Views: 3 Author: Site Editor Publish Time: 2025-10-20 Origin: Site

Choosing the best heatsink material is crucial for effective thermal management, directly impacting device performance and longevity. While copper offers superior thermal conductivity for high-performance, high-heat applications, aluminum provides a cost-effective, lightweight solution for general use. Other materials like heat pipes, graphite, and ceramics offer specialized benefits depending on specific application requirements.

Ever wonder what keeps your gadgets from melting down when they're working hard? It's often a trusty heatsink, quietly whisking away heat to keep everything running smoothly. But not all heatsinks are created equal, and the material they're made from plays a huge role in how well they do their job. Picking the right material isn't just about what looks good; it's about ensuring your electronics stay cool, perform optimally, and last longer. Let's dive into the fascinating world of heatsink materials and figure out which one is the champion for your specific cooling needs!

Before we pit materials against each other, let's quickly understand why this choice is so critical for your electronics.

Heatsink material is paramount because it directly dictates the component's ability to conduct and dissipate heat efficiently, which is essential for preventing overheating, performance degradation, and permanent damage to electronic devices. Materials with high thermal conductivity ensure heat is rapidly moved away from sensitive components, maintaining them within their safe operating temperatures.

Electronic components, from the tiny chips in your smartphone to the powerful processors in a server, generate heat when electrical current flows through them. This heat, if not managed, can lead to a host of problems: slower performance, unexpected shutdowns, and even irreversible damage. A heatsink's job is to absorb this heat and transfer it to the surrounding air. The material's thermal conductivity—how well it transfers heat—is a key factor in this process. A material that conducts heat poorly will essentially trap heat, making the heatsink ineffective, while a highly conductive material will efficiently move heat away, ensuring the device stays cool and reliable.

Heatsinks work on the basic principle that heat naturally moves from a hotter area to a cooler one. They achieve this through two main processes: conduction and convection. First, heat is conducted from the hot electronic component into the heatsink's base. Then, it spreads through the heatsink's body and fins. Finally, the heat is transferred from the heatsink's surface to the surrounding air, primarily through convection. The material's ability to conduct heat internally and its surface properties for convection are what make it suitable for a heatsink. Without efficient heat transfer, your devices would quickly reach critical temperatures, leading to failure.

Choosing the wrong heatsink material can have serious repercussions for your electronic devices. If the material can't effectively pull heat away, the component will overheat, leading to performance issues like "thermal throttling" where the device intentionally slows down to prevent damage. In severe cases, prolonged overheating can cause permanent damage to internal components, shortening the device's lifespan or leading to complete failure. Imagine a high-performance gaming PC constantly slowing down or crashing because its CPU heatsink isn't up to the task—that's the real-world impact of a suboptimal material choice.

When maximum heat transfer is the goal, one material consistently stands out.

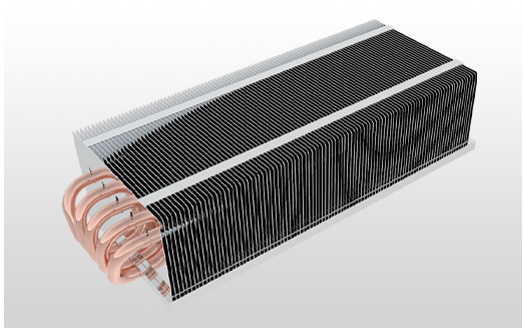

Copper is widely considered the best heatsink material for high-performance applications due to its exceptionally high thermal conductivity, allowing it to rapidly absorb and dissipate heat from intensely hot electronic components. While heavier and more expensive than aluminum, copper's superior heat transfer capabilities make it ideal for compact, high-power devices like gaming CPUs and GPUs where efficient cooling is critical.

Copper's reputation as a thermal powerhouse is well-earned. It boasts one of the highest thermal conductivities among commonly used metals, meaning it can move heat away from a source incredibly fast. This makes it perfect for situations where a component generates a lot of heat in a small area, like a powerful processor. The quicker heat can be drawn away, the cooler the component stays, and the better it performs.

You'll typically find copper heatsinks in applications where performance is paramount and heat loads are significant.

High-End Gaming PCs: CPUs and GPUs in gaming rigs generate immense heat, and copper heatsinks (often combined with heat pipes) are crucial for keeping them cool enough to prevent throttling and maintain high frame rates.

Workstations and Servers: Professional workstations and data center servers house powerful processors that run continuously under heavy loads. Copper heatsinks are essential here for reliable, sustained performance.

Power Electronics: In power supplies and other high-current applications, components can get extremely hot. Copper's excellent conductivity ensures this heat is managed effectively, maintaining reliability.

