Views: 33 Author: Site Editor Publish Time: 2021-02-21 Origin: Site

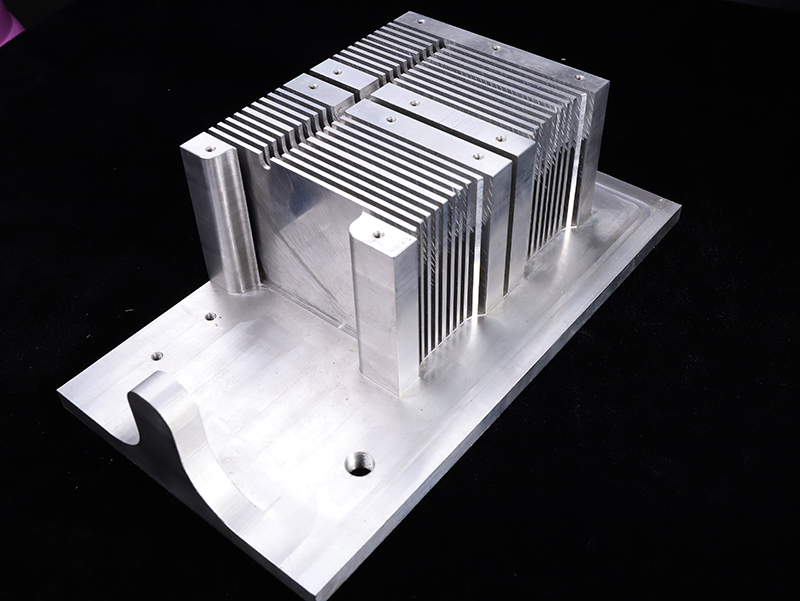

Kingka is a professional custom heat sink manufacturer. Aluminum profile heat sinks are processed from aluminum profiles and are made into heat sinks. In the production process of aluminum heat sink, cutting the aluminum profile into semi-finished products and then performing CNC processing is a kind of delicate operation. There are many problems in the operation process that need to be paid attention to. If the processing is improper, the quality of the aluminum heat sink will be unqualified.

For example, when processing aluminum heat sinks on a horizontal machining center, multi-station processing is generally required, so the best position of the parts (including fixtures) on the machine table must be considered. In the process preparation process, it is necessary to consider the stroke of the machine tool and optimize the tool length of each part. If it is not considered carefully, it will directly cause the machine tool to overtravel, change the tool, thereby affecting the machining accuracy or re-entering the trial cutting stage, etc. It is a waste of time. It also increases the possibility of waste, so this issue should be considered before processing aluminum heat sinks.

If the CNC machine tool has the function of automatic tool change, its biggest disadvantage is the tool cantilever machining, and the boring die, spindle, etc. cannot be used during the machining process. When machining multi-station parts, it is necessary to calculate the distance from each station to the end of the machine tool spindle very accurately, and select the best tool length. After setting, perform necessary inspections during the first aluminum heat sink forming.

In addition, the following issues should be paid attention to in the CNC machining of aluminum heat sinks:

(1) If the height of the custom aluminum heat sink is too high, especially when processing some high-power heat sinks, blades of different lengths should be used to separate the holes. After opening the holes, use a large blade and then use the blade to remove the remaining material.

(2) Use flat-bottomed knives to machine planes, and use replacement spherical tools to reduce machining time; if there is an inclination and the inclination is integral, use an inclination tool.

(3) Reasonably set the tolerance to balance the machining accuracy and the computer calculation time, and do more procedures to reduce the cutting time.

(4) If the material hardness of the aluminum profile heat sink is high, down milling can be used; if the aluminum profile heat sink is low, down milling can be selected. In addition, thickening, up-cut milling, finishing milling.

(5) The tool material itself is good, low hardness, suitable for rough machining; the tool material itself is poor, suitable for fine machining;

(6) Be careful not to touch the gears of the aluminum heat sink during the processing, so as not to damage the gears, especially for individual heat sinks with anodes.

The above-mentioned problems are all problems that should be paid attention to in the processing of aluminum heat sinks. Skilled technicians will generally notice these problems. If it is a beginner or an employee who is new to heat sink processing, more guidance is needed.