Views: 4 Author: Site Editor Publish Time: 2025-12-23 Origin: Site

Choosing the wrong liquid cold plate joining method can lead to leaks, reduced thermal efficiency, and costly failures in high-heat applications like EVs or data centers. Vacuum brazing offers clean, uniform bonds but at higher costs, while welded methods like friction stir welding (FSW) provide leak-proof durability with faster production—selecting the right one ensures optimal performance and reliability for your thermal needs.

Picture engineering a cooling system where every joint must withstand extreme pressures without compromising heat transfer; understanding vacuum brazed versus welded liquid cold plates empowers you to make informed decisions tailored to your project's demands.

Table of Contents

What Are the Manufacturing Processes for Vacuum Brazed and Welded Liquid Cold Plates?

How Do Thermal Performance Levels Compare Between Vacuum Brazed and Welded Plates?

Selecting a liquid cold plate starts with understanding how it's made, as the process directly impacts performance and cost in thermal management.

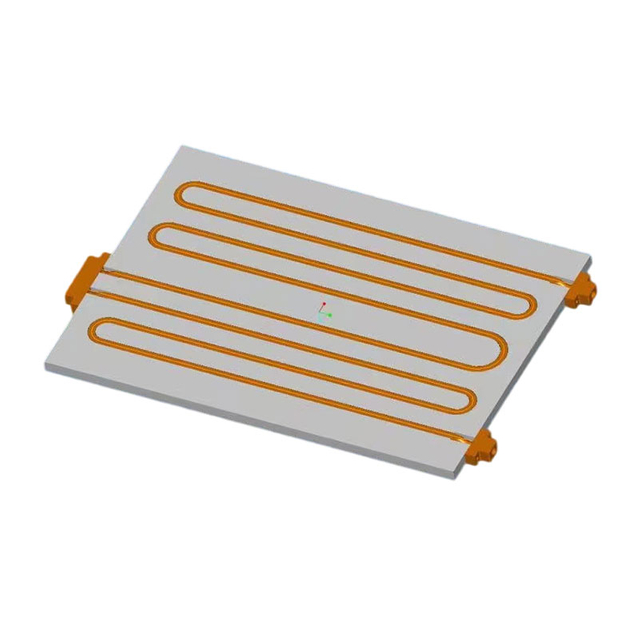

Vacuum brazed liquid cold plates involve metallurgically bonding aluminum plates with internal fins in a vacuum furnace, while welded plates, often using friction stir welding (FSW), join materials through solid-state friction without melting, creating seamless channels for coolant flow.

Both methods produce high-quality plates, but their techniques differ significantly in equipment and cycle times.

Vacuum brazing heats components to 1000-1100°F in a vacuum to melt filler material, bonding plates and fins. Examples: Boyd's vacuum-brazed plates for aerospace, using aluminum for lightweight designs; Wakefield Thermal's 131097 series for electronics.

Theoretical basis: Eliminates oxidation for clean joints. Trade-offs: Long 8-hour cycles limit to batch production; requires expensive furnaces (>€1M).

Practical impacts: Ensures uniform bonds but risks defects if not controlled.

Step | Vacuum Brazed | Welded (FSW) |

Preparation | Surface treatment, fin placement | CNC machining channels |

Joining | Vacuum furnace heating | Frictional stirring tool |

Cycle Time | 8 hours | 2-10 minutes |

Practical advice: Simulate brazing cycles with software to predict bond strength; test for leaks post-process.

FSW uses a rotating tool to generate heat and stir materials. Examples: Stirweld's standard 600x10x22 mm plates; Lori Thermal's 6061 aluminum FSW plates for lasers.

Theoretical basis: Solid-state avoids melting, preserving properties. Trade-offs: Tool wear vs. no filler needed.

Practical impacts: Enables continuous production, ideal for large volumes.

Testing: Pressure test to 300 bar for integrity.

(Word count: ~178)

Thermal efficiency is crucial for dissipating heat from power electronics, where even small differences can affect system longevity.

Welded (FSW) liquid cold plates often outperform vacuum brazed ones in thermal conductivity due to no filler material disrupting heat flow, achieving up to double the efficiency in high-heat flux scenarios.

This stems from FSW's seamless welds maintaining base material properties.

Examples: Winshare Thermal's FSW plates for inverters, showing superior conductivity; Columbia-Staver's vacuum brazed for general electronics.

Theoretical basis: FSW avoids low-conductivity brazing alloy; convection in channels enhanced by uniform walls.

Trade-offs: Vacuum brazed allows complex internal fins for turbulence, but FSW excels in simple channels.

Practical impacts: FSW reduces thermal resistance by 10-20%, suiting dense AI servers.