While copper is a fantastic heat conductor, it does come with a few trade-offs. It's heavier than aluminum, which can be a concern in portable devices, and it's generally more expensive. Also, copper can oxidize or "rust" over time, so it often requires a protective coating. Despite these minor drawbacks, for pure thermal performance, copper remains the top choice.

While copper takes the crown for raw thermal power, aluminum offers a compelling balance of performance and practicality.

Aluminum is a highly popular heatsink material due to its excellent balance of good thermal conductivity, lightweight properties, and cost-effectiveness, making it suitable for a vast range of electronic devices. It's easier to manufacture into complex shapes than copper and resists corrosion well, making it a versatile and economical choice for most general cooling applications.

Aluminum might not conduct heat quite as well as copper, but it's still very good at it. What makes aluminum truly shine is its combination of other desirable properties. It's significantly lighter than copper, which is a huge advantage for portable electronics or applications where overall weight is a concern. Plus, it's much more affordable, making it the go-to material for mass-produced consumer electronics. Aluminum also has good natural corrosion resistance, which can be further enhanced through anodization.

You'll find aluminum heatsinks almost everywhere, from everyday gadgets to industrial equipment.

Consumer Electronics: From the chips in your TV to the power regulators in your home router, aluminum heatsinks are widely used due to their cost-effectiveness and sufficient cooling performance for moderate heat loads.

LED Lighting: Many LED light fixtures use aluminum heatsinks to dissipate the heat generated by the LEDs, ensuring their longevity and consistent light output.

Standard Computer Components: For mid-range CPUs and GPUs, or other components that don't reach extreme temperatures, aluminum heatsinks provide adequate cooling without the premium cost or weight of copper.

Automotive Electronics: In cars, where weight is a factor and components need reliable cooling, aluminum heatsinks are frequently employed.

Aluminum's ease of manufacturing is another big plus. It can be easily extruded into various fin designs, stamped, or forged, allowing for cost-effective production of complex shapes that maximize surface area for heat dissipation. This versatility makes aluminum the undisputed workhorse of the heatsink world.

While copper and aluminum dominate the heatsink market, other materials offer unique advantages for specific, often high-tech, applications.

Beyond traditional metals, specialized heatsink materials like heat pipes, graphite, ceramics, and even diamond offer enhanced or unique thermal management properties for niche applications. Heat pipes provide exceptional thermal conductivity by leveraging phase change, while graphite and diamond offer ultra-lightweight or extremely high conductivity for compact or extreme-performance scenarios. Ceramics are chosen for their electrical insulation properties alongside heat dissipation.

Heat pipes aren't a solid material in the traditional sense, but rather a highly efficient heat transfer device often made with copper or aluminum. They work by using a sealed vacuum tube containing a working fluid (like water) that evaporates at the hot end, carrying heat as vapor, and then condenses at the cooler end, releasing the heat. This continuous evaporation-condensation cycle allows heat pipes to transfer heat hundreds of times more effectively than solid copper.

Applications: Laptops, high-performance CPU coolers, and compact electronics where heat needs to be moved efficiently over a distance.

Example: A laptop's CPU often has a heat pipe connected to a small fin stack, which is then cooled by a fan, allowing a powerful processor to fit into a thin chassis.

Graphite and its even more advanced form, graphene, are special types of carbon known for their excellent thermal conductivity and incredibly light weight. While not as efficient as copper in all directions, they can move heat very quickly along their planes.

Applications: Smartphones, tablets, and other ultra-compact devices where every gram and millimeter counts.

Example: High-end smartphones often use thin graphite sheets to spread heat away from the processor, preventing hot spots without adding significant bulk.

Ceramic heatsinks, often made from materials like aluminum nitride, are unique because they can conduct heat well while also being electrical insulators. This is a critical property in applications where you need to dissipate heat from an electronic component but also need to electrically isolate it from other parts of the system.

Applications: High-powered LEDs, power modules, and certain medical devices where electrical isolation is paramount.

Example: In some LED arrays, ceramic heatsinks are used to cool individual LEDs while preventing electrical interference between them.

Diamond, particularly synthetic diamond, boasts the highest known thermal conductivity of any material. It can dissipate heat incredibly quickly and efficiently.

Applications: Currently in early stages of development and niche high-performance applications, such as specialized military electronics or cutting-edge research equipment, where cost is no object and extreme thermal performance is required.

Example: Experimental high-frequency communication devices or ultra-compact, high-power lasers might benefit from diamond heatsinks to manage intense localized heat.

Composite materials combine two or more different substances to create a new material with tailored properties. For heatsinks, this often means combining materials like graphite and copper to get the best of both worlds—good heat dissipation with reduced weight or cost.

