Views: 7 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

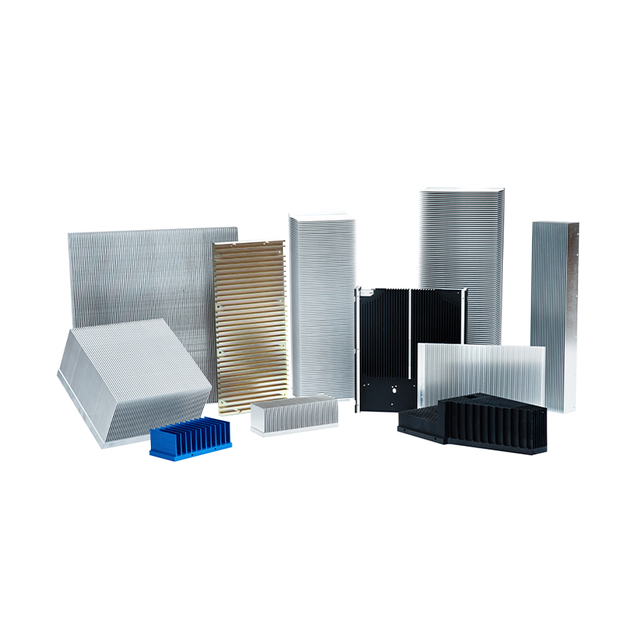

Choosing the right heat sink material is paramount for effective thermal management, directly impacting a device's performance, longevity, and cost. While aluminum and copper are the most common choices due to their excellent thermal conductivity and manufacturing versatility, advanced materials like graphite and mixed compositions offer specialized benefits for unique applications, ensuring optimal heat dissipation across diverse electronic systems.

Ever wondered what keeps your high-powered electronics from melting down? It's all thanks to clever thermal management, and at the heart of it lies the humble heat sink. But not all heat sinks are created equal, and the material they're made from is a game-changer. The right heat sink material can make the difference between a device that runs smoothly for years and one that constantly overheats. Let's dive deep into the world of heat sink materials, exploring the pros and cons of each, and helping you understand which one is the best fit for your specific cooling challenges.

The choice of heat sink material isn't just a minor detail; it's a fundamental decision that dictates the efficiency and effectiveness of any thermal management system.

The heat sink material is crucial because it directly determines the heat sink's ability to absorb and dissipate thermal energy, impacting device performance, reliability, and lifespan. Materials with high thermal conductivity, like copper and aluminum, are essential for efficiently transferring heat away from sensitive electronic components, preventing overheating and ensuring stable operation.

Think of a heat sink as a thermal bridge, moving heat from a hot component to the cooler surrounding environment. The material of this bridge is critical because it governs how quickly and efficiently this heat transfer can occur. If the material isn't up to the task, heat will build up, leading to a cascade of problems:

Reduced Performance: Overheated components often "throttle" or slow down to protect themselves, leading to a noticeable drop in performance. Your gaming PC might stutter, or an industrial controller might become sluggish.

Shorter Lifespan: Prolonged exposure to high temperatures accelerates material degradation in electronic components, significantly shortening their operational life. This means more frequent replacements and higher maintenance costs.

Reliability Issues: Intermittent failures, unexpected shutdowns, or even permanent damage can occur if heat isn't managed effectively. In critical applications like medical devices or automotive systems, this can have serious consequences.

Safety Concerns: In extreme cases, uncontrolled heat can lead to component failure, smoke, or even fire, posing significant safety risks.

The primary characteristic we look for in a heat sink material is high thermal conductivity. This property measures how well a material conducts heat. The higher the thermal conductivity, the faster heat can move through the material and away from the heat source. Beyond conductivity, other factors like density, cost, machinability, and corrosion resistance also play a significant role in determining the suitability of a heat sink material for a given application.

When you think of a heat sink, chances are you're picturing one made of aluminum. It's the undisputed champion for a reason.

Aluminum is the most widely used heat sink material due to its excellent balance of thermal conductivity (around 167 W/m-K for common alloys), low density, high strength, and exceptional malleability. These properties make it cost-effective to manufacture into complex fin geometries via extrusion, providing efficient and lightweight thermal solutions for a vast array of applications.

