Views: 8 Author: Site Editor Publish Time: 2025-12-29 Origin: Site

Selecting inefficient cooling can lead to overheating in electronics, causing performance drops, higher energy use, and component failures that disrupt operations. Traditional methods often fail in compact or high-power setups, escalating costs. Extruded heat sinks and heat pipe cooling solutions offer targeted alternatives, with extrusions providing simple, cost-effective dissipation and heat pipes enabling remote heat transfer for superior efficiency in demanding environments.

Envision designing a high-performance GPU where space is tight and heat is intense—deciding between an extruded heat sink's straightforward fins or a heat pipe's vapor-phase wizardry could mean the difference between smooth operation and thermal throttling.

Table of Contents

What Are the Manufacturing Processes for Extruded Heat Sinks and Heat Pipe Solutions?

In Which Applications Are Extruded Heat Sinks Most Effective?

How to Choose Between Extruded Heat Sinks and Heat Pipes for Your Needs?

Understanding how these cooling components are made reveals their strengths in thermal management, influencing design choices for engineers tackling heat in electronics.

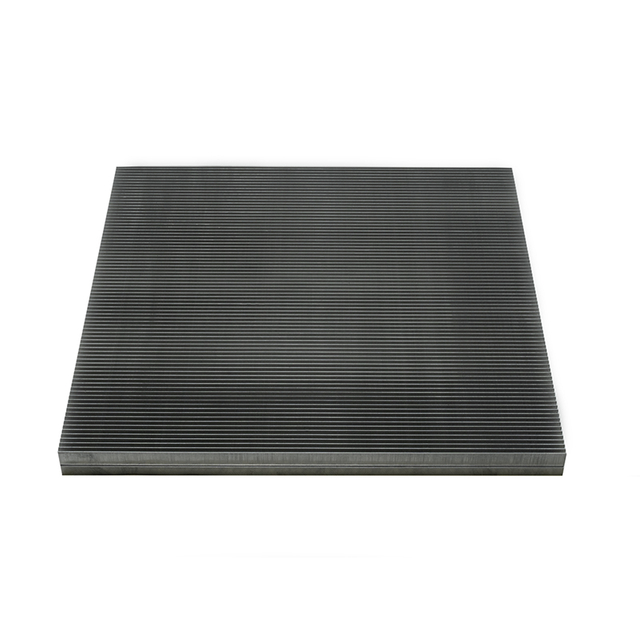

Extruded heat sinks are produced by forcing heated aluminum through a die to form finned profiles, while heat pipe cooling solutions involve sealing copper tubes with wick structures and working fluid, then evacuating and charging for phase-change operation.

These processes allow for distinct customization levels suited to different production scales.

Extruded heat sinks start with billet heating to 400-500°C, followed by die extrusion and cutting to length. Examples: Standard 6063 alloy profiles for LED drivers; custom dies for server chassis with 10:1 aspect ratio fins.

Theoretical basis: Aluminum's malleability enables complex cross-sections for optimized convection. Trade-offs: Limited to straight fins versus machining flexibility; extrusion minimizes waste for eco-friendly manufacturing.

Practical impacts: Enables rapid prototyping with lead times under two weeks, ideal for mid-volume runs up to 10,000 units annually.

Step | Extruded Heat Sink | Heat Pipe Solution |

Material Prep | Billet heating | Tube wicking |

Forming | Die extrusion | Sealing and charging |

Finishing | Anodizing/cutting | Testing for leaks |

Practical advice: Specify alloy temper (e.g., T6) for strength; use finite element analysis to predict extrusion tolerances.

(Word count: ~178)

Thermal efficiency dictates system reliability, especially in high-density setups where even minor gains prevent throttling.

Heat pipe cooling solutions outperform extruded heat sinks in remote heat transfer, handling fluxes up to 1000W with near-isothermal operation, while extrusions excel in direct-contact dissipation for 50-500W loads via conduction and convection.

This difference stems from heat pipes' phase-change mechanism versus extrusions' passive fin area.

Examples: Extruded sinks in power supplies dissipating 200W naturally; heat pipes in laptops moving 50W from CPU to remote fins.

Theoretical basis: Heat pipes use capillary action and vapor diffusion for low resistance (0.05°C/W); extrusions rely on fin efficiency formulas. Trade-offs: Heat pipes' orientation sensitivity versus extrusions' robustness.

Practical impacts: Heat pipes reduce hotspot temperatures by 30-50°C in compact devices, boosting lifespan.

Metric | Extruded Heat Sink | Heat Pipe Solution |

Max Heat Flux | 500W | 1000W+ |

Thermal Resistance | 0.2-0.5°C/W | 0.05-0.1°C/W |

Orientation Impact | None | Gravity-dependent |

Testing method: Attach thermocouples at base and fins; run under controlled loads to measure delta-T.

