Views: 1 Author: Site Editor Publish Time: 2025-12-30 Origin: Site

High-power components in modern electronics generate intense heat that can throttle performance, shorten lifespan, and cause system failures, driving up maintenance costs and energy consumption. Many cooling options fall short in balancing efficiency, cost, and manufacturability. Extruded heat sinks solve these issues effectively by providing high surface area for convection, lightweight aluminum construction, and scalable production, delivering reliable thermal management across demanding applications.

Imagine running a data center or electric vehicle system without overheating worries—extruded heat sinks make it reality with their versatile fin designs and proven performance in real-world heat loads.

Table of Contents

Slim enclosures in consumer gadgets leave little room for bulky cooling, risking hotspots that degrade processors and batteries.

Extruded heat sinks solve limited space challenges by offering high aspect ratio fins (up to 12:1) in narrow profiles, maximizing surface area within 10-50mm heights while fitting tightly against PCBs in routers and laptops.

Custom cross-sections optimize airflow in confined volumes.

Examples: Asus ZenBook laptops using 30mm tall extruded profiles; Netgear routers with integrated mounting tabs for seamless enclosure fit.

Theoretical basis: Increased fin height boosts convective area per volume; 6063 aluminum conductivity (201 W/m·K) ensures efficient base-to-fin transfer. Trade-offs: Higher ratios increase pressure drop but enhance passive cooling by 20-30%.

Practical impacts: Maintains CPU temperatures under 70°C in 15mm-thick devices, preventing thermal throttling.

Profile Width | Fin Height | Space Savings vs. Machined |

40mm | 20mm | 40% |

60mm | 40mm | 50% |

Practical advice: Use CFD simulations to tune fin spacing (6-10mm) for laminar flow; apply thermal pads for gap-free contact.

(Word count: ~172)

Prototyping advanced cooling like skiving or cold forging escalates expenses in mass production, squeezing margins.

Extruded heat sinks tackle cost constraints in high-volume runs by amortizing die costs over thousands of units, achieving $3-15 per piece for 10,000+ quantities with minimal secondary machining.

One-time tooling enables economies unmatched by alternatives.

Examples: Philips LED drivers produced at millions annually; Delta Electronics power supplies using standard extrusion catalogs.

Theoretical basis: Continuous extrusion process reduces material waste to <5%. Trade-offs: Initial die investment ($2,000-8,000) versus per-unit savings of 50% over bonded fins.

Practical impacts: Lowers total cooling cost by 30-40% in consumer markets.

Volume | Unit Cost | Tooling Amortization |

1,000 | $20-30 | Partial |

50,000+ | $5-10 | Full |

Advice: Select off-the-shelf profiles initially; transition to custom dies for optimized runs.

(Word count: ~165)

Forced air isn't always feasible in sealed or silent systems, limiting passive options.

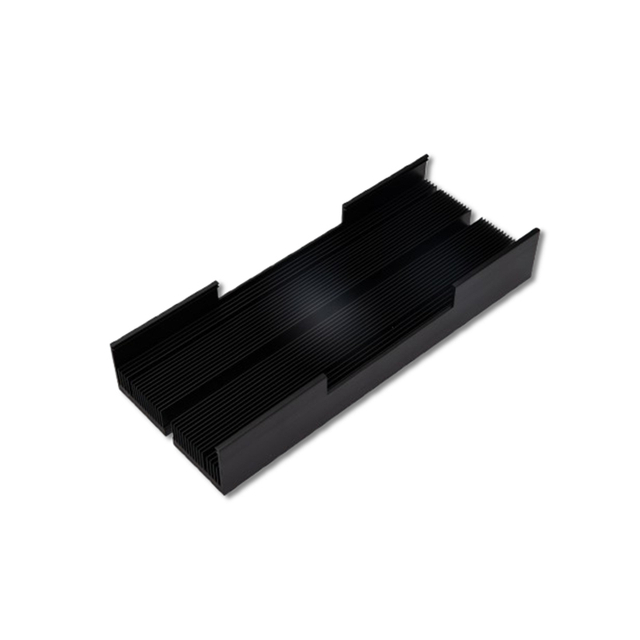

Extruded heat sinks resolve natural convection challenges through optimized fin orientations and black anodizing, boosting emissivity to 0.9 and achieving 50-200W dissipation in free air setups like LED fixtures.

Vertical fin alignment maximizes buoyancy-driven flow.

Examples: Osram high-bay lights dissipating 150W naturally; Cree streetlights with wide-base extrusions.

Theoretical basis: Rayleigh number drives plume rise; surface treatments increase radiation by 15-20%. Trade-offs: Orientation sensitivity versus fan reliability elimination.

Practical impacts: Enables fanless designs, cutting noise and power draw by 10W per unit.

