Views: 430 Author: Site Editor Publish Time: 2025-10-16 Origin: Site

Passive heat sinks dissipate heat using natural convection and thermal conduction without mechanical parts, making them reliable, silent, and energy-efficient for low to moderate heat loads. Active heat sinks, conversely, incorporate fans or blowers to actively disperse heat, offering higher cooling capacity and a more compact design for high-performance, densely packed electronics, albeit with increased noise, cost, and maintenance.

Keeping our electronics cool is crucial for their performance and longevity. Just like our bodies need to regulate temperature, electronic components like CPUs and GPUs generate heat that must be managed to prevent damage and ensure proper functioning. When it comes to cooling solutions, you'll primarily encounter two main types: passive heat sinks and active heat sinks. While both aim to dissipate heat, they achieve this through fundamentally different mechanisms, each with its own set of advantages and disadvantages. Understanding these differences is key to selecting the most effective cooling solution for your specific device, whether it's a quiet home appliance or a powerful gaming PC. Let's dive into a detailed comparison to help you decide which is the best fit for your thermal management needs.

Understanding the core mechanism of a passive heat sink is the first step in appreciating its role in thermal management.

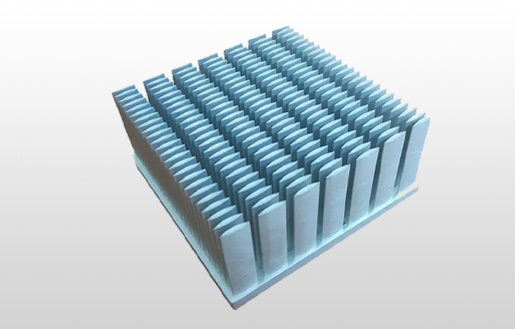

A passive heat sink dissipates heat from electronic components without relying on any mechanical devices or external power sources. Instead, it leverages natural airflow and thermal conduction, transferring heat from a hot component to its large surface area, often enhanced by fins or ridges, and then dispersing it into the surrounding ambient air through natural convection.

The operation of a passive heat sink is elegantly simple and relies on fundamental physics. When an electronic component, such as a CPU, generates heat, this heat is transferred to the base of the heat sink through thermal conduction. The heat then spreads throughout the heat sink's body and fins. As the heat sink warms up, the air immediately surrounding its surfaces also heats up, becoming less dense and rising. Cooler, denser air from the surroundings then moves in to replace the rising warm air, creating a continuous natural airflow, or convection current, that carries heat away from the heat sink and into the ambient environment. The larger the surface area of the heat sink, typically achieved through fins or ridges, the more efficiently this natural convection can occur, allowing for greater heat transfer.

Passive heat sinks offer several compelling benefits that make them ideal for specific applications:

Reliability and Longevity: Since they have no moving parts like fans or pumps, passive heat sinks are inherently more reliable and have a longer lifespan. There's no wear and tear, reducing the risk of mechanical failure.

Silent Operation: The absence of moving components means passive heat sinks operate completely silently. This makes them highly desirable in noise-sensitive environments such as audio equipment, home theaters, or quiet office settings.

Energy Efficiency: Passive heat sinks consume no additional power beyond what the electronic device itself needs. This makes them highly energy-efficient, which is particularly beneficial for battery-powered devices or applications where energy conservation is a priority.

Low Maintenance: With no fans to collect dust or liquid systems to monitor for leaks, passive heat sinks require negligible maintenance. Dust accumulation is less of a concern compared to active systems.

Compact and Simple Design: Passive heat sinks are often simpler in design and can be more compact in certain configurations, making them suitable for applications with space constraints.

These advantages make passive heat sinks a popular choice for devices with moderate heat loads where quiet operation and reliability are paramount.

In contrast to their passive counterparts, active heat sinks take a more forceful approach to cooling.

An active heat sink is a cooling solution that incorporates mechanical devices, typically fans or blowers, to actively move air or liquid over the heat sink's surface, thereby enhancing heat dissipation. This forced airflow or liquid circulation significantly augments cooling efficiency, making active heat sinks ideal for high-performance electronic systems with substantial heat loads.