Aluminum's popularity isn't just about being abundant; it's about a perfect blend of properties that make it incredibly versatile and cost-effective. It's the go-to heat sink material for everything from consumer electronics to industrial equipment.

Let's break down why aluminum shines as a heat sink material:

Good Thermal Conductivity: While not as high as copper, aluminum alloys like 6061 and 6063 offer a respectable thermal conductivity of approximately 167 W/m-K. This is more than sufficient for most applications, efficiently transferring heat away from components.

Low Density and Lightweight: With a density of about 2,700 kg/m³, aluminum is significantly lighter than copper. This is a huge advantage in portable devices, aerospace, and automotive applications where weight reduction is critical.

High Strength-to-Weight Ratio: Aluminum offers good mechanical strength, allowing for robust heat sink designs that can withstand physical stress without adding excessive weight.

Excellent Malleability and Machinability: This is where aluminum truly excels. It's easy to extrude, allowing manufacturers to create complex fin designs with high surface area at a low cost. It's also readily machinable for custom, intricate shapes.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer when exposed to air, providing good corrosion resistance. This can be further enhanced through anodizing, which also improves emissivity.

Cost-Effectiveness: Aluminum is relatively inexpensive compared to other high-performance thermal materials, making it ideal for mass production.

Two specific aluminum alloys are most frequently used as heat sink material:

Aluminum 6061 (A6061): Known for its good mechanical properties and weldability. It's often chosen for machined heat sinks where strength and precise features are required. Its thermal conductivity is around 167 W/m-K.

Aluminum 6063 (A6063): Highly favored for extrusion due to its excellent malleability. This allows for the creation of intricate, continuous fin profiles, making it very cost-effective for high-volume production. It also has a thermal conductivity of approximately 167 W/m-K.

Aluminum is the preferred heat sink material in a vast array of products:

Consumer Electronics: Smartphones, laptops, gaming consoles, routers, and LED TVs.

LED Lighting: Essential for dissipating heat from LED chips to ensure long lifespan and consistent light output.

Automotive Electronics: ECUs, infotainment systems, and power electronics in electric vehicles.

Industrial Automation: PLCs, motor drives, and power supplies.

Telecommunications: Base stations and network equipment.

The versatility and balanced properties of aluminum make it the go-to heat sink material for most thermal management challenges.

When maximum heat transfer is the absolute priority, and cost or weight are secondary concerns, copper steps into the spotlight.

Copper is a premium heat sink material renowned for its superior thermal conductivity, typically ranging from 385-400 W/m-K, making it ideal for high-power applications with extreme heat loads. While heavier and more expensive than aluminum, its exceptional ability to rapidly transfer heat prevents hot spots and ensures optimal performance in compact, high-density electronic systems.

Copper is the undisputed king of thermal conductivity among common metals. If you're dealing with a component that generates a lot of heat in a small space, and you need to move that heat away as fast as possible, copper is often the heat sink material of choice.

Here's why copper is chosen as a high-performance heat sink material:

Exceptional Thermal Conductivity: This is copper's biggest advantage. With a thermal conductivity of 385-400 W/m-K, it can conduct heat more than twice as efficiently as aluminum. This makes it superb for quickly drawing heat away from a concentrated source.

High Heat Capacity: Copper can absorb a significant amount of heat before its own temperature rises substantially, providing a good thermal buffer.

High Strength and Ductility: Copper is a strong and ductile metal, allowing it to be formed into various shapes, though it's less amenable to extrusion than aluminum.

Good Corrosion Resistance (with caveats): While copper can tarnish (oxidize) over time, it generally resists corrosion well in many environments. However, it can react with certain chemicals or moisture, sometimes requiring surface treatments.

Despite its thermal prowess, copper has some drawbacks:

High Density and Weight: Copper is significantly denser and heavier than aluminum (around 8,960 kg/m³). This can be a major issue in weight-sensitive applications.

Higher Cost: Copper is a more expensive raw material than aluminum, which drives up the overall cost of the heat sink.

More Difficult to Machine and Extrude: While machinable, copper is harder on tooling than aluminum, increasing manufacturing costs. Its lower malleability makes complex extrusion profiles challenging, often requiring alternative manufacturing methods like skiving or bonding.

