Views: 37 Author: Site Editor Publish Time: 2025-11-03 Origin: Site

Choosing the optimal heat sink material is critical for effective thermal management, with aluminum, copper, and graphite each offering distinct advantages and disadvantages. Aluminum provides a cost-effective, lightweight solution for moderate heat loads, while copper excels in thermal conductivity for high-power density applications. Graphite offers unique anisotropic properties for specialized needs, and mixed compositions leverage the strengths of multiple materials. A comprehensive analysis of thermal conductivity, density, cost, and manufacturing considerations is essential to select the best material for specific application requirements.

As electronics become more powerful and compact, managing heat is paramount for device reliability and lifespan. The right heat sink material is crucial. This article compares aluminum, copper, graphite, and mixed compositions, detailing their properties to help you choose the best solution for your thermal management needs.

To effectively dissipate heat, a heat sink material needs specific characteristics.

An effective heat sink material must possess high thermal conductivity to efficiently transfer heat away from the source, low density for minimal weight, and good manufacturability for cost-effective production of complex geometries. Additionally, its coefficient of thermal expansion should ideally match the component it cools to prevent stress, and it must offer a favorable cost-to-performance ratio, balancing thermal efficiency with budget constraints for optimal thermal management.

Key properties for heat sink materials include:

Thermal Conductivity (k): Measures heat transfer efficiency (W/(m·K)). Higher is better for rapid heat spreading.

Density (ρ): Mass per unit volume (g/cm³). Lower density is preferred for lightweight applications.

Coefficient of Thermal Expansion (CTE): How much a material expands with temperature (ppm/°C). Matching the component's CTE minimizes stress.

Manufacturability: Ease of shaping and processing into complex designs, impacting cost.

Cost: Raw material and processing expenses.

These properties form the basis for evaluating and selecting the right heat sink material.

Aluminum is a popular choice among heat sink materials due to its balanced properties.

Aluminum heat sinks are the industry's lightweight workhorse, widely favored for their excellent balance of thermal conductivity, low density, and cost-effectiveness. Typically manufactured through extrusion, casting, or machining, aluminum offers good heat dissipation for moderate power applications, making it a versatile and economical choice where weight and budget are key considerations, despite having lower thermal conductivity than copper.

Aluminum's widespread use comes from its combination of:

Thermal Conductivity: 180-220 W/(m·K) (e.g., 6061, 6063). Good, but not top-tier.

Density: Low, around 2.7 g/cm³, making it lightweight.

Cost: Relatively inexpensive for both raw material and processing.

Manufacturability: Highly versatile (extrusion, casting, machining, skived, bonded fins). Extrusion is very cost-effective for high volumes.

Corrosion Resistance: Good natural resistance, enhanced by anodizing.

CTE: Around 23 ppm/°C, suitable for many semiconductor packages.

Consumer electronics (laptops, LEDs)

Automotive electronics (ECUs)

Industrial controls, telecommunications

Advantage | Disadvantage |

Lightweight | Lower thermal conductivity than copper |

Cost-effective | Less effective for extremely high heat fluxes |

Excellent manufacturability |

Aluminum is ideal where a balance of performance, weight, and cost is crucial.

For maximum thermal conductivity among heat sink materials, copper is the top choice.