Active heat sinks operate on the principle of forced convection. While they still rely on thermal conduction to transfer heat from the component to the heat sink, they don't wait for natural airflow to dissipate it. Instead, an external power source drives a fan or blower, which actively pushes or pulls air across the heat sink's fins. This forced airflow dramatically increases the rate of heat transfer from the heat sink to the surrounding air, allowing for much more efficient and rapid cooling. In some advanced active systems, liquid cooling mechanisms are used, where a pump circulates a coolant through a waterblock (a specialized heat sink) and then to a radiator, further enhancing heat removal. This active approach ensures that even densely packed or high-power devices can maintain optimal operating temperatures.

Active heat sinks offer distinct benefits, particularly for demanding applications:

Higher Cooling Capacity: Due to forced airflow or liquid cooling, active heat sinks can dissipate significantly more heat than passive ones. This makes them indispensable for high-performance components like gaming CPUs, powerful GPUs, and server processors that generate substantial heat.

Greater Efficiency in Heat Transfer: The active movement of air or liquid ensures a quicker and more effective transfer of heat away from the electronic components. This increased efficiency is crucial for maintaining stable temperatures under heavy loads.

More Compact Design (for high performance): While they contain moving parts, active heat sinks can often achieve a higher cooling capacity in a smaller footprint compared to a passive heat sink designed for the same heat load. This is fundamental in modern electronics where space is limited, allowing for more powerful devices in a smaller form factor.

Better Performance in High Ambient Temperatures: Unlike passive heat sinks, whose efficiency decreases in high ambient temperatures, active heat sinks can maintain their cooling performance more effectively because they actively force air movement, overcoming the limitations of natural convection.

These advantages make active heat sinks the go-to choice for systems where performance and rapid heat removal are paramount, even if it comes with trade-offs.

To truly understand which cooling solution is best, a direct comparison of passive heat sink and active heat sink characteristics is essential.

Passive heat sinks are generally cheaper, quieter, more reliable, and require less maintenance due to their lack of moving parts, making them suitable for low to moderate heat loads. Active heat sinks, conversely, offer significantly higher cooling capacity and efficiency for high-performance components, but come with increased cost, noise, maintenance, and a shorter lifespan due to their mechanical components.

Let's break down the key factors:

Factor | Active Heat Sinks | Passive Heat Sinks |

Cooling Capacity | Generally higher due to forced air or liquid cooling mechanisms. Can handle more heat from high-performance components. | Lower than active heat sinks since they rely on natural airflow and heat dissipation. Suitable for low to moderate heat-generating components. |

Efficiency | More efficient in heat transfer due to fans, blowers, or liquid cooling systems that increase airflow and heat removal. | Less efficient in rapid heat transfer. Efficiency depends on natural convection and radiation, which can be slower and less predictable. |

Cost | Initially more expensive due to mechanical components. Also, operational costs can be higher due to power consumption. | Generally cheaper because they do not require additional components. Have lower operational costs since they don't consume extra power. |

Space | May require more space for fans, heat pipes, or liquid cooling components. However, can achieve higher performance in a smaller footprint for high heat loads. | Compact and simpler in design, requiring less space. Ideal for applications with space constraints. |

Maintenance | Requires more maintenance. Fans may accumulate dust and need cleaning. Liquid cooling systems need monitoring for leaks. | Negligible maintenance because there are no moving parts. Dust accumulation is less of a concern. |

Lifespan | Shorter life owing to wear and tear of mechanical parts. The risk of failure can affect longevity. | Longer life since there are no parts that wear out. More reliable over a period, thanks to simpler construction. |

Noise | Can be noisy due to fans or pumps. | Silent operation. |

Power Source | Requires an external power source for fans/blowers. | Does not require an external power source. |

This table clearly illustrates the trade-offs involved in choosing between a passive heat sink and an active heat sink, emphasizing that the "better" choice is entirely context-dependent.

The choice of material and the specific design are crucial for both passive heat sink and active heat sink performance, though their priorities can vary.

For both passive and active heat sinks, copper is preferred for its high thermal conductivity in high-heat applications, while aluminum is chosen for its lightweight, cost-effectiveness, and good thermal dissipation in general uses. Passive heat sink designs focus on maximizing surface area for natural convection, whereas active heat sink designs prioritize fan size, placement, and airflow direction to optimize forced convection and heat transfer.

