Views: 26 Author: Site Editor Publish Time: 2024-07-30 Origin: Site

In the rapidly evolving field of electronics cooling, heat dissipation efficiency is crucial for device performance and longevity. With advancing technology, the demand for effective cooling solutions like heat exchangers and radiators has never been higher. However, radiator design often suffers from common yet overlooked mistakes that can compromise cooling efficiency.

This article delves into the "8 Common Radiator Design Mistakes in Electronics Cooling and How to Avoid Them." This comprehensive guide aims to identify these pitfalls and provide practical solutions, enabling designers and engineers to optimize their radiator designs for maximum efficiency and reliability.

A critical oversight in radiator design is failing to assess the heat load accurately. With a proper understanding of the thermal demands, radiators may become efficient, overworked, or underutilized.

Detailed thermal analysis and simulation tests are the key to avoiding this mistake. By thoroughly evaluating the heat load requirements before the design phase, engineers can ensure the radiator is adequately sized and capable of handling the anticipated thermal stress.

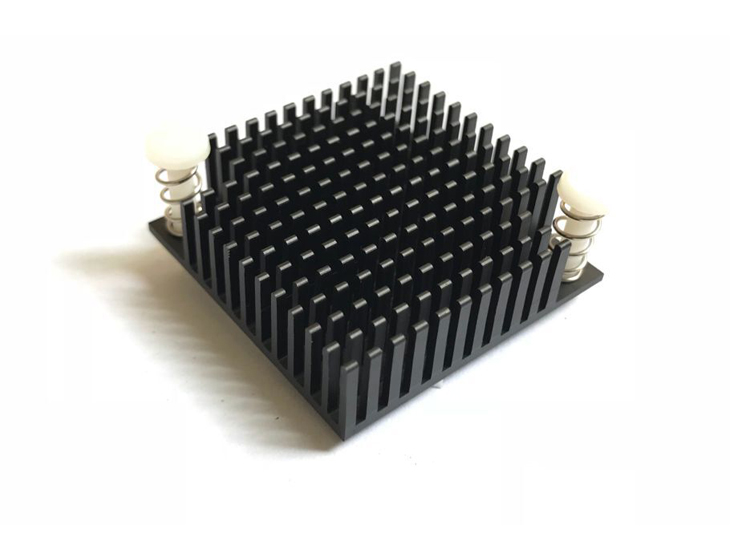

Using materials with inadequate thermal conductivity is a common misstep. Materials that cannot efficiently transfer heat will compromise the radiator's effectiveness.

The solution is straightforward: choose materials with high thermal conductivity. Metals like aluminum or copper are often preferred in radiator designs due to their excellent heat transfer properties.

Selecting a radiator that is too large or too small for the intended application can lead to inefficiencies. An oversized radiator may result in unnecessary bulk and cost, whereas an undersized one can fail to meet the cooling requirements.

The ideal approach is to choose a radiator size that aligns with the device's heat output. This involves calculating the required thermal dissipation capacity and selecting a radiator that matches these needs, considering the available space and configuration.

Neglecting the design aspects that facilitate proper airflow can lead to heat accumulation and reduced cooling efficiency. A radiator needs a well-thought-out design that supports adequate air circulation.

To mitigate this, ensure the radiator design promotes efficient airflow. This can be achieved through strategic placement, orientation, and, if necessary, the incorporation of fans to enhance air movement and heat exchange.

A common oversight in radiator design is poor management of the thermal interface between the radiator and the heat source. Inadequate thermal interface materials or improper application can lead to high thermal resistance, hindering efficient heat transfer.

Utilizing high-quality thermal interface materials is crucial. These materials should be applied correctly to ensure minimal thermal resistance and optimal contact between the heat source and the radiator. This step is critical for maximizing heat transfer efficiency.

Overdesigning a radiator can lead to increased costs and maintenance difficulties. Complexity in design only sometimes translates to better performance and can often be counterproductive.

The key is to adopt a design that is simple yet effective. Avoid unnecessary complexities that do not contribute to improved performance or efficiency. A streamlined design often provides better results and is generally easier to manufacture and maintain.

Failing to consider the environmental conditions in which the radiator will operate is a significant oversight. Ambient temperature, humidity, and airflow can significantly influence the radiator's performance.

To address this, the design should account for the environmental conditions. This includes considering ambient temperature and humidity variations and ensuring the radiator can function efficiently under these varying conditions.

Designing a radiator that is hard to maintain and clean can lead to reduced efficiency over time. Accumulation of dust and debris can obstruct airflow and impede heat transfer.

The solution is to design a radiator that is easy to maintain and clean. This can involve features like removable parts for easy access or designs that naturally minimize dust accumulation. Regular maintenance should be straightforward to ensure long-term efficiency.

Through this exploration of the "8 Common Radiator Design Mistakes and How to Avoid Them," we have highlighted how each aspect of radiator design is crucial for achieving optimal performance and reliability. Avoiding these common pitfalls is not just about enhancing efficiency; it's about ensuring the longevity and effectiveness of the cooling system.

For those seeking state-of-the-art cooling solutions, it's imperative to partner with a manufacturer that understands these nuances. We recommend KingKa, a leading manufacturer of liquid cold plates and radiators. KingKa is dedicated to delivering innovative cooling solutions tailored to the growing thermal management demands. Whether standard products or custom services, KingKa's expertise and experience guarantee that your cooling needs are satisfied with the highest efficiency and quality standards.