Less Corrosion Resistant than Anodized Aluminum: While good, its natural corrosion resistance isn't always as robust as anodized aluminum, especially in certain environments.

Copper is typically reserved for applications where its superior thermal conductivity is absolutely necessary:

High-Performance Computing (HPC): CPUs and GPUs in gaming PCs, workstations, and servers, especially when overclocked.

Power Electronics: High-power IGBTs, MOSFETs, and rectifiers in industrial drives, inverters, and power supplies where concentrated heat needs rapid dissipation.

Medical Imaging Equipment: Components in MRI machines or X-ray systems that generate significant heat.

Laser Diodes: High-power laser systems require precise temperature control, often achieved with copper heat sinks or cold plates.

For situations demanding the absolute best in heat transfer, copper remains the premier heat sink material, despite its higher cost and weight.

Beyond traditional metals, advanced materials like graphite are gaining traction, offering unique thermal properties.

Graphite, particularly pyrolytic graphite sheets (PGS), is an emerging heat sink material known for its exceptionally high in-plane thermal conductivity (up to 1700 W/m-K), making it ideal for ultra-thin, lightweight thermal spreading in compact electronics. While its through-plane conductivity is low, its anisotropic nature, combined with its low density and flexibility, offers unique advantages for space-constrained applications like smartphones and tablets.

When you think of graphite, you might picture pencil lead. But advanced forms of graphite, especially pyrolytic graphite sheets (PGS), are revolutionizing thermal management in specific niches. This heat sink material offers a fascinating blend of properties that traditional metals can't match.

Graphite's unique crystalline structure gives it distinct thermal advantages:

Extremely High In-Plane Thermal Conductivity: This is graphite's standout feature. Certain forms of graphite can have thermal conductivity values as high as 1500-1700 W/m-K along their plane. This is significantly higher than even copper, making it an incredible heat spreader.

Anisotropic Thermal Conductivity: This means its thermal conductivity is different in different directions. While excellent in-plane, its through-plane (perpendicular to the sheet) conductivity is very low (around 5-15 W/m-K). This can be an advantage for directing heat away from a component while insulating it from other layers.

Ultra-Lightweight: Graphite is extremely light, with a density much lower than aluminum or copper. This is crucial for portable and wearable electronics.

Thin and Flexible: Pyrolytic graphite sheets can be made incredibly thin (tens of microns) and are flexible, allowing them to conform to complex shapes and fit into tight spaces.

Electrically Conductive: Like metals, graphite is electrically conductive.

Despite its impressive thermal spreading capabilities, graphite has limitations:

Low Through-Plane Conductivity: While a benefit for some applications, the very low through-plane conductivity means it's not effective for transferring heat through a thick block. It's primarily a heat spreader.

Fragility: Thin graphite sheets can be brittle and require careful handling and integration.

Cost: Advanced graphite materials are generally more expensive than aluminum and often copper, limiting their use to premium or specialized applications.

Integration Challenges: Attaching graphite sheets to components and ensuring good thermal contact can be more complex than with solid metal heat sinks.

Graphite is becoming a preferred heat sink material in cutting-edge, compact devices:

Smartphones and Tablets: Used as thin heat spreaders to move heat away from powerful processors and display drivers to the device's casing, preventing hot spots and improving user comfort.

Wearable Devices: Smartwatches and other wearables benefit from graphite's lightweight and thin profile for thermal management.

Compact Electronics: Any device where space is extremely limited, and heat needs to be spread over a larger area quickly.

LED Backlighting: In some displays, graphite sheets help spread heat from LED arrays.

Graphite, as a heat sink material, represents a significant advancement for thermal management in the era of miniaturization and high-performance portable electronics.

Sometimes, the best solution isn't a single material, but a clever combination, creating hybrid heat sinks.

Mixed composition heat sinks leverage the complementary properties of different materials, such as a copper base for superior heat absorption and an aluminum fin structure for efficient heat dissipation and weight reduction. These hybrid designs, often created through bonding or brazing, optimize thermal performance for specific applications by combining the strengths of various heat sink materials while mitigating their individual drawbacks.

No single heat sink material is perfect for every scenario. That's why engineers often turn to mixed compositions, combining two or more materials to create a hybrid heat sink that offers the best of both worlds. This approach allows for highly optimized thermal solutions that can address complex cooling challenges.