The materials used for heat sinks are primarily copper and aluminum, each selected for specific thermal properties.

Copper: Known for its high thermal conductivity, copper is excellent at rapidly absorbing and dispersing heat. This makes it a preferred material for both passive heat sinks and active heat sinks when dealing with higher thermal loads or when maximum heat dissipation is required in a compact space. However, copper is heavier and generally more expensive than aluminum.

Aluminum: Aluminum offers a lightweight and cost-effective alternative with good thermal conductivity. It is widely used in both types of heat sinks, especially in consumer electronics where weight and cost are significant considerations. For passive heat sinks in general uses, aluminum is a common choice due to its balance of cost-effectiveness and thermal performance.

The physical design of a heat sink is paramount to its effectiveness, and this differs significantly between passive and active types.

Passive Heat Sink Design: The structural design of passive heat sinks focuses on maximizing the surface area exposed to the ambient air to enhance natural convection and radiation. This typically involves intricate arrangements and shapes of fins or ridges. The goal is to create as much contact between the heat sink and the air as possible, allowing the natural rising of warm air and influx of cooler air to carry heat away efficiently. The efficiency of a passive heat sink is also heavily influenced by the ambient temperature, as a smaller temperature gradient between the heat sink and the air reduces the heat transfer rate.

Active Heat Sink Design: For active heat sinks, the design is centered around optimizing the interaction with forced airflow. Key design elements include the size and placement of the fan, and the direction of airflow. Larger fans can move more air for better cooling but require more space and can be noisier. The strategic placement of fans, whether drawing air away or pushing cool air towards the heat sink, directly impacts cooling performance. Additionally, thermal interface materials like thermal pastes or pads are crucial in active systems to ensure efficient heat transfer between the electronic component and the heat sink by filling microscopic imperfections for better contact.

In essence, passive heat sink design is about facilitating natural processes, while active heat sink design is about engineering the most effective forced cooling environment.

The distinct characteristics of passive heat sinks and active heat sinks mean they are best suited for different types of electronic devices and operating environments.

Passive heat sinks are ideal for less power-intensive electronics with moderate heat loads, such as LED lighting systems, low-power computer processors, TVs, kitchen appliances, and audio equipment, where silent operation, reliability, and energy efficiency are prioritized. Active heat sinks, conversely, are essential for high-performance, high-power devices like gaming PCs, servers, aerospace electronics, and gaming laptops, where rapid and efficient heat dissipation is critical despite potential noise and maintenance requirements.

Passive heat sinks are the preferred choice for applications where heat generation is manageable and factors like noise, energy consumption, and long-term reliability without maintenance are crucial.

LED Lighting Systems: LEDs generate heat that needs to be dissipated to maintain their efficiency and lifespan. Passive heat sinks are widely used here due to their silent operation and lack of moving parts, which contribute to the overall longevity of the lighting fixture.

Low-Power Computer Processors: For embedded systems, single-board computers (like Raspberry Pi), or older, less demanding CPUs, a passive heat sink can provide sufficient cooling without the added complexity or noise of a fan.

Consumer Electronics: Many everyday items such as TVs, kitchen appliances, and audio equipment benefit from passive cooling. Their moderate heat loads don't necessitate aggressive cooling, and silent operation is often a key user expectation.

Industrial Automation: In certain industrial control systems where dust or vibration might be an issue for moving parts, a robust passive heat sink can offer reliable cooling.

These applications prioritize quiet, reliable, and energy-efficient operation over maximum cooling capacity.

Active heat sinks are indispensable for environments where electronic components generate significant heat and require rapid, efficient dissipation to maintain performance and prevent thermal throttling.

High-Performance Gaming PCs and Laptops: Modern CPUs and GPUs in gaming systems generate immense heat, especially under load. Active heat sinks with powerful fans are essential to keep these components cool, ensuring stable frame rates and preventing performance degradation.

Servers and Data Centers: Server racks are packed with high-power processors that run 24/7. Active cooling solutions, often incorporating large fans or liquid cooling, are critical for maintaining optimal operating temperatures, ensuring data integrity, and preventing system crashes.

Aerospace Electronics: In aerospace applications, components often operate in confined spaces and under varying thermal conditions. Active heat sinks provide the necessary robust and efficient cooling to ensure the reliability of critical systems.

