Views: 5 Author: Site Editor Publish Time: 2025-12-17 Origin: Site

Assembled liquid cold plates are advanced thermal management devices that efficiently remove heat from high-performance electronics by circulating coolant through precisely constructed internal channels, offering superior heat transfer and temperature control compared to air cooling. They are custom-tailored to specific applications, optimizing thermal performance and integrating seamlessly into larger systems.

In high-performance electronics across various industries—from telecommunications and data centers to automotive and medical devices—maintaining precise temperature control is paramount for system longevity and smooth operation. While many types of liquid cold plates exist, the "assembled" category represents a versatile and often highly customized approach to managing intense thermal loads. This guide will delve into what makes assembled liquid cold plates a favored solution, focusing on their construction, benefits, and applications.

Why Choose Assembled Liquid Cold Plates for Thermal Management?

What are the Performance Advantages of Assembled Liquid Cold Plates?

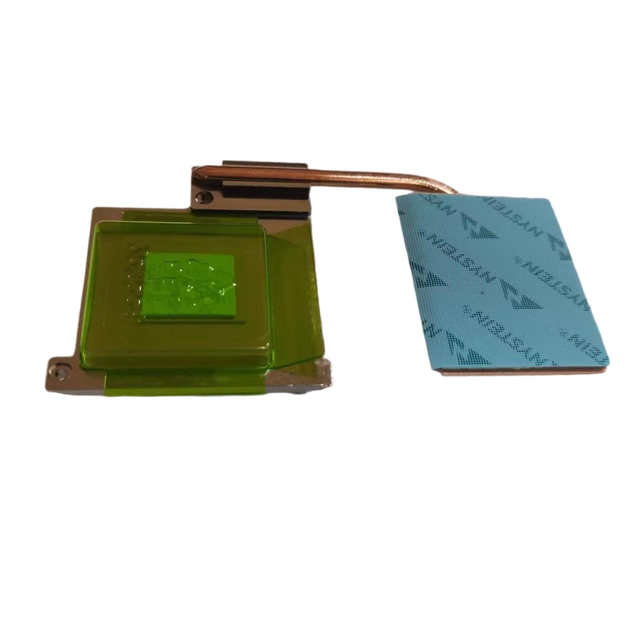

An assembled liquid cold plate is a cooling device constructed by joining multiple components, such as a base plate, cover, and internal fin structures or tubes, to create sealed pathways for circulating coolant, which then absorbs and transfers heat away from electronic components. This closed-loop system ensures efficient temperature control, especially where air cooling is insufficient.

The term "assembled" highlights a manufacturing approach where different parts are brought together and bonded, often through processes like vacuum brazing, friction stir welding, or tube embedding, to form the final cold plate structure. This allows for complex internal geometries and the integration of various materials.

The core components of an assembled liquid cold plate typically include a base plate that contacts the heat source, a cover plate, and internal structures like fins, turbulators, or embedded tubes that define the coolant flow paths.

Examples: In a vacuum brazed cold plate, the base and cover might encapsulate a corrugated fin structure. For a tube-embedded design, copper or stainless steel tubes are pressed or soldered into grooves in the base plate, then sealed with a cover.

Key Takeaway: The modular nature of assembled cold plates allows for highly customized internal designs to optimize fluid flow and heat transfer efficiency.

Core Components:

Base Plate: Contacts the heat-generating component.

Cover Plate: Seals the coolant channels.

Internal Structures: Fins, turbulators, or embedded tubes for fluid flow.

An assembled cold plate functions by absorbing heat from the component through its base plate, transferring that heat to the circulating coolant within its internal channels, and then carrying the heated coolant away to a remote heat exchanger for dissipation.

Examples: Heat from an IGBT module conducts into the cold plate's base. The coolant (e.g., water-glycol mixture) flows through the channels, picks up this heat, and is pumped to a radiator where the heat is released to the ambient air.

Key Takeaway: The active circulation of a high-heat-capacity liquid is what makes assembled cold plates exceptionally effective at localized heat removal.

Functional Steps:

Heat Absorption: Base plate draws heat from the source.

Heat Transfer to Coolant: Coolant absorbs heat via forced convection.

Coolant Circulation: Heated coolant is pumped away for remote dissipation.

Assembled liquid cold plates are chosen for thermal management due to their superior thermal conductivity, compact design, ability to extend component lifespan, and capacity to provide stable performance, especially in high-power applications where air cooling is insufficient.

These advantages make them indispensable for industries relying on high-powered electronic systems that demand precise and efficient cooling.

Assembled cold plates offer significant thermal advantages, primarily due to liquids having a much higher heat capacity than air, allowing for more effective and rapid heat transfer from high-power components.