This is the most common type of mixed composition heat sink.

Concept: The idea is to use copper where its high thermal conductivity is most critical – directly at the heat source – and aluminum for the rest of the heat sink where its lightweight and cost-effective properties are beneficial.

Design: Typically, a copper base plate is attached to the heat-generating component. This base plate quickly absorbs and spreads the heat. An aluminum fin structure is then bonded, brazed, or sometimes even integrated via friction stir welding (FSW) to the copper base. The aluminum fins then efficiently dissipate this heat to the ambient air.

Advantages:

Optimized Performance: Achieves high heat absorption from the source (copper) combined with efficient, lightweight, and cost-effective heat dissipation (aluminum fins).

Cost-Effective: Reduces the overall amount of expensive copper needed compared to an all-copper heat sink.

Weight Reduction: Significantly lighter than an all-copper solution.

Manufacturing: These hybrids are often created through:

Soldering/Brazing: Permanently joining the copper base to the aluminum fins.

Epoxy Bonding: Using thermally conductive epoxy to attach the components.

Friction Stir Welding (FSW): A solid-state joining process that creates a strong metallurgical bond without melting, often used for liquid cold plates but adaptable for heat sinks.

Examples: High-performance CPU coolers, power electronics modules, and some LED lighting applications where a balance of performance, weight, and cost is crucial.

While copper-aluminum is dominant, other combinations exist:

Heat Pipes with Aluminum/Copper Fins: Heat pipes, which use a phase-change fluid for extremely efficient heat transfer, are often integrated into an aluminum or copper fin structure. The heat pipe rapidly moves heat from the source to the fins, which then dissipate it. This is a very common hybrid approach.

Vapor Chambers with Aluminum/Copper Fins: Similar to heat pipes but designed for 2D heat spreading, vapor chambers can be used as a base, with aluminum or copper fins attached for dissipation.

Graphite-Metal Composites: Thin graphite sheets can be bonded to metal bases (aluminum or copper) to enhance heat spreading in specific areas, especially in compact devices.

Mixed composition heat sinks demonstrate that the optimal heat sink material solution often involves a thoughtful combination of materials, each playing to its strengths to achieve superior thermal performance.

While aluminum, copper, and graphite dominate, the world of thermal management also includes other specialized heat sink material options for niche applications.

Beyond the common choices, specialized heat sink materials like silicon carbide (SiC) and aluminum matrix composites (AMCs) offer unique advantages for extreme environments or specific performance needs. SiC provides excellent thermal conductivity and high strength at elevated temperatures, while AMCs combine lightweight properties with tailored thermal expansion, catering to demanding applications in aerospace, defense, and high-power electronics.

For certain demanding applications, the standard heat sink material options might not be enough. This is where advanced and specialized materials come into play, offering unique properties tailored to extreme conditions or very specific performance requirements.

Silicon carbide is a ceramic material known for its extreme properties.

Properties:

High Thermal Conductivity: Can have thermal conductivity ranging from 100-270 W/m-K, comparable to or even better than aluminum.

Extremely High Hardness and Strength: One of the hardest materials known, making it incredibly durable.

High Temperature Resistance: Can operate at much higher temperatures than metals without degradation.

Low Thermal Expansion: Excellent dimensional stability over temperature changes.

Lightweight: Relatively low density.

Disadvantages:

Brittleness: Like most ceramics, it's brittle and susceptible to fracture under impact.

High Cost: Very expensive to produce and machine.

Difficult to Machine: Requires specialized diamond tooling.

Applications: High-power density modules, aerospace components, and other applications where extreme temperatures, harsh environments, and high reliability are critical, and cost is less of a concern.

These are composite materials where ceramic particles (like silicon carbide or aluminum nitride) are embedded in an aluminum matrix.

Properties:

Tailored Thermal Expansion: A key advantage is the ability to match the Coefficient of Thermal Expansion (CTE) of other components (like silicon chips), reducing thermal stress and improving reliability.

Improved Thermal Conductivity: Can achieve thermal conductivity higher than pure aluminum, sometimes approaching copper.

Lightweight: Retains the lightweight advantage of aluminum.

High Stiffness and Strength: Enhanced mechanical properties compared to pure aluminum.

Disadvantages:

Higher Cost: More expensive than pure aluminum.