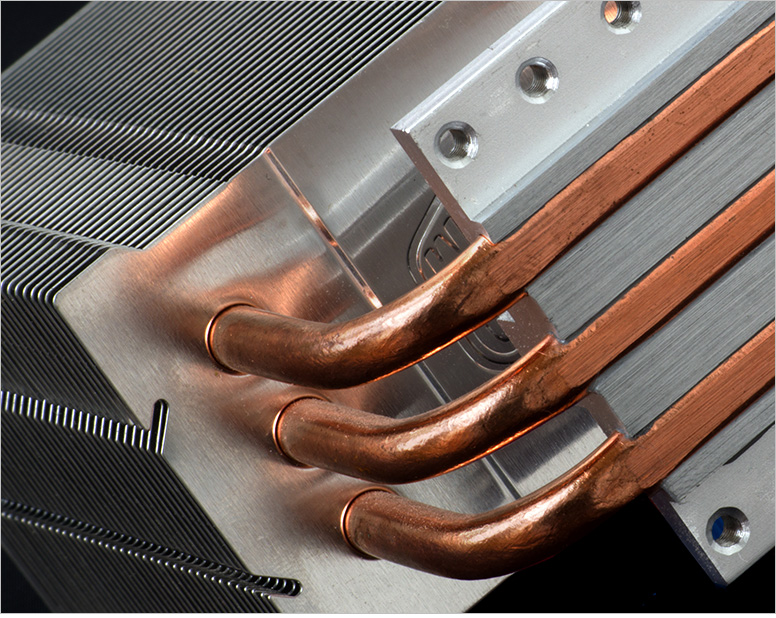

Copper heat sinks are renowned for their superior thermal conductivity, making them the preferred choice for high-power density applications where efficient heat transfer from concentrated heat sources is critical. Despite being denser and more expensive than aluminum, copper's ability to rapidly spread and dissipate intense heat justifies its use in high-performance computing, power electronics, and other demanding systems where thermal throttling must be avoided at all costs.

Copper sets the standard for thermal performance in metals.

Thermal Conductivity: Exceptionally high, 380-400 W/(m·K) (pure copper C11000) – nearly double aluminum.

Density: High, around 8.96 g/cm³, making it significantly heavier.

Cost: More expensive than aluminum for raw material and machining.

Manufacturability: Good machinability, but more challenging than aluminum (machining, skived, stamped, forged, bonded fins).

Corrosion Resistance: Less resistant than aluminum; often requires plating (e.g., nickel).

CTE: Around 17 ppm/°C, a good match for silicon.

High-Performance Computing (CPUs, GPUs, FPGAs)

Power electronics (IGBT modules, EV inverters)

Laser diodes, medical equipment

Advantage | Disadvantage |

Highest thermal conductivity | High density (heavy) |

Excellent for high heat flux | Higher cost |

Good CTE match for silicon | Less corrosion resistant |

Copper is chosen when uncompromising thermal performance is essential for concentrated heat sources.

Graphite offers unique properties among heat sink materials, particularly for specialized needs.

Graphite heat sinks, particularly those made from Pyrolytic Graphite Sheet (PGS) or Graphite Foam, offer unique anisotropic thermal conductivity, meaning heat conducts exceptionally well along one plane while being an insulator in the perpendicular direction. This makes them ideal for specialized applications requiring ultra-lightweight, thin, and highly directional heat spreading, especially in compact electronics where traditional metals are too heavy or bulky, despite their higher cost and specific manufacturing challenges.

Graphite materials have distinct thermal characteristics.

Thermal Conductivity: Highly anisotropic. PGS: 700-1700 W/(m·K) in-plane, 5-15 W/(m·K) through-plane. Graphite Foam: 150-200 W/(m·K) (more isotropic).

Density: Extremely low (0.05 g/cm³ for foam, 2.2 g/cm³ for PGS). Ultra-lightweight.

Cost: Generally higher than aluminum and copper.

Manufacturability: PGS can be cut, laminated, bent. Graphite foam can be machined but is brittle.

Corrosion Resistance: Excellent chemical inertness.

CTE: Highly anisotropic, requiring careful design.

Portable electronics (smartphones, tablets, ultra-thin laptops as heat spreaders)

Wearable devices, aerospace

LED backlighting, specialized battery thermal management

Advantage | Disadvantage |

Ultra-lightweight | Anisotropic thermal conductivity |

Extremely high in-plane thermal conductivity | Brittle, low through-plane conductivity |

Excellent chemical inertness | Higher cost |

Graphite is ideal for niches where its unique directional heat spreading and ultra-low weight are critical.

Sometimes, combining heat sink materials offers the best solution.

Mixed composition heat sinks combine two or more materials to leverage their individual strengths, creating optimized thermal solutions that overcome the limitations of single-material designs. Common examples include copper-aluminum bonded heat sinks for efficient heat spreading and lightweight fin structures, or vapor chambers integrated with aluminum fins, offering superior heat transfer from hot spots while maintaining overall system weight and cost efficiency.