Examples: In a data center server, an assembled cold plate can directly cool a CPU, preventing overheating that would otherwise degrade performance. For EV battery packs, they maintain optimal operating temperatures, crucial for battery longevity and safety.

Key Takeaway: The use of liquid as a heat transfer medium fundamentally outperforms air in terms of thermal efficiency, especially for concentrated heat sources.

Thermal Advantages:

Superior Heat Capacity: Liquids absorb more heat per unit volume than air.

Effective Heat Transfer: Enables rapid heat removal from high-power applications.

Localized Cooling: Targets specific hot spots with high precision.

Assembled cold plates impact system design by allowing for more compact and lightweight solutions, eliminating the need for bulky fans or ductwork, and significantly improve reliability and safety by preventing overheating and extending component lifespan.

Examples: Their compact nature allows for denser component packing in telecommunications equipment. By maintaining lower, stable temperatures, they reduce the risk of component failure in medical devices, enhancing patient safety.

Key Takeaway: Beyond just cooling, assembled cold plates contribute to overall system miniaturization, robustness, and long-term operational integrity.

Design & Reliability Impacts:

Compact Design: No bulky fans or ductwork needed.

Extended Component Lifespan: Prevents overheating degradation.

Improved Reliability & Safety: Reduces risk of component failure.

Assembled liquid cold plates are constructed using advanced manufacturing processes such as tunnel and vacuum brazing, friction stir welding, or tube embedding, which ensure tight, reliable bonds between components and create robust, leak-proof internal channels for coolant flow.

These high-precision techniques are essential for achieving the exact specifications and structural integrity required for effective thermal performance.

Friction Stir Welded (FSW) cold plate construction involves using a rotating tool to generate frictional heat, softening the metal and creating a strong, solid-state bond without melting the material, resulting in robust and durable plates.

Examples: FSW is ideal for joining aluminum plates to create complex internal channel designs for large-scale, high-powered applications like EV battery cooling, where structural integrity is paramount.

Key Takeaway: FSW offers excellent structural integrity and is particularly suited for lightweight materials like aluminum, making it a strong choice for demanding applications.

FSW Construction Features:

Solid-State Bonding: No melting of metal, strong joints.

Robust & Durable: Ideal for high-stress applications.

Material Versatility: Commonly used for aluminum.

Vacuum brazed cold plate construction involves heating materials in a vacuum chamber with a filler metal, which melts and flows into the joints by capillary action, creating a clean, high-strength, and hermetically sealed bond.

Examples: This technique is highly efficient for precise heat transfer and is commonly used in electronics and medical devices where clean, void-free joints are critical for reliability.

Key Takeaway: Vacuum brazing produces exceptionally clean and strong joints, making it suitable for applications requiring high efficiency and stringent cleanliness.

Vacuum Brazed Construction Features:

High-Strength Joints: Creates robust, reliable bonds.

Clean Process: Vacuum environment prevents oxidation.

Hermetic Sealing: Ensures leak-proof coolant channels.

Tube embedded cold plate construction involves embedding tubes (typically copper or stainless steel) within grooves machined into a base plate, which are then sealed with a cover plate, creating a pathway for the coolant.

Examples: This method is a simple, cost-effective solution widely used in industrial applications where a straightforward and reliable cooling path is needed.

Key Takeaway: Tube embedding offers a versatile and often more economical approach for creating coolant channels, particularly for less complex designs.

Tube Embedded Construction Features:

Embedded Tubes: Copper or stainless steel tubes form channels.

Simple & Cost-Effective: Widely used in industrial settings.

Versatile Design: Allows for various channel layouts.

Assembled liquid cold plates offer enhanced cooling efficiency, custom fit for specific applications, cost-effectiveness in the long run, and improved reliability and safety, making them superior to air cooling for managing high thermal loads.

These advantages collectively contribute to the optimal performance and longevity of the electronic systems they cool.

Assembled cold plates achieve enhanced cooling efficiency through the superior thermal properties of liquids compared to air, their direct contact with heat sources, and optimized internal channel designs that maximize heat transfer to the circulating coolant.

Examples: A custom-designed internal fin structure within an assembled cold plate can create turbulence in the coolant, further increasing heat transfer from the plate material to the liquid.

Key Takeaway: The combination of a high-performance coolant and intelligently designed internal geometries allows assembled cold plates to dissipate heat far more effectively than air-based solutions.

Efficiency Drivers:

Liquid Thermal Properties: High heat capacity and conductivity.

Direct Contact: Maximizes heat absorption from the source.

Optimized Channel Design: Enhances forced convection within the plate.

The long-term benefits of assembled cold plates include reduced maintenance costs, extended lifespan of protected components, and improved system reliability and safety by preventing overheating and component failure.

Examples: While initial costs might be higher, the ability of an assembled cold plate to keep sensitive components like power semiconductors at optimal temperatures prevents premature failure, saving significant replacement and downtime costs over years of operation.