More Complex Manufacturing: Requires specialized processing techniques.

Applications: Aerospace and defense electronics, high-power modules, and microelectronics packaging where CTE matching is crucial to prevent fatigue failures.

While not a structural heat sink material in the traditional sense, PCMs are often integrated into heat sink designs.

Concept: PCMs absorb large amounts of latent heat during a phase change (e.g., melting from solid to liquid) at a specific temperature. This provides a temporary thermal buffer.

Properties: High latent heat of fusion, specific melting point.

Applications: Used in conjunction with conventional heat sinks to manage transient heat spikes, providing a "thermal battery" effect in devices like laptops or medical equipment that experience intermittent high power loads.

These specialized heat sink material options highlight the continuous innovation in thermal management, addressing the ever-growing demands of advanced electronics.

Choosing the optimal heat sink material is a multi-faceted decision, balancing performance, cost, and practical considerations.

Selecting the ideal heat sink material involves a careful evaluation of thermal conductivity, density, cost, and manufacturability, alongside specific application requirements like operating temperature, environmental conditions, and mechanical constraints. The goal is to achieve efficient heat dissipation within budget and design limitations, ensuring long-term device reliability and performance.

It's rarely a simple choice. Engineers must weigh several critical factors to determine the best heat sink material for a given project.

Heat Load (Watts): How much heat does the component generate? High heat loads often push towards materials with higher thermal conductivity like copper or advanced composites.

Temperature Rise (ΔT): What is the maximum allowable temperature rise for the component? This dictates how efficiently the heat sink must perform.

Airflow (Natural vs. Forced Convection):

Natural Convection: Relies on ambient air movement. Requires larger surface areas and often materials with good emissivity (like anodized aluminum).

Forced Convection: Uses fans to move air. Allows for smaller heat sinks and can utilize materials with slightly lower conductivity if airflow is strong.

Thermal Spreading: How quickly does heat need to spread from a small hot spot to a larger area? Materials like graphite or copper excel here.

Weight Restrictions: For portable devices, aerospace, or automotive applications, low density materials like aluminum or graphite are crucial.

Space Limitations: Compact designs might necessitate thin, flexible materials (graphite) or highly optimized fin structures (extruded aluminum, skived copper).

Mechanical Strength: Does the heat sink need to support other components or withstand vibrations/shocks? Materials like aluminum and copper offer good structural integrity.

Thermal Expansion (CTE Matching): In some cases, matching the CTE of the heat sink material to the component it's cooling is vital to prevent stress and fatigue failures, especially with large chips or extreme temperature cycles. AMCs are often chosen for this.

Operating Temperature Range: Some materials perform better or worse at extreme temperatures. SiC, for example, excels at very high temperatures.

Corrosion Resistance: For humid or chemically aggressive environments, materials with inherent corrosion resistance (like aluminum with anodizing) are preferred.

Electrical Conductivity: Is electrical isolation required, or is electrical contact acceptable? Most metals are conductive, while some ceramics are insulators.

EMI Shielding: Some heat sink materials can also contribute to EMI shielding.

Material Cost: The raw material cost of copper is higher than aluminum, and specialized materials are even more expensive.

Manufacturing Cost: The ease of shaping and processing the heat sink material significantly impacts the final cost. Aluminum's excellent extrudability makes it very cost-effective for complex fin designs. Copper is harder to extrude, leading to more expensive manufacturing methods for high fin densities.

Volume: For high-volume production, cost-effective manufacturing processes like aluminum extrusion are highly desirable. For low-volume or prototypes, CNC machining of aluminum or copper is more common.

By carefully considering all these factors, engineers can make an informed decision about the optimal heat sink material that balances performance, reliability, and cost for their specific application.

The choice of heat sink material often dictates the manufacturing process, which in turn affects design possibilities and cost.

The manufacturing process for a heat sink material is intrinsically linked to its properties, with aluminum commonly extruded for cost-effective, high-volume production of complex fin geometries. Copper often requires skiving or bonding for high fin density due to its lower malleability, while specialized materials like graphite involve unique fabrication methods, each process optimized to leverage the material's strengths for efficient heat dissipation.

The journey from raw material to a finished heat sink involves various manufacturing techniques, each optimized for the specific properties of the chosen heat sink material.