These compositions aim for a "best of both worlds" approach.

Copper Base with Aluminum Fins: Copper base for heat spreading, aluminum fins for lightweight dissipation. Manufacturing involves bonding (soldering, brazing, epoxy).

Vapor Chambers/Heat Pipes with Aluminum Fins: Copper vapor chambers/heat pipes move heat from hot spots to aluminum fin stacks for efficient dissipation.

Aluminum-Silicon Carbide (AlSiC) Composites: Silicon carbide in an aluminum matrix for tailored CTE (matching silicon) and higher stiffness, lower density than copper.

Graphite-Copper/Aluminum Composites: Combines graphite's in-plane conductivity with metal's structural integrity for lightweight, directional heat spreading.

Advantage | Disadvantage |

Optimized performance | Increased manufacturing complexity |

Reduced weight (vs. all-copper) | Potentially higher cost |

Improved cost-effectiveness | Interface thermal resistance |

Mixed compositions offer sophisticated thermal management by strategically combining materials.

A direct comparison of heat sink materials properties clarifies their differences.

A direct comparative analysis of heat sink materials reveals that copper offers the highest thermal conductivity, making it ideal for concentrated heat loads, while aluminum provides the best balance of cost, weight, and manufacturability for moderate applications. Graphite excels in anisotropic heat spreading for ultra-lightweight designs, and mixed compositions strategically combine these properties to overcome individual material limitations, with density and cost being critical differentiators across all options.

Here's a side-by-side comparison:

Property | Aluminum (e.g., 6063) | Copper (C11000) | Graphite (PGS) | AlSiC Composite |

Thermal Conductivity (W/m·K) | 180-220 | 380-400 | 700-1700 (in-plane) / 5-15 (through-plane) | 180-200 |

Density (g/cm³) | 2.7 | 8.96 | 2.2 | 3.0-3.1 |

CTE (ppm/°C) | 23 | 17 | Highly Anisotropic | 7-10 |

Relative Cost | Low | Medium-High | High | High |

Relative Weight | Low | High | Ultra-Low | Medium |

Thermal Conductivity: Copper leads for isotropic heat transfer. Graphite (PGS) for in-plane spreading.

Weight: Aluminum and graphite are lightest. Copper is heaviest.

Cost vs. Performance: Aluminum is best value. Copper is premium performance. Graphite and AlSiC are specialized, higher-cost.

CTE Matching: Copper and AlSiC are good for silicon.

The "best" heat sink material depends on balancing performance, weight, cost, and specific application needs.

The choice of heat sink material impacts manufacturing complexity, cost, and design flexibility.

Manufacturing considerations vary significantly across heat sink materials: aluminum excels in cost-effective extrusion for complex fin geometries, while copper is primarily machined or skived for high-performance designs despite higher material and processing costs. Graphite requires specialized handling for its brittle nature and anisotropic properties, often involving cutting and laminating. Mixed compositions introduce additional complexity through bonding or integration processes, demanding specialized techniques to ensure optimal thermal and mechanical interfaces.

KingKa Tech, with 15+ years of experience, manages these complexities.

Extrusion: Common, cost-effective for high volumes, good for linear fins.

Skived Fins: Creates thin, high-density fins from a solid block.

Bonded Fins: Allows for tall, thin fins, but adds interface resistance.

CNC Machining: For custom, high-precision designs.

CNC Machining: Primary method for precision and complex features.

Skived Fins: Possible, but more challenging than aluminum.

Forging: For high-density, complex shapes.

Cutting/Laminating (PGS): Simple for thin sheets, but brittle.

Machining (Graphite Foam): Possible, but requires careful handling.

Bonding/Brazing/Soldering: For joining different materials, critical for interface quality.

Sintering/Casting (AlSiC): Specialized processes for composites.

Integration: Complex assembly steps for robust interfaces.

KingKa Tech's 35 CNC machines and experienced team handle diverse heat sink material manufacturing.

Selecting heat sink materials involves weighing thermal performance against overall budget.

