Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

The most common mistake in heat sink design is assuming that more fins always equal better cooling. While increasing fin density does increase the surface area available for heat transfer, it also increases hydraulic resistance (pressure drop). If the fin geometry is too dense for the fan’s static pressure capabilities, airflow stalls, and the heat sink fails. Optimizing heat sink fin geometry requires a precise calculation of the "Goldilocks zone"—where surface area is maximized without choking the airflow required to carry the heat away.

For product designers and procurement managers, understanding this trade-off is the difference between a prototype that works in simulation and a product that survives in the field. Below, I break down how to choose the right geometry and the manufacturing process that supports it.

Why does adding more fins sometimes make the system hotter?

Inheat sink design, the goal is to lower thermal resistance ($R_{th}$). The theoretical formula suggests that increasing the surface area ($A$) reduces resistance. However, this assumes constant airflow velocity.

In the real world, as you pack fins closer together (increasing fin density), you create a wall that air struggles to push through.

Low Fin Density: Low pressure drop, but limited surface area for heat exchange.

High Fin Density: Massive surface area, but requires a high-static-pressure fan (which is loud and expensive) to force air through the gaps.

Engineering Advice:

Don't just look at the heat sink. Look at the fan curve (P-Q curve). A passive heat sink (natural convection) needs wide fin spacing (typically >6mm) to allow buoyancy-driven airflow. An active server cooler can handle tight spacing (<1.5mm) but requires a screaming fan.

You can design the perfect shape in CAD, but can it be made?

Different fin geometries require specific manufacturing techniques. At Kingka Tech, we employ a range of processes—Extrusion, Forging, Casting, Stamping, CNC Precision Machining, Skiving, and Swaging—to achieve the required aspect ratios.

Selecting the right method is critical for Custom heat sink solutions:

Geometry: Fixed fin thickness and spacing.

Limit: The "Fin Aspect Ratio" (height-to-gap) is usually limited to 8:1 or 10:1.

Best For: General electronics and LED applications where weight and cost are primary drivers.

Kingka Note: We recommend Extrusion Heat Sinks for lightweight designs where extreme thermal density isn't the bottleneck.

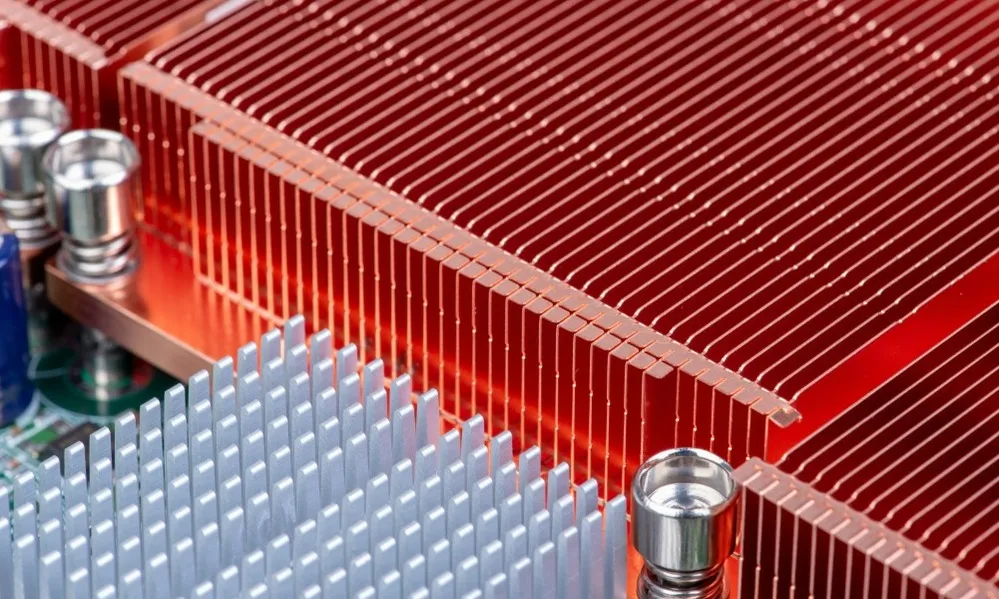

Geometry: Ultra-thin fins sliced from the base block.

Limit: Can achieve very high aspect ratios (up to 50:1) with very thin fins (0.2mm).

Best For: Skived Fin Heat Sinks are ideal for high-performance applications (like servers) where you need maximum surface area in a confined space. Since the fins and base are one piece, there is zero interface thermal resistance.

Geometry: Fins are manufactured separately and attached to a grooved base via thermal epoxy or mechanical swaging.

Limit: Allows for much taller fins than extrusion or skiving.

Best For: Bonded Fins Heat Sinks are the go-to for high-power industrial inverters or rectifiers requiring massive convective cooling.

Does the material choice dictate the geometry?

Yes. While aluminum (typically AL6063 or AL6061) is lightweight, easy to machine, and cost-effective, it has lower thermal conductivity (~200 W/m·K) compared to copper (~400 W/m·K).

Aluminum: Best for extruded or bonded fins where weight is a concern (e.g., Automotive).

Copper: Essential for the base plate or skived fins in high-heat-flux applications (e.g., GPU cooling), despite the weight penalty and higher cost.

Pro Tip:

We often engineer hybrid solutions—using a copper base for rapid heat spreading and aluminum fins for dissipation. This creates a balanced heat sink design that optimizes both performance and cost.

What have we learned from 13 years of data?

Over the past decade, Kingka Tech has completed over 300+ designs and manufactured 4000+ unique thermal management parts. Here is how we typically match geometry to industry needs:

Challenge: Limited space, vibration, weight sensitivity.

Solution: Extrusion Heat Sink.

Why: Aluminum extrusion offers the best structural integrity-to-weight ratio. We use CNC precision machining to trim the extrusion to fit complex housing shapes.

Challenge: Extreme heat density, high-velocity airflow available.

Solution: Skived Fin Heat Sink (Copper).

Why: We use skiving to create thin, dense copper fins. This maximizes the wetted surface area within the 1U or 2U height limit, taking full advantage of the high-static-pressure server fans.

Challenge: Massive heat load (kW range), natural or low-speed convection.

Solution: Bonded Fins Heat Sink.

Why: We bond tall, thick aluminum fins to a heavy base. The wide spacing allows air to flow easily (low pressure drop), which is critical when relying on natural convection or quiet fans.

How do you know it will work before you cut metal?

Guesswork is expensive. At Kingka Tech, we offer a global one-stop solution that includes thermal analysis and design optimization before manufacturing begins.

DFM (Design for Manufacturing): We review your 3D model to ensure the fin aspect ratios are achievable via the chosen process (e.g., verifying skiving tool clearance).

Simulation: We simulate the airflow and heat spread to predict $\Delta T$ (temperature rise).

Validation: From CNC prototyping to mass production, we test the final assembly to ensure it meets the thermal specs.

Are you unsure if your current fin geometry is manufacturable? Send us your STEP file for a quick DFM check.

Optimizing heat sink fin geometry is not about maximizing one variable; it is about balancing surface area, pressure drop, and manufacturing feasibility.

Use Skived Fins when you need maximum density in a small space.

Use Extrusion for cost-sensitive, lightweight applications.

Use Bonded Fins for high-power, high-volume heat dissipation.

At Kingka Tech, we combine theoretical thermal analysis with practical manufacturing data from over a decade of serving the automotive, medical, and energy sectors. We don't just build to print; we build to perform.

Do not let poor geometry throttle your system's performance.

Contact Kingka Tech today for a comprehensive design review. Let our engineering team help you select the optimal fin geometry and material for your next project.