liquid cold plates vary significantly: Deep-machining offers low tooling costs for prototypes and low-to-medium volumes but can have higher per-unit costs for mass production due to machining time. Brazing involves high upfront tooling costs but becomes very cost-effective for high-volume production of intricate designs. FSW, while requiring specialized equipment, provides a robust, high-quality weld that can be cost-effective for high-reliability aluminum cold plates in medium-to-high volumes, balancing strength with efficiency.

Understanding these trade-offs is crucial for project budgeting and scalability.

Process: CNC milling, followed by sealing (welding, FSW, brazing, or epoxy).

Tooling Cost: Low. Primarily uses standard CNC tools. Minimal upfront investment.

Per-Unit Cost: Medium to High. Dependent on machining time and complexity. Can be higher for high volumes compared to brazing.

Lead Time: Relatively short for prototypes and small batches.

Best For: Prototypes, low-to-medium volume production, highly customized designs, applications requiring quick turnaround.

Process: Stamping/forming of fins and plates, assembly, vacuum brazing.

Tooling Cost: High. Significant investment in dies for stamping fins and plates, and assembly fixtures.

Per-Unit Cost: Low to Medium. Very cost-effective for high-volume production once tooling is amortized.

Lead Time: Longer for initial tooling, but efficient for mass production.

Best For: High-volume production, applications requiring maximum thermal performance from intricate internal structures, where upfront tooling cost is justified.

Process: CNC milling of channels, FSW sealing.

Tooling Cost: Medium. Requires specialized FSW equipment, but channel milling uses standard CNC tools.

Per-Unit Cost: Medium. Efficient for medium-to-high volumes, balancing machining time with the speed of FSW.

Lead Time: Moderate, dependent on FSW machine availability.

Best For: Medium-to-high volume production of aluminum cold plates requiring superior weld strength, reliability, and low distortion, especially for high-pressure applications.

Manufacturing Method | Tooling Cost | Per-Unit Cost (High Volume) | Key Benefit |

Deep-Machining | Low | Medium-High | Design Flexibility, Low Volume Cost |

Brazing | High | Low-Medium | Highest Thermal Performance, High Volume Cost |

FSW | Medium | Medium | Superior Weld Strength, Reliability |

KingKa Tech's Commitment: We provide transparent cost analysis and work with you to select the most cost-effective manufacturing method that meets your performance and volume requirements, ensuring optimal value for your investment.

The optimal liquid cold plate manufacturing method is dictated by the specific demands of the application.

Matching the liquid cold plate manufacturing technology to the application is crucial for optimal performance and cost-effectiveness. Deep-machined cold plates are ideal for prototypes, low-volume, or highly customized designs requiring precise thermal control. Brazed cold plates excel in high-volume, high-performance applications demanding the lowest thermal resistance from intricate internal fins. FSW cold plates are best suited for applications requiring superior structural integrity, high-pressure resistance, and long-term reliability, particularly with aluminum, such as in power electronics or EV battery cooling.

Here's a guide to help you match the technology to your needs:

Best For:

Prototypes and Low-Volume Production: Where tooling costs for brazing or FSW are prohibitive.

Highly Customized Thermal Profiles: When specific hot spots need targeted cooling with unique channel geometries.

Complex Component Integration: When the cold plate needs to integrate intricate mounting features or interfaces.

Applications: Medical devices, aerospace prototypes, specialized industrial equipment, custom power modules.

Example: A custom cold plate for a unique scientific instrument with varying heat loads across its surface.

Best For:

Highest Heat Flux Applications: Where achieving the absolute lowest thermal resistance is paramount.

High-Volume Production: When the upfront tooling cost can be amortized over many units.

Compact Designs: When maximum heat transfer needs to be packed into a small footprint.

Applications: High-performance computing (data centers, supercomputers), automotive power electronics (e.g., inverters), battery cooling for EVs, industrial lasers.

Example: Cooling IGBT modules in an electric vehicle's power inverter, where high heat loads and compact size are critical.

Best For:

High-Pressure Applications: Where structural integrity and leak-proof performance are critical.

High-Reliability Requirements: For long-life applications under thermal cycling or vibration.

Aluminum-Based Systems: When the benefits of aluminum (lightweight, cost) are desired, but traditional welding limitations are a concern.

Applications: EV battery cooling (for robust, leak-proof packs), industrial power supplies, telecommunications equipment, aerospace components.

Example: A cold plate for a large-scale battery energy storage system, where long-term reliability and resistance to internal pressure are essential.

KingKa Tech's Expertise: Our team can analyze your application's specific requirements—heat load, pressure, volume, budget, and reliability—to recommend the most suitable liquid cold plate manufacturing technology.

Choosing between FSW, Brazed, and Deep-Machined liquid cold plates is a critical decision for effective thermal management.

In conclusion, selecting the optimal liquid cold plate technology—Friction Stir Welded (FSW), Brazed, or Deep-Machined—requires a comprehensive understanding of your application's specific thermal, structural, and cost requirements. Deep-machining offers unparalleled design flexibility for custom, low-volume needs, while brazing excels in high-volume, high-performance scenarios demanding the lowest thermal resistance. FSW provides superior structural integrity and reliability for high-pressure aluminum applications. A strategic choice, balancing thermal performance, pressure drop, structural robustness, and manufacturing cost, is essential for ensuring efficient, reliable, and cost-effective cooling for your critical components.

Each manufacturing method offers distinct advantages:

Deep-Machining: Best for precision, customization, and low-to-medium volumes, offering unmatched design flexibility.

Brazing: Ideal for maximum thermal performance and high-volume production, leveraging intricate internal fin structures.

FSW: Superior for structural integrity, reliability, and high-pressure applications, especially with aluminum.

The "best" liquid cold plate is not a universal product but a carefully selected solution that perfectly aligns with your project's unique demands. By understanding the nuances of each technology, you can make an informed decision that optimizes both performance and cost.

Need expert guidance in selecting and manufacturing the ideal liquid cold plate for your application? KingKa Tech is your trusted one-stop thermal solution provider, specializing in FSW, Brazed, and Deep-Machined liquid cold plates. With over 15 years of experience, advanced manufacturing capabilities, and a dedicated R&D team, we offer free technical design support, thermal analysis, and precision manufacturing to ensure your critical components stay cool and reliable. Contact us today to discuss your project!