A comprehensive cost-benefit analysis for heat sink materials reveals that aluminum offers the best value for moderate thermal loads due to its low cost and excellent manufacturability. Copper, despite higher material and processing costs, provides superior thermal performance essential for high-power applications, justifying its expense through enhanced reliability and efficiency. Graphite and mixed compositions, while more costly, offer specialized benefits like ultra-lightweight or tailored CTE, making them cost-effective only when their unique properties are critical for application success.

Consider total cost of ownership, including manufacturing and performance gains.

Cost: Lowest raw material and manufacturing cost.

Benefit: Good performance for general applications at an affordable price. Lightweight.

Best When: Budget is primary, heat load is moderate.

Cost: Highest raw material and machining costs.

Benefit: Unmatched thermal conductivity, preventing throttling in high-power components, extending lifespan.

Best When: Thermal performance is non-negotiable for high-value, high-power density systems.

Cost: High.

Benefit: Ultra-lightweight, thin, exceptional in-plane heat spreading. Enables compact, innovative designs.

Best When: Weight and form factor are paramount, and unique anisotropic properties solve specific thermal challenges.

Cost: Higher than single-material aluminum, potentially comparable to copper.

Benefit: Tailored balance of properties, achieving near-copper performance at lower weight/cost, or specific CTE matching.

Best When: Single materials fail to meet all design requirements (performance, weight, cost).

The "best" heat sink material provides necessary performance and reliability at the lowest total cost of ownership.

Matching heat sink materials to specific application demands is crucial for success.

Matching heat sink materials to application needs is crucial: aluminum is ideal for general-purpose electronics with moderate heat loads where cost and weight are key. Copper is indispensable for high-power density components in servers and EVs requiring maximum heat transfer. Graphite suits ultra-lightweight, thin devices needing directional heat spreading. Mixed compositions provide tailored solutions for complex challenges, balancing performance, weight, and cost across diverse industries from consumer electronics to aerospace.

Here's a summary of material suitability:

Best For: Moderate heat loads (~150-200W), cost-sensitive products (consumer electronics, LED lighting), high-volume production.

Example: Desktop CPU cooler, LED street light.

Best For: High heat flux/power density (200W+), mission-critical systems (servers, data centers), direct die attach, liquid cold plates.

Example: High-end GPU, EV inverter IGBT module.

Best For: Ultra-thin/lightweight devices (smartphones, wearables), directional heat spreading, space-constrained applications.

Example: Smartphone heat spreader, drone thermal management.

Best For: Complex thermal challenges (high heat flux with weight constraints), CTE mismatch mitigation, extreme heat spreading.

Example: High-performance laptop cooler (vapor chamber + aluminum fins), IGBT power module (AlSiC base).

The optimal heat sink material is a strategic choice, balancing properties with application demands.

Choosing the right heat sink materials is fundamental for effective thermal management.

In conclusion, the strategic selection of heat sink materials—aluminum, copper, graphite, or mixed compositions—is paramount for achieving optimal thermal management. Aluminum offers a cost-effective, lightweight solution for moderate heat loads, while copper provides superior thermal conductivity for high-power density applications. Graphite excels in ultra-lightweight, anisotropic heat spreading for specialized needs, and mixed compositions leverage synergistic properties to overcome individual material limitations. A thorough understanding of each material's thermal conductivity, density, cost, and manufacturability, combined with a detailed application-specific cost-benefit analysis, is essential to make the most informed choice for thermal success.

Each heat sink material has unique advantages:

Aluminum: Cost-effective, lightweight, versatile for moderate loads.

Copper: Uncompromising performance for high-heat flux, high-power density.

Graphite: Ultra-lightweight, anisotropic heat spreading for specialized, compact designs.

Mixed Compositions: Engineered solutions for tailored performance, weight, and cost.

The "best" material depends on a holistic evaluation of thermal needs, weight, budget, and manufacturing. Informed decisions lead to robust, efficient, and reliable thermal management.

Need expert guidance for your heat sink material selection? KingKa Tech is your one-stop thermal solution provider, with 15+ years of experience in customized heat sinks and liquid cold plates. Our R&D team offers free technical design support, thermal analysis, and airflow simulations. Contact us today to ensure your thermal success!