Views: 89 Author: Site Editor Publish Time: 2023-04-10 Origin: Site

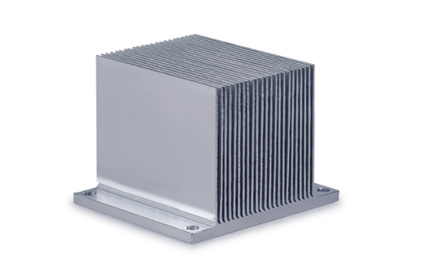

KINGKA specializes in the production of aluminum extrusion heat sink, led lighting heat sink, bonded fins heat sink, cnc machining parts and other products.

CNC machining refers to numerical control machining, which is a method that uses digital information to control mechanical motion and machining processes. Traditional mechanical processing is performed by manual operation of ordinary machine tools. During the processing, the mechanical cutter is used to cut the metal by hand, and the accuracy of the product is measured with a caliper and other tools by the eyes. However, traditional manual processing is far from meeting the production needs, so cnc rapid prototyping appears It provides the possibility for standardization, precision and efficiency of mechanical processing, and CNC processing also shines in the radiator industry.

Ordinary processing technology must have energy and complex procedures for quality, such as the selection of the cutting route, shape and size of the heat sink panel, and the intensity of processing on different materials is not the same, so in order to reduce errors in specific operations Then the efficiency must not be high. However, with CNC machining, all the processes are arranged and designed first, compiled into the processing program, streamlining the process and carrying out each step in an orderly manner, without affecting the efficiency due to human factors, and greatly improving the production efficiency of the manufacturer.

Nowadays, many businesses not only have high requirements for the heat dissipation performance of the aluminum heat sink, but also pursue the aesthetic appearance, and the use of CNC processing embossing seal can achieve compatibility between the two. The CNC processing quality is stable, the surface texture of the finished product is clear, the metal texture is strong, flat and smooth, no scratches, no missing corners, and the precision of the heat dissipation system of the raw material will not be changed under precision processing. The manufacturer can adjust the specific process in the process to enhance Its heat dissipation performance, such as oxidation, wire drawing, baking paint, sand blasting and other processes can be carried out under numerical control operation. With the help of CNC machining, only the programming needs to be set to process the desired profile, and the finished product is durable, precise and tight.

KINGKA, as a manufacturer with more than ten years of professional production of aluminum extrusion heat sink, has already mastered CNC machining parts and implemented it well in practice. It produces products with the most complete technology, provides quality services with the most rigorous attitude, and pursues the highest good.