Views: 121 Author: Site Editor Publish Time: 2025-10-15 Origin: Site

When choosing between copper vs. aluminum heat sinks, aluminum is generally more popular due to its cost-effectiveness, lighter weight, and ease of manufacturing, making it ideal for most applications. However, copper offers superior thermal conductivity, making it the preferred choice for high-performance, compact, or high-heat-flux applications where maximum heat dissipation is critical, despite its higher cost and density.

Electronic devices, from tiny consumer gadgets to powerful server CPUs and GPUs, generate a lot of heat. To keep these components cool and ensure their longevity, heat sinks play a crucial role. You've probably noticed that most heat sinks are made of aluminum, but copper is also a common choice, especially in high-performance scenarios. This naturally leads to a big question: "If copper is a better heat conductor, why is aluminum so much more common?" It's a fantastic question, and the answer isn't as simple as "one is better than the other." Instead, it's about balancing various factors like performance, cost, weight, and manufacturing feasibility. Let's dive deep into the world of copper vs. aluminum heat sinks to help you understand which material is the best fit for your specific thermal management challenges.

Before we compare the materials, let's quickly clarify what heat sinks do and why the material choice is so critical.

Heat sinks are essential components in electronic devices that absorb and dissipate heat from high-temperature parts like CPUs, LEDs, and power transistors, preventing overheating and prolonging their lifespan. The material chosen for a heat sink significantly impacts its cost, durability, and thermal performance, making the selection crucial for optimal heat dissipation and overall system efficiency.

A heat sink is essentially a passive heat exchanger that transfers heat generated by an electronic or mechanical device to a fluid medium, typically air or a liquid coolant. By increasing the surface area exposed to the cooling medium, heat sinks facilitate more efficient heat dissipation, preventing components from reaching damaging temperatures. They are often made of metals like copper or aluminum and feature fins or pins to maximize this surface area.

Heat sinks come in two main forms:

Active Heat Sinks: These use fans or blowers for forced cooling, actively moving air over the fins.

Passive Heat Sinks: These rely on natural convection, where warmer air rises and cooler air sinks, creating a natural airflow.

Regardless of the type, their fundamental purpose is to limit overheating and extend the operational life of electronic parts.

The choice of material for a heat sink is paramount because it directly influences several critical factors:

Thermal Conductivity: This is the material's ability to conduct heat. A higher thermal conductivity means heat can be transferred away from the component more quickly and efficiently.

Weight: For portable devices, automotive systems, or aerospace applications, a lighter heat sink is often preferred.

Cost: The raw material cost and manufacturing complexity significantly impact the final price of the heat sink, affecting the overall budget of a project.

Durability and Corrosion Resistance: The material needs to withstand its operating environment without degrading, ensuring a long service life.

Manufacturing Feasibility: How easily the material can be shaped into complex designs (like fins or microchannels) affects production methods and costs.

These factors highlight why selecting the best heat sink material is a crucial decision in thermal management.

When comparing copper vs. aluminum heat sinks, several key properties stand out, each offering distinct advantages and disadvantages.

Comparing copper vs. aluminum heat sinks reveals that copper boasts superior thermal conductivity (around 400 W/m·K), making it excellent for high-heat applications, but it's significantly heavier and more expensive. Aluminum, with good thermal conductivity (136-205 W/m·K), is much lighter, more affordable, and easier to machine, making it the most popular choice for general applications where cost and weight are critical.

This is often the first property people consider when thinking about heat sinks.

Copper Heat Sinks: Copper has exceptional thermal conductivity, typically ranging from 390 to 400 W/m·K. This is about 50% higher than aluminum, meaning copper can transfer and dissipate heat very fast. Its superior heat transfer property allows it to distribute heat equally throughout its entire surface. This makes copper ideal for applications with high and constant heat generation.

Aluminum Heat Sinks: Aluminum offers good thermal conductivity, with alloys like 6061 or 6063 typically ranging from 136 to 205 W/m·K. While lower than copper, it's still efficient enough for many applications. Aluminum heat sinks often compensate for this lower conductivity through optimized designs and larger surface areas to maintain good heat dissipation.

Verdict: Copper is the clear winner for raw heat transfer capability.

Weight is a significant factor, especially for portable or weight-sensitive applications.