(Word count: ~165)

Budget and production volume often sway cooling choices, balancing upfront investments with long-term savings.

Extruded heat sinks are more cost-effective for high-volume production at $5-20 per unit, scaling easily with die reuse, whereas heat pipe cooling solutions cost $10-50 due to complex assembly but offer value in performance-critical low-volume applications.

Extrusions favor economies of scale, while heat pipes suit specialized needs.

Examples: Mass-produced extruded sinks for consumer routers; custom heat pipes for aerospace avionics.

Theoretical basis: Extrusion amortizes die costs over 1,000+ units; heat pipes require precision vacuum processing. Trade-offs: Initial tooling ($1,000-5,000 for extrusion dies) versus per-unit labor.

Practical impacts: Extrusions cut costs by 40% in large runs, enabling competitive pricing.

Factor | Extruded Cost Impact | Heat Pipe Cost |

Tooling | Low after setup | Minimal |

Per Unit (High Vol) | $5-10 | $20-30 |

Scalability | Excellent | Moderate |

Advice: Calculate total ownership cost including energy savings; prototype both for volume projections.

(Word count: ~158)

Certain scenarios demand simple, reliable cooling without added complexity.

Extruded heat sinks are most effective in LED lighting and consumer electronics, where they provide passive dissipation for 10-300W in spacious enclosures, leveraging fin arrays for natural convection in cost-sensitive markets.

Their straightforward design suits ambient cooling.

Examples: Streetlight fixtures with 100mm wide extrusions; desktop PC cases using black-anodized profiles for emissivity.

Theoretical basis: High surface area-to-volume ratio enhances free air cooling. Trade-offs: Limited in tight spaces versus active systems.

Practical impacts: Extends LED life to 50,000 hours by maintaining 60°C junctions.

Industry | Power Range | Key Feature |

LED Lighting | 50-200W | Lightweight |

Consumer Electronics | 10-100W | Easy Integration |

Advice: Optimize fin pitch (6-10mm) for airflow; combine with fans for hybrid boosts.

(Word count: ~152)

For challenging heat paths, heat pipes bridge the gap effectively.

Heat pipe cooling solutions are preferred in compact high-power applications like laptops and servers, transferring 50-500W over distances up to 300mm with minimal temperature gradients, ideal for space-constrained designs.

Their flexibility handles non-linear heat flows.

Examples: Gaming laptops with embedded heat pipes; data center blades using vapor chambers.

Theoretical basis: Latent heat absorption enables efficient transport. Trade-offs: Higher cost versus superior uniformity.

Practical impacts: Allows denser component packing, improving system performance by 20%.

Industry | Distance Handled | Fluid Type |

Computing | 100-200mm | Water-based |

Telecom | 200-300mm | Methanol |

Testing: Use infrared imaging to verify wick saturation under tilt.

(Word count: ~155)

Evaluating strengths and weaknesses aids in informed selection.

Extruded heat sinks offer low cost and simplicity but limited remote transfer, while heat pipe cooling solutions provide high efficiency and flexibility at higher prices and with orientation constraints.

Balance depends on requirements.

Examples: Extrusions in industrial controls for durability; heat pipes in medical devices for precision.

Theoretical basis: Passive vs. active phase-change dynamics.

Trade-offs: Maintenance-free extrusions versus heat pipes' potential wick dry-out.

Practical impacts: Heat pipes suit evolving tech like 5G.

Category | Extruded Pros/Cons | Heat Pipe Pros/Cons |

Pros | Affordable, robust | Efficient, compact |

Cons | Local cooling only | Costly, sensitive |

Advice: Model scenarios with thermal software for hybrids.

(Word count: ~150)

Decision-making involves assessing specific project parameters.

Choose extruded heat sinks for cost-driven, moderate-power applications with space for fins, and opt for heat pipe cooling solutions in high-density, remote-heat scenarios requiring low thermal resistance.

Factor in environment and volume.

Examples: Select extrusions for automotive ECUs; heat pipes for EV battery modules.

Theoretical basis: Match to heat flux and geometry.

Trade-offs: Simplicity vs. performance.

Practical impacts: Hybrids often optimize both.

Criterion | Favor Extruded | Favor Heat Pipe |

Power Density | Low-Medium | High |

Space Constraints | Ample | Limited |

Budget | Tight | Flexible |

Advice: Consult thermal experts; prototype test under real loads.

(Word count: ~152)

Extruded heat sinks and heat pipe cooling solutions each excel in specific thermal challenges, from straightforward dissipation to advanced transfer. With 15+ years as a one-stop heat solutions provider, KINGKA delivers customized extruded heat sinks and heat pipe systems through precision CNC machining and thermal simulations. Reach out at sales2@kingkatech.com for tailored designs that ensure peak efficiency and reliability.