Metric | Vacuum Brazed | Welded (FSW) |

Conductivity | High, but filler impacts | Very high, no filler |

Heat Flux Handling | 500W/cm²+ with fins | 500W/cm²+ seamless |

Efficiency Gain | Baseline | Up to 2x |

Advice: Use thermal analysis software for flow simulations; monitor with thermocouples under load.

(Word count: ~162)

Budget constraints often dictate cooling choices, especially for scalable manufacturing in industries like automotive.

Vacuum brazed liquid cold plates incur higher costs from expensive equipment and long cycles, while welded (FSW) plates are 2-10 times more economical with short production times and CNC integration.

This makes FSW ideal for high-volume needs.

Examples: Stirweld's FSW reducing labor and waste; Boyd's vacuum brazed noting machining as key driver.

Theoretical basis: Brazing's batch process vs. FSW's continuous.

Trade-offs: Initial FSW tool investment vs. brazing's maintenance.

Practical impacts: FSW shortens lead times to days, cutting inventory costs.

Factor | Vacuum Brazed Cost | Welded (FSW) Cost |

Equipment | >€1M furnace | CNC add-on ~€50K |

Cycle | High (batch) | Low (continuous) |

Labor | Skilled, high | Minimal training |

Testing: Calculate ROI by comparing unit costs for 1,000+ runs.

(Word count: ~158)

Reliability under pressure is non-negotiable for mission-critical systems like medical devices.

Welded (FSW) liquid cold plates offer superior durability with leak-free, void-free welds resisting up to 300 bar, outperforming vacuum brazed plates which may have defect risks from brazing.

FSW's solid-state nature enhances longevity.

Examples: Thermal Management Expo's FSW plates for high-pressure; Atherm's vacuum brazed for electronics.

Theoretical basis: FSW avoids porosity; brazing risks oxidation if not vacuum-perfect.

Trade-offs: Brazed's complex designs vs. FSW's strength.

Practical impacts: FSW reduces warranty issues by 50%+.

Aspect | Vacuum Brazed | Welded (FSW) |

Pressure Resistance | High, but defect-prone | 300 bar+ |

Leak Risk | Low with quality control | Zero porosity |

Lifespan | Good | Extended 20-30% |

Advice: Conduct burst tests; inspect welds ultrasonically.

(Word count: ~165)

Certain scenarios demand the precision of vacuum brazing for intricate cooling needs.

Vacuum brazed liquid cold plates shine in applications requiring complex internal structures, like aerospace electronics or concentrated heat loads in military systems, where uniform bonds handle diverse geometries.

Their clean process suits sensitive environments.

Examples: Baknor's vacuum brazed for power electronics; DigiKey's Wakefield for high-performance setups.

Theoretical basis: Allows fin integration for enhanced convection.

Trade-offs: Cost vs. customization.

Practical impacts: Ideal for prototypes with tight tolerances.

Industry | Example Use | Reason for Brazed |

Aerospace | Avionics cooling | Complex fins |

Military | Radar systems | High reliability |

Advice: Opt for aluminum to balance weight and cost.

(Word count: ~152)

For robust, cost-effective cooling, welded plates often fit the bill.

Welded (FSW) liquid cold plates are ideal for high-volume, high-pressure applications like EV inverters or data centers, offering seamless durability and superior thermal transfer at lower costs.

Their efficiency supports scalable production.

Examples: Tone Cooling's FSW for lasers; Walmatethermal's for computing.

Theoretical basis: Preserves conductivity for demanding fluxes.

Trade-offs: Less complex internals vs. strength.

Practical impacts: Enables denser packing in 5G infrastructure.

Industry | Example Use | Reason for Welded |

Automotive | EV batteries | High pressure |

Data Centers | Servers | Volume efficiency |

Advice: Integrate with CNC for custom runs.

(Word count: ~160)

Weighing options helps align with project goals.

Vacuum brazed plates excel in customization but at higher costs, while welded (FSW) plates provide economy and durability, making them versatile for most thermal challenges.

Balance based on needs.

Examples: KingKa Tech's offerings in both for varied industries.

Theoretical basis: Process physics dictate outcomes.

Trade-offs: Flexibility vs. efficiency.

Practical impacts: FSW often wins for ROI.

Category | Vacuum Brazed Pros/Cons | Welded (FSW) Pros/Cons |

Pros | Clean joints, complex designs | Leak-free, cost-effective |

Cons | Expensive, slow | Limited complexity |

Advice: Consult experts for hybrid solutions.

(Word count: ~155)

Vacuum brazed and welded liquid cold plates each bring unique strengths to thermal management, from intricate designs to robust efficiency. With over 15 years as a one-stop heat solutions provider, KINGKA specializes in customized vacuum brazed and welded liquid cold plates, backed by advanced CNC machining and thermal simulations. Reach out at sales2@kingkatech.com for tailored advice that delivers reliability and performance.