Views: 4 Author: Site Editor Publish Time: 2025-12-15 Origin: Site

The real differences between liquid cold plates and heat sinks lie in their heat transfer mechanisms: heat sinks use passive convection to air, while liquid cold plates use active liquid circulation for superior, localized heat removal. This distinction dictates their suitability for different heat loads and environments.

In the world of thermal management, both liquid cold plates and heat sinks are crucial components designed to dissipate heat from electronic devices and other high-power systems. While their ultimate goal is the same—to keep components cool—their operational principles, capabilities, and ideal applications diverge significantly. Understanding these differences is key to selecting the optimal solution for any given thermal challenge.

The fundamental difference in heat transfer mechanism is that heat sinks primarily rely on passive convection and radiation to ambient air, whereas liquid cold plates actively transfer heat to a circulating liquid, which then carries the heat away to a remote heat exchanger.

This distinction is critical, as it defines their respective efficiencies and limitations in managing thermal loads. One is a passive air-based solution, the other an active liquid-based system.

Heat sinks transfer heat primarily through conduction from the heat source to their base, then through conduction to their fins, and finally by convection and radiation from the fin surfaces to the surrounding ambient air.

Examples: A CPU heat sink with a fan uses forced convection to move more air over the fins. A simple finned aluminum heat sink on a power transistor relies on natural convection.

Key Takeaway: Heat sinks are essentially extended surfaces designed to maximize contact with air, relying on air movement (natural or forced) to carry heat away.

Heat Sink Heat Transfer Steps:

Conduction: From heat source to heat sink base.

Conduction: Through heat sink body and fins.

Convection & Radiation: From fins to ambient air.

Liquid cold plates transfer heat by conducting it from the heat source to their base, then to an internal network of channels, where a circulating liquid absorbs the heat through forced convection and transports it out of the system.

Examples: A liquid cold plate cooling an IGBT module in an inverter. The heated liquid then flows to a radiator (heat exchanger) where it dissipates heat to the air or another medium.

Key Takeaway: Liquid cold plates use a highly efficient liquid medium to capture heat directly at the source and move it to a more convenient location for dissipation.

Liquid Cold Plate Heat Transfer Steps:

Conduction: From heat source to cold plate base.

Conduction: Through cold plate material to internal channels.

Forced Convection: Liquid absorbs heat and circulates away.

The key design and construction differences are that heat sinks are typically solid metallic structures with external fins, while liquid cold plates are sealed metallic structures containing internal channels for fluid flow, requiring robust sealing and connection points.

These structural differences directly reflect their distinct heat transfer mechanisms and influence their manufacturing processes and material choices.

Heat sinks are designed with a large surface area, typically achieved through fins (extruded, skived, bonded, or folded), to maximize contact with the cooling air. They are often made from aluminum or copper.

Examples: Extruded aluminum heat sinks for general electronics. Skived fin copper heat sinks for high-power CPUs. Bonded fin heat sinks for custom, high-performance applications.

Key Takeaway: The primary design goal of a heat sink is to present as much surface area as possible to the air for efficient convection.

Heat Sink Design Features:

Fins: Increase surface area for air contact.

Materials: High thermal conductivity metals (Al, Cu).

Solid Structure: No internal fluid passages.

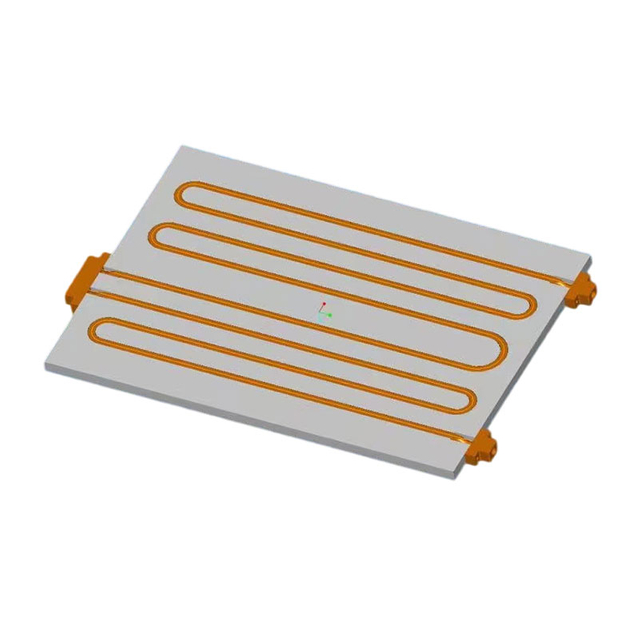

Liquid cold plates feature internal channels or passages through which a coolant flows, requiring a sealed construction to prevent leaks. They often incorporate advanced manufacturing techniques like FSW or vacuum brazing.