Key Takeaway: Investing in assembled liquid cold plates yields substantial returns through prolonged equipment life and more stable, reliable operation.

Long-Term Benefits:

Reduced Maintenance: Fewer component failures due to overheating.

Extended Lifespan: Components operate within safe temperature limits.

Improved Reliability: Consistent performance, reduced risk of failure.

Assembled liquid cold plates are typically used in industries that rely on high-powered electronic systems and require precise thermal management, including data centers, automotive, aerospace, medical devices, and consumer electronics.

Their ability to handle high heat flux in compact designs makes them indispensable for these demanding applications.

In high-performance computing, assembled liquid cold plates are used for direct-to-chip cooling of CPUs, GPUs, and other high-density components in data centers and supercomputers, where heat loads are immense and stable operating temperatures are critical for performance and reliability.

Examples: Cooling server racks in data centers to prevent thermal throttling and improve energy efficiency. Maintaining optimal temperatures for powerful processors in AI and machine learning clusters.

Key Takeaway: Assembled cold plates are vital for sustaining the intense computational demands of modern data centers and advanced computing.

HPC Applications:

CPU/GPU Cooling: Direct-to-chip thermal management.

Data Centers: Preventing thermal throttling, improving efficiency.

Supercomputers: Maintaining stable temperatures for high-density components.

In electric vehicles, assembled cold plates are utilized for cooling battery packs, power inverters, and motor controllers, ensuring optimal operating temperatures for extended battery life, faster charging, enhanced performance, and critical safety.

Examples: An FSW assembled cold plate might be integrated directly into an EV battery module to maintain uniform cell temperatures. A vacuum brazed cold plate could cool the high-power IGBTs in the vehicle's inverter.

Key Takeaway: Assembled cold plates are fundamental to the performance, longevity, and safety of electric vehicle powertrains.

EV Applications:

Battery Pack Cooling: Ensures optimal temperature for life and performance.

Power Inverters: Dissipates heat from high-power electronics.

Motor Controllers: Maintains stable temperatures for efficient operation.

Kingka specializes in assembled liquid cold plates by offering a wide range of customized solutions, including copper/stainless steel tube, FSW, deep drilled, and vacuum brazed cold plates, backed by over 15 years of expertise in thermal management and precision manufacturing. We are committed to being a one-stop thermal solution provider, meeting diverse client needs.

Our strong technical R&D team, equipped with advanced CNC machines and testing equipment, ensures high-quality production and adherence to strict industry standards.

Kingka offers comprehensive manufacturing capabilities for assembled cold plates, including CNC milling, turning, friction stir welding, vacuum brazing, and tube embedding, allowing for the production of various complex designs and materials.

Examples: We can produce custom FSW liquid cold plates for lightweight EV applications or precision deep-drilled cold plates for high-density semiconductor equipment. Our facilities are equipped with 35 sets of high-end CNC machines.

Key Takeaway: Kingka's diverse manufacturing processes and advanced equipment enable the creation of highly customized and high-performance assembled cold plates.

Kingka's Manufacturing Capabilities:

FSW (Friction Stir Welding): For robust, lightweight aluminum plates.

Vacuum Brazing: For clean, high-strength, hermetically sealed joints.

Tube Embedding: For versatile and cost-effective designs.

Kingka ensures quality and customization for assembled cold plates through a dedicated technical R&D team providing free design support and thermal analysis, coupled with rigorous inspection processes and adherence to high industry standards.

Examples: Our R&D team, with over 25 years of experience in mechanical and thermal fields, offers thermal design and airflow simulation to optimize cold plate performance. All products undergo at least four strict inspections using advanced testing equipment like CMMs and projectors.

Key Takeaway: Kingka's commitment to expert design, advanced testing, and stringent quality control guarantees reliable and precisely customized assembled liquid cold plates.

Kingka's Quality & Customization:

Expert R&D Team: Provides free technical design and simulation.

Rigorous Inspection: At least four strict inspections per product.

Advanced Testing Equipment: Utilizes CMM, projectors, etc., for precision.

Assembled liquid cold plates represent a pinnacle in thermal management technology, offering unparalleled efficiency and precision for high-power electronic systems. Their ability to leverage the superior thermal properties of liquids, combined with advanced manufacturing techniques like FSW, vacuum brazing, and tube embedding, allows for highly customized solutions that significantly enhance cooling efficiency, extend component lifespan, and improve overall system reliability and safety. For industries ranging from electric vehicles to data centers, these custom-tailored cooling devices are not just an advantage but a necessity. Kingka, with its extensive expertise and comprehensive manufacturing capabilities, stands as a leading provider of high-quality assembled liquid cold plates, ready to meet the most demanding thermal challenges with innovative and reliable solutions.