Applications: Advanced machines, aerospace, and high-tech electronics where a specific balance of thermal, mechanical, and weight properties is needed.

Example: A graphite/copper composite might be used in an aerospace application to achieve high thermal conductivity while keeping the component's weight to a minimum.

These specialized materials demonstrate that the "best" heatsink material isn't a one-size-fits-all answer; it's about finding the perfect match for the unique demands of each application.

With so many options, how do you pick the right heatsink material for your project? It boils down to a few critical factors.

Selecting the optimal heatsink material requires a careful evaluation of the component's heat generation, available space, weight constraints, and budget. Copper is ideal for high-heat, performance-critical applications, while aluminum offers a cost-effective, lightweight solution for most general uses. Specialized materials address unique needs like electrical isolation or extreme thermal conductivity in niche scenarios.

Here’s a practical guide to help you make an informed decision:

Heat Load (Power Dissipation): This is the absolute first thing to consider.

High Heat (e.g., >50W): If your component generates a lot of heat, like a high-end CPU or GPU, copper is often the best choice due to its superior thermal conductivity. You might also consider heat pipes for efficient heat transfer over distance.

Moderate Heat (e.g., 10-50W): For components with moderate heat output, aluminum usually offers a great balance of performance and cost.

Low Heat (e.g., <10W): For very low heat loads, even a small aluminum heatsink might be overkill, and sometimes no heatsink is needed, or a simple stamped aluminum solution suffices.

Space and Form Factor:

Compact, High Heat: Copper or heat pipes can achieve high cooling performance in a smaller volume.

Larger Space, Moderate Heat: Aluminum allows for larger, more intricate fin designs to maximize surface area for natural convection, often at a lower cost.

Ultra-Thin/Flexible: Graphite sheets might be considered for extremely thin devices like smartphones.

Weight Restrictions:

Weight-Sensitive (e.g., drones, portable devices): Aluminum is significantly lighter than copper. Graphite and graphene are even lighter and excellent for weight-critical applications.

Weight Not a Major Concern: Copper can be used without hesitation.

Cost and Budget:

Budget-Friendly: Aluminum is the most cost-effective option for most applications. Stamped aluminum heatsinks are particularly cheap for low-power uses.

Mid-Range Budget: Extruded aluminum or some bonded fin designs offer good performance for the price.

High Budget: Copper, heat pipes, ceramics, and advanced composites will be more expensive but offer superior or specialized performance. Diamond is currently the most expensive.

Electrical Isolation:

Requires Electrical Isolation: Ceramic heatsinks are ideal as they are electrically non-conductive while still dissipating heat.

Manufacturing Process: The chosen material often dictates the manufacturing process, which in turn affects cost and design complexity.

Extrusion: Best for aluminum, offering cost-effective, simple fin designs.

Skiving: Often used for copper, allowing for high fin density from a solid block.

CNC Machining: Offers the most design flexibility for complex geometries but is high cost and slow for high volumes, suitable for both aluminum and copper.

By systematically evaluating these factors, you can narrow down your choices and select the heatsink material that best meets your project's unique requirements, ensuring optimal thermal performance and device longevity.

In the intricate dance of electronics, heat management is a silent but crucial partner. The choice of heatsink material isn't just a technical detail; it's a strategic decision that directly impacts the performance, reliability, and lifespan of your devices.

Ultimately, there isn't a single "best" heatsink material; the optimal choice is highly dependent on the specific application's thermal load, space constraints, weight requirements, and budget. Copper reigns supreme for high-performance, high-heat applications due to its exceptional thermal conductivity, while aluminum offers a versatile, cost-effective, and lightweight solution for most general electronics. Specialized materials like heat pipes, graphite, and ceramics provide targeted benefits for unique challenges, ensuring that every electronic device can find its perfect cooling match.

Whether you're building a cutting-edge gaming rig that demands every ounce of cooling power, designing a sleek, silent consumer gadget, or engineering robust industrial equipment, understanding the strengths and weaknesses of each heatsink material is key. By carefully considering your specific needs, you can select the champion material that will keep your electronics running cool, stable, and performing at their best for years to come.

Ready to optimize your thermal management strategy? Don't leave your electronics' longevity to chance. KingKa Tech is your trusted one-stop provider for customized thermal solutions, including high-quality liquid cold plates, heat sinks, and precision CNC machining services. With over 15 years of expertise in thermal management and precision manufacturing, our R&D team is equipped to provide free technical design support, thermal analysis, and airflow simulations. Contact us today to discuss your project and discover how our tailored solutions can keep your innovations cool and reliable!