Examples: A deep-drilled copper cold plate for precise, high-density heat removal. An FSW (Friction Stir Welded) aluminum cold plate for lightweight EV battery cooling.

Key Takeaway: Cold plates are engineered for fluid containment and efficient internal heat transfer to the liquid, often involving complex internal geometries.

Liquid Cold Plate Design Features:

Internal Channels: For coolant flow.

Sealed Construction: Prevents leaks, requires robust joining.

Inlet/Outlet Ports: For fluid connection.

Liquid cold plates offer significantly higher heat dissipation capabilities and better temperature uniformity than heat sinks, especially for high heat flux applications, due to the superior thermal properties of liquids compared to air.

This performance gap widens considerably as heat loads increase, making cold plates the go-to solution for demanding thermal challenges.

Heat sinks are limited by the thermal conductivity and heat capacity of air, making them less effective for high heat flux densities or when precise temperature control is required, especially in confined spaces or high ambient temperatures.

Examples: A standard heat sink might struggle to cool a 500W power module in a compact enclosure. Its performance degrades significantly if the ambient air temperature rises.

Key Takeaway: Heat sinks are best for moderate heat loads where the ambient air is sufficiently cool and space allows for large fin structures.

Heat Sink Performance Limitations:

Air Properties: Limited by air's low thermal conductivity/capacity.

Ambient Temperature Dependence: Performance drops with higher ambient.

Space Constraints: Large fins needed for high performance.

Liquid cold plates offer superior performance advantages, including the ability to dissipate very high heat loads, achieve excellent temperature uniformity, and maintain stable temperatures independent of ambient air, by transferring heat to a remote cooling system.

Examples: A liquid cold plate can effectively cool a 1000W laser diode array in a compact space, maintaining its temperature within ±1°C. The heat can then be rejected by a chiller located far away.

Key Takeaway: Cold plates provide localized, high-density cooling with precise control, making them ideal for critical, high-power applications.

Liquid Cold Plate Performance Advantages:

High Heat Dissipation: Handles very high heat fluxes.

Temperature Uniformity: Achieves precise, even cooling.

Ambient Independence: Heat rejected remotely, less affected by local air.

Heat sinks are typically used in applications with moderate heat loads, where space is less critical, and air cooling is sufficient, such as consumer electronics or general industrial equipment. Liquid cold plates are reserved for high-power, high-density applications requiring precise thermal control, like EVs, data centers, and medical devices.

Their distinct performance envelopes dictate their most suitable applications across various industries.

Heat sinks are commonly used in desktop computers (CPUs, GPUs), LED lighting, power supplies, motor drivers, and other consumer or industrial electronics where heat loads are manageable by air convection.

Examples: The finned aluminum block on a voltage regulator. The large heat sink and fan assembly on a gaming PC's graphics card.

Key Takeaway: Heat sinks are ubiquitous in applications where cost-effectiveness and simplicity outweigh the need for extreme thermal performance.

Common Heat Sink Applications:

Consumer Electronics: PCs, TVs, audio equipment.

LED Lighting: Dissipating heat from high-power LEDs.

Power Electronics: Rectifiers, motor drives (moderate power).

Liquid cold plates are commonly used in electric vehicle battery packs, high-power industrial lasers, data center servers (direct-to-chip cooling), medical imaging equipment, and renewable energy inverters, where heat loads are intense and precise temperature control is vital.

Examples: Cooling the IGBT modules in an EV inverter. Maintaining the temperature of a supercomputer's processors.

Key Takeaway: Cold plates are essential for cutting-edge technologies that generate significant heat in compact spaces and demand stringent thermal stability.

Common Liquid Cold Plate Applications:

Electric Vehicles (EVs): Battery packs, power electronics.

Data Centers: Server CPUs/GPUs, high-performance computing.

