Views: 16 Author: Site Editor Publish Time: 2023-08-22 Origin: Site

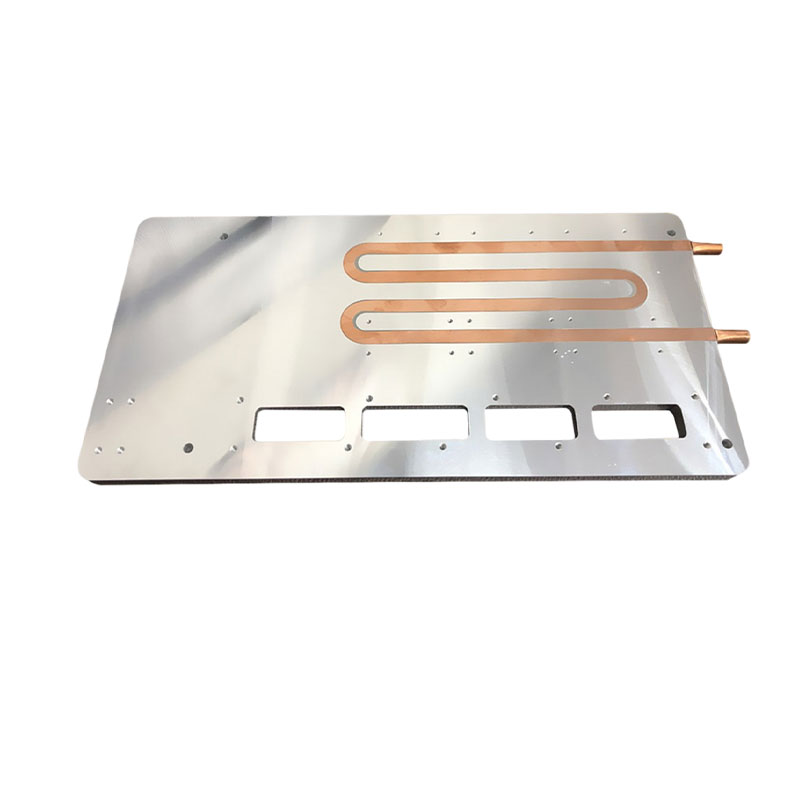

Welcome back to our blog! Today, we are diving into the fascinating world of welding and exploring a specific welding technique known as friction stir welding (FSW) and its application in liquid cold plates. If you are curious about the structural integrity of friction stir welded liquid cold dishes and how it stacks up against other welding methods, you've come to the right place. In this blog post, we will provide a comprehensive comparison, highlighting the benefits and advantages of FSW. So, let's buckle up and get started!

Friction stir welding (FSW) is a solid-state joining process that enables the creation of high-quality, defect-free welds in various materials. Unlike traditional welding methods, FSW doesn't involve melting the workpieces. Instead, it uses a rotating tool to generate frictional heat between the workpieces, softening the material and allowing for a solid-state bond to be formed.

The FSW process was first developed in the early 1990s by The Welding Institute (TWI) and has since gained popularity due to its numerous advantages over conventional welding methods. It has mainly found its niche in industries where superior strength, enhanced structural integrity, and excellent heat dissipation are crucial, such as manufacturing liquid cold plates.

One of the critical advantages of friction stir welding in liquid cold plate manufacturing is its exceptional joint strength. FSW creates a robust and uniform bond between the materials, resulting in welds that exhibit superior tensile, shear, and fatigue strength. This is particularly important for liquid cold plates as they often need to withstand high pressures and mechanical stresses while ensuring the efficient transfer of heat.

Compared to traditional welding methods like TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, friction stir welding produces welds with minimal defects such as porosity, cracks, or voids, which can significantly compromise the structural integrity of the liquid cold plate. With FSW, manufacturers can achieve consistently solid and reliable joints, ultimately enhancing the overall durability and performance of the liquid cold plates.

Effective heat dissipation is a critical requirement for liquid cold plates, primarily used for thermal management applications. Traditional welding methods often introduce heat-affected zones (HAZ) and residual stresses, which can impede the heat transfer capabilities of the plate. On the other hand, friction stir welding minimizes HAZ and preserves the base material's microstructure, enabling efficient heat conduction across the plate.

The unique stirring action of the FSW tool creates a refined, equiaxed grain structure within the weld zone, improving the thermal conductivity of the joint. As a result, friction stir welded liquid cold plates can efficiently dissipate high heat loads, making them ideal for demanding thermal management applications.

Welding-induced distortion and warping can be a significant concern, particularly when manufacturing complex-shaped liquid cold plates. The localized heating and cooling cycles associated with traditional welding methods often lead to dimensional inaccuracies and shape deformations, compromising the precision and functionality of the cold plate.

Friction stir welding, being a solid-state joining process, significantly reduces the occurrence of distortion and warping. By avoiding the melting and subsequent solidification stages, FSW minimizes thermal deformation and produces welds with excellent dimensional stability. Manufacturers can achieve precise and accurate liquid cold plates, ensuring a seamless fit and optimal performance in various heat exchanger applications.

TIG (Tungsten Inert Gas) welding, also known as GTAW (Gas Tungsten Arc Welding), is a commonly used welding technique in various industries. While TIG welding offers versatility, it needs to improve joint strength and heat dissipation compared to friction stir welding.

TIG welding relies on applying a concentrated electric arc to melt and fuse the workpieces, which can result in HAZ, porosity, and other defects. In contrast, friction stir welding retains the material's integrity, resulting in firmer, defect-free welds with improved heat conductivity.

Additionally, TIG welding often requires filler material, which can introduce inhomogeneity and reduce the overall strength of the joint. Friction stir welding, a solid-state process, eliminates the need for filler material, ensuring a more homogeneous and robust bond.

MIG (Metal Inert Gas) welding, also known as GMAW (Gas Metal Arc Welding), is another popular welding method utilized in various industries. However, MIG welding may present certain limitations regarding liquid cold plate manufacturing.

MIG welding involves the formation of an arc between a consumable electrode and the workpieces, leading to extensive heat input and potential distortions. This can be problematic for liquid cold plates, where dimensional accuracy is vital. With its low heat input and reduced distortion, friction stir welding offers a more suitable solution for manufacturing intricate cold plate designs.

Additionally, MIG welding often requires post-weld finishing operations like grinding and smoothing to achieve an aesthetic appearance. On the other hand, friction stir welding produces visually appealing welds without the need for extensive post-processing, contributing to time and cost savings.

In conclusion, friction stir welding (FSW) stands out as a superior welding method for manufacturing liquid cold plates when compared to traditional techniques like TIG and MIG welding. The structural integrity of friction stir welded liquid cold plates surpasses that of their counterparts in terms of joint strength, heat dissipation, and dimensional accuracy.

Manufacturers can ensure high-quality, defect-free welds, enhance heat transfer capabilities, and minimize distortion and warping by opting for friction stir welding. These advantages make friction stir welded liquid cold plates ideal for demanding thermal management applications in various industries.

So, if you are in the market for liquid cold plates with exceptional structural integrity, consider friction stir welding for your customizations. Trust the power of FSW to deliver top-quality, reliable, and efficient liquid cold dishes that exceed your expectations.

If you want to delve deeper into friction stir welding or need assistance with your specific requirements, don't hesitate to contact our team of experts. We are here to offer our expertise and help you make informed decisions. Stay tuned for more exciting content and happy welding!