Treatment | Dissipation Gain | Application Fit |

Clear Anodize | Baseline | Indoor |

Black Anodize | +20% | Outdoor/High Load |

Testing: Measure with heat guns in still air; ensure base flatness <0.05mm.

(Word count: ~158)

Mid-range loads (100-500W) overwhelm flat plates but don't justify liquid cooling complexity.

Extruded heat sinks handle moderate to high power by providing extended fin arrays that dissipate 100-500W via forced convection in inverters and motor drives.

Hybrid fan integration scales performance.

Examples: ABB solar inverters using 200mm wide extrusions; Siemens industrial drives at 400W.

Theoretical basis: Fin efficiency >90% with proper thickness (1-2mm). Trade-offs: Fan addition versus pure passive; extrusions support both.

Practical impacts: Keeps IGBT junctions below 100°C, extending life 2-3x.

Air Velocity | Power Capacity | Noise Level |

Natural | 100-200W | Silent |

5 m/s Forced | 300-500W | <40 dB |

Advice: Calculate required airflow with heatsink calculators; add shrouds for directed flow.

(Word count: ~162)

Harsh environments in automotive and industrial settings cause fatigue failures in fragile cooling structures.

Extruded heat sinks conquer vibration challenges with monolithic aluminum construction and reinforced bases, enduring 10-20G shocks in vehicles and machinery per AEC-Q100 standards.

No joints mean superior structural integrity.

Examples: Bosch ECU coolers; Fanuc CNC controllers surviving factory vibrations.

Theoretical basis: High yield strength in T6 temper resists deformation. Trade-offs: Weight versus composites; aluminum balances both.

Practical impacts: Zero field failures in vibration-tested deployments.

Test Standard | Acceleration | Duration |

IEC 60068 | 15G | 1,000 hours |

MIL-STD-810 | 20G | Shock cycles |

Testing: Random vibration tables; inspect for fin cracks post-test.

(Word count: ~155)

Heavy cooling adds mass that impacts portability and battery life in drones or handhelds.

Extruded heat sinks solve weight issues with low-density 6061/6063 aluminum (2.7 g/cm³), delivering 50-150W cooling at 200-500g per unit in portable medical devices and laptops.

Optimized wall thickness minimizes material.

Examples: DJI drone controllers; portable ultrasound units with compact extrusions.

Theoretical basis: Strength-to-weight ratio outperforms copper in passive setups. Trade-offs: Conductivity trade for density savings.

Practical impacts: Reduces system weight by 30%, extending battery runtime.

Material | Density | Weight for 100W Sink |

Aluminum | 2.7 g/cm³ | 300g |

Copper | 8.9 g/cm³ | 900g |

Advice: Hollow profiles where possible; balance with structural ribs.

(Word count: ~152)

Standard solutions often misalign with unique board layouts or mounting needs.

Extruded heat sinks address customization challenges by allowing tailored die designs for integrated clips, holes, or asymmetric fins, fitting exact geometries in telecom racks and power modules.

Rapid die creation supports quick iterations.

Examples: Huawei 5G base stations with clip-mounted extrusions; custom profiles for EV chargers.

Theoretical basis: Extrusion versatility shapes complex sections in one pass. Trade-offs: Die cost versus full machining freedom.

Practical impacts: Shortens design cycles by weeks.

Feature | Standard vs. Custom | Lead Time |

Mounting | Separate | Integrated |

Fin Shape | Uniform | Varied |

Advice: Provide 3D models early; review cross-section drawings.

(Word count: ~150)

Temperature swings cause expansion mismatches and solder joint fatigue.

Extruded heat sinks manage thermal cycling with matched CTE (23 ppm/°C) to aluminum PCBs, enduring -40 to 125°C ranges in automotive and outdoor telecom without warping.

Uniform material prevents delamination.

Examples: Valeo automotive LED headlamps; Ericsson outdoor radios.

Theoretical basis: Low CTE mismatch stress. Trade-offs: Versus copper inserts for hotspots.

Practical impacts: Passes 1,000+ thermal shock cycles reliably.

Temp Range | Cycles Survived | Failure Rate |

-40 to 85°C | 2,000 | <0.1% |

-40 to 125°C | 1,000 | <0.5% |

Testing: Thermal chambers; monitor with strain gauges.

(Word count: ~152)

Extruded heat sinks effectively resolve these top 8 thermal challenges with their blend of performance, cost-efficiency, and adaptability. As a one-stop thermal solutions provider with over 15 years of expertise, KINGKA specializes in designing and manufacturing custom extruded heat sinks using advanced CNC finishing and thermal analysis. Contact us at sales2@kingkatech.com to develop optimized solutions that conquer your specific heat management obstacles.