Industrial Lasers: Cooling laser diodes and optics.

Heat sinks are generally more cost-effective and simpler to implement, as they are passive components. Liquid cold plates, however, involve higher initial costs and greater system complexity due to the need for a complete liquid cooling loop (pump, tubing, radiator, fluid).

This trade-off between cost/complexity and performance is a primary consideration in thermal solution selection.

The cost factors for heat sinks primarily include material costs (aluminum is cheaper than copper), manufacturing complexity (extrusion is cheaper than skiving or bonding), and the presence of a fan (adds cost and power consumption).

Examples: A simple extruded aluminum heat sink costs very little. A custom-machined copper heat sink with a high-performance fan can be significantly more expensive.

Key Takeaway: Heat sinks offer a wide range of cost points, generally correlating with their thermal performance and manufacturing method.

Heat Sink Cost Factors:

Material: Aluminum vs. Copper.

Manufacturing Process: Extrusion, stamping, skiving, bonding.

Fan/Blower: Adds cost and power.

Liquid cold plates involve higher cost and complexity due to the cold plate itself (precision manufacturing, sealing), the need for a complete liquid cooling system (pump, reservoir, tubing, radiator/chiller), and the associated maintenance and potential leak risks.

Examples: The cost of a custom FSW cold plate. The additional cost of a pump, fluid, and external heat exchanger. The need for leak detection and system maintenance.

Key Takeaway: While offering superior performance, liquid cold plates require a greater investment in components, system design, and ongoing maintenance.

Liquid Cold Plate Cost & Complexity Factors:

Cold Plate Manufacturing: Precision machining, sealing.

System Components: Pump, reservoir, tubing, radiator/chiller.

Installation & Maintenance: Leak prevention, fluid management.

Kingka, as a one-stop thermal solution provider, offers both high-quality customized liquid cold plates and various types of heat sinks, leveraging over 15 years of expertise in thermal management and precision manufacturing to meet diverse client needs.

Our comprehensive capabilities allow us to recommend and produce the most suitable thermal solution, whether it's a simple heat sink or a complex liquid cooling system.

Kingka offers a wide range of heat sink solutions, including extruded, skived fin, bonded fin, cold forged, and die-cast heat sinks, utilizing thermal analysis software to design optimal air-cooling solutions for natural or forced convection.

Examples: We provide custom extruded heat sinks for telecom equipment and high-performance skived fin heat sinks for industrial automation.

Key Takeaway: Kingka's diverse manufacturing processes ensure we can produce the right heat sink for any air-cooling requirement.

Kingka's Heat Sink Offerings:

Extruded Heat Sinks: Cost-effective, versatile.

Skived Fin Heat Sinks: High density, good performance.

Bonded Fin Heat Sinks: Custom designs, high aspect ratio.

Kingka provides advanced liquid cold plate solutions, including copper/stainless steel tube, FSW, deep drilled, vacuum brazed, and assembled cold plates, designed to transfer high heat loads to a liquid cooling system.

Examples: Our FSW liquid cold plates are ideal for EV battery cooling due to their lightweight and robust construction. Deep-drilled cold plates offer precise, high-performance cooling for semiconductor equipment.

Key Takeaway: Kingka's expertise in various liquid cold plate technologies allows us to tackle the most demanding thermal challenges.

Kingka's Liquid Cold Plate Offerings:

FSW Liquid Cold Plates: Lightweight, high performance.

Deep Drilled Cold Plates: Precision, high heat flux.

Vacuum Brazed Cold Plates: Complex geometries, robust.

While both liquid cold plates and heat sinks serve the fundamental purpose of dissipating heat, their operational principles, design, performance capabilities, and ideal applications are distinctly different. Heat sinks are passive, air-based solutions best suited for moderate heat loads and less critical temperature control. Liquid cold plates, conversely, are active, liquid-based systems offering superior heat dissipation, precise temperature uniformity, and independence from ambient air, making them indispensable for high-power, high-density, and mission-critical applications. Understanding these real differences is crucial for engineers and designers to make informed decisions, ensuring optimal thermal management for their specific needs. Kingka, with its extensive experience and diverse manufacturing capabilities, is uniquely positioned to provide both tailored heat sink and advanced liquid cold plate solutions, acting as a trusted one-stop thermal partner.