Aluminum's malleability makes it incredibly versatile for manufacturing.

Extrusion: This is the most common method for aluminum. Molten aluminum (typically A6063) is pushed through a die to create long, continuous profiles with intricate fin designs. It's highly cost-effective for high-volume production.

Examples: Standard plate fin, round pin, and elliptical fin heat sinks.

CNC Machining: For custom, complex, or low-volume designs, solid blocks of aluminum (often A6061) are precisely milled. This offers high design flexibility.

Examples: Custom enclosures with integrated fins, specialized heatsinks for unique component layouts.

Stamping/Forming: Aluminum sheets are cut and bent into simpler heat sink shapes, ideal for very high-volume, low-cost applications.

Examples: Small, low-profile heat sinks for individual components on a PCB.

Die Casting: Molten aluminum is injected into a mold. Good for complex 3D shapes and high volumes, though thermal performance might be slightly lower than extruded due to porosity.

Examples: Heat sinks with integrated mounting features or complex base geometries.

Copper's properties require different approaches for high fin density.

CNC Machining: Similar to aluminum, copper blocks can be machined for custom designs, though it's harder on tooling.

Skiving: A specialized process where a sharp blade shaves off thin fins from a solid copper block. This creates very high fin densities and aspect ratios.

Examples: High-performance CPU coolers, power electronics modules.

Bonded Fins: Individual copper fins are soldered or epoxied to a copper base. This allows for very tall and thin fins that wouldn't be possible with extrusion.

Examples: Large heat sinks for industrial power supplies.

Forging: Compressing copper into a die to create dense, strong heat sinks, often used for pin fin designs.

Graphite's unique form factor requires specialized handling.

Sheet Fabrication: Pyrolytic graphite is typically manufactured as thin sheets through a high-temperature process.

Cutting and Lamination: These sheets are then precisely cut to shape and often laminated with protective layers or adhesives for integration into devices.

Integration: Graphite sheets are usually bonded to heat sources and spread heat to a larger surface, often the device casing or an underlying metal heat sink.

These combine processes for different materials.

Brazing/Soldering: Commonly used to join copper bases to aluminum fins, creating a strong metallurgical bond.

Friction Stir Welding (FSW): A solid-state joining process that creates high-strength bonds between dissimilar metals, often used for liquid cold plates but applicable to heat sinks.

Epoxy Bonding: Thermally conductive epoxies can be used to join different materials, offering flexibility in design.

Understanding these manufacturing processes is key to realizing the full potential of each heat sink material and achieving optimal thermal performance within design and budget constraints.

The journey through the world of heat sink material reveals a complex interplay of thermal science, material properties, and manufacturing ingenuity.

In conclusion, selecting the optimal heat sink material is a critical engineering decision that balances thermal performance, cost, weight, and manufacturability. While aluminum remains the versatile, cost-effective workhorse for most applications, copper excels in high-heat density scenarios, and advanced materials like graphite offer unique solutions for ultra-thin, lightweight designs. Understanding these material characteristics and their corresponding manufacturing processes is essential for developing efficient and reliable thermal management systems that ensure the longevity and performance of modern electronics.

There's no single "best" heat sink material; rather, there's an optimal choice for every specific application. Aluminum offers an unbeatable balance of performance, cost, and versatility, making it the go-to for the vast majority of electronic cooling needs. Copper steps in when extreme thermal conductivity is paramount, handling the most demanding heat loads. And emerging materials like graphite push the boundaries of thermal spreading in miniaturized, high-performance devices.

Ultimately, effective thermal management hinges on a deep understanding of the heat source, the environment, and the capabilities of various heat sink material options. By carefully considering all these factors, engineers can design robust and efficient cooling solutions that keep our electronic world running smoothly.

Are you grappling with complex thermal challenges? Don't let overheating compromise your product's performance or lifespan. KingKa Tech is your trusted one-stop thermal solution provider, specializing in high-quality customized liquid cold plates, heat sinks, and precision CNC machining services. With over 15 years of experience and a dedicated R&D team, we offer free technical design support, thermal analysis, and airflow simulations to help you select and implement the perfect heat sink material and design for your unique needs. Contact us today to optimize your thermal management and ensure your innovations stay cool under pressure!