Workstations and Professional Graphics Cards: Similar to gaming PCs, professional workstations and high-end graphics cards used for rendering, CAD, or scientific computing require aggressive active cooling to handle sustained high workloads.

These applications demand high cooling capacity and efficiency, making active heat sinks the only viable option despite their associated noise and maintenance.

The decision between a passive heat sink and an active heat sink is a critical one that impacts performance, cost, and reliability.

Selecting the right heat sink, whether passive or active, requires comprehensively considering the device's size, power consumption, and expected ambient temperature. Passive heat sinks are ideal for low-heat, quiet, and low-maintenance applications, while active heat sinks are necessary for high-performance, high-heat devices that demand efficient cooling despite potential noise and maintenance.

Here's a breakdown of the factors you should consider:

Heat Load (Power Consumption): This is arguably the most important factor.

Low to Moderate Heat Load: If your electronic component generates minimal to moderate heat (e.g., a low-power microcontroller, LED driver, or a simple embedded system), a passive heat sink is likely sufficient and offers benefits like silence and reliability.

High Heat Load: For components that generate significant heat (e.g., high-end CPUs, GPUs, power amplifiers, or server processors), an active heat sink is almost always necessary to prevent overheating and ensure stable performance.

Space Constraints:

Limited Space, Moderate Heat: A compact passive heat sink might be suitable.

Limited Space, High Heat: An active heat sink might be able to achieve higher cooling in a smaller volume, but the fan itself will take up space.

Noise Requirements:

Silent Operation is Critical: If the device needs to be completely silent (e.g., audio equipment, home theater PCs, medical devices), a passive heat sink is the clear choice.

Noise is Acceptable: For gaming PCs, servers, or industrial equipment where performance is prioritized, the noise from an active heat sink's fan is often an acceptable trade-off.

Cost and Budget:

Budget-Friendly: Passive heat sinks are generally cheaper due to fewer components and no power consumption.

Higher Budget: Active heat sinks have a higher initial cost due to mechanical parts and can have higher operational costs due to power consumption.

Maintenance and Lifespan:

Low Maintenance, Long Lifespan: Passive heat sinks require negligible maintenance and have a longer lifespan due to no moving parts.

Regular Maintenance, Shorter Lifespan: Active heat sinks require more maintenance (e.g., dust cleaning, monitoring liquid systems) and have a shorter lifespan due to wear and tear on mechanical components.

Ambient Temperature:

Stable, Moderate Ambient Temperature: Passive heat sinks perform well.

High or Fluctuating Ambient Temperature: Active heat sinks are more effective as they can overcome the limitations of natural convection.

Ultimately, the choice of heat sink depends on the specific needs of your equipment. If you're unsure, consulting a thermal management expert is an excellent way to find an effective cooling solution for your needs.

The world of thermal management offers diverse solutions, with passive heat sinks and active heat sinks standing as the two primary approaches. Neither is inherently "better" than the other; instead, their effectiveness is entirely dependent on the specific demands of the electronic device and its operating environment.

In conclusion, passive heat sinks excel in applications requiring silence, reliability, and energy efficiency for low to moderate heat loads, leveraging natural convection. Active heat sinks, conversely, provide superior cooling capacity and efficiency for high-performance, high-heat-generating components through forced airflow, albeit with increased noise, cost, and maintenance. The optimal choice hinges on a careful evaluation of heat load, space, noise, cost, and maintenance requirements.

For those seeking quiet, reliable, and energy-efficient cooling for less demanding electronics, the passive heat sink is an excellent choice, offering a robust solution with minimal fuss. However, when raw power and maximum heat dissipation are non-negotiable, active heat sinks step up to the challenge, ensuring that high-performance systems can operate at their peak without succumbing to thermal stress.

Are you grappling with thermal challenges in your electronic designs? Don't let overheating compromise your product's performance or lifespan. KingKa Tech specializes in providing customized thermal solutions, including both passive and active heat sinks, liquid cold plates, and precision CNC machining services. With over 15 years of experience, our expert team can help you analyze your specific needs and design the perfect cooling solution. Contact us today for a consultation and ensure your electronics stay cool and perform optimally!