Copper Heat Sinks: Copper is much denser, with a density of 8.9 g/cm³. This makes copper heat sinks significantly heavier. While more weight can sometimes be good for stability, it often limits copper's use in mobile or weight-sensitive applications.

Aluminum Heat Sinks: Aluminum is a lightweight metal with a density of only 2.7 g/cm³, which is about one-third that of copper. This makes aluminum an excellent choice when weight reduction is necessary.

Verdict: Aluminum wins for lightweight applications.

Cost is almost always a major consideration in any project.

Copper Heat Sinks: Copper is considerably more expensive than aluminum, often costing around three times as much. This higher cost means copper is typically chosen only when maximum heat removal is absolutely essential and budget is less of a concern.

Aluminum Heat Sinks: Aluminum is much more affordable, with its price per metric ton being about one-third that of copper. This cost-effectiveness is a primary reason for its widespread popularity.

Verdict: Aluminum is the more budget-friendly option.

The ability to resist corrosion ensures the heat sink's longevity and consistent performance.

Copper Heat Sinks: Copper heat sinks are very durable and corrosion-resistant, especially in humid or harsh conditions, due to copper's chemical stability. They work steadily and last longer.

Aluminum Heat Sinks: Aluminum naturally forms a protective oxide layer when exposed to air, which provides good corrosion resistance for most environmental conditions. However, this resistance might not be sufficient in highly alkaline or acidic environments. Anodizing can increase the thickness of this oxide layer, further improving corrosion protection and aesthetics.

Verdict: Both offer good corrosion resistance, but copper generally has superior chemical stability in harsher conditions.

Specific heat capacity refers to how much heat energy a material can absorb before its temperature increases.

Copper Heat Sinks: Copper has a lower specific heat capacity (around 385 J/kg·K). This means it heats up faster than aluminum. However, its higher thermal conductivity allows it to quickly transfer that heat away from the source. This makes copper better for applications with high and constant heat generation, where rapid heat removal is key.

Aluminum Heat Sinks: Aluminum has a higher specific heat capacity (around 900 J/kg·K). This means it can absorb more heat energy before its temperature significantly rises. Aluminum heat sinks work well in applications with ordinary or fluctuating heat loads, where they can act as a thermal buffer.

Verdict: Copper excels at rapid heat transfer, while aluminum is better at absorbing and holding heat.

In some specialized applications, electrical conductivity is also a factor.

Copper Heat Sinks: Copper is an excellent electrical conductor, superior to aluminum. If an application requires both electrical and heat conduction, such as in RF equipment or power electronics, copper is often the better choice.

Aluminum Heat Sinks: Aluminum also conducts electricity well, though not as efficiently as copper. For most heat sink applications, this difference isn't significant, but it might be considered if the design needs electrical shielding or grounding.

Verdict: Copper has superior electrical conductivity, which can be a bonus in specific applications.

The material choice also heavily influences how a heat sink can be manufactured and the complexity of its design.

Manufacturing copper vs. aluminum heat sinks shows aluminum is much easier to machine, particularly with CNC and extrusion, allowing for intricate designs and high-volume production. Copper, being harder and prone to work-hardening, is more challenging to machine and cannot be extruded, requiring specialized tools and precision techniques, which increases manufacturing costs and energy consumption.

The ease with which a material can be shaped is crucial for production efficiency and design flexibility.

Aluminum Heat Sinks: Aluminum is considerably easier to machine, especially with CNC and extrusion processes. Its softness allows manufacturers to create thin profiles and intricate fins without excessive tool wear, making it ideal for complex cooling designs and high-volume production. Common manufacturing methods include extrusion, stamping, and CNC machining. Extruded aluminum heat sinks are particularly popular for their cost-effectiveness and ability to meet the needs of most projects.

Copper Heat Sinks: Machining copper is more challenging due to its hardness and tendency to work-harden. Copper cannot be extruded. It requires special tools, precision machining, and more energy during manufacturing. This complexity means that experienced manufacturers are needed to produce copper heat sinks for demanding applications.

Verdict: Aluminum offers greater manufacturing flexibility and ease, especially for complex geometries and mass production.

The appearance and protective coatings can also differentiate the two materials.

Aluminum Heat Sinks: Aluminum heat sinks can be anodized in various colors, which not only improves their appearance but also enhances corrosion resistance. This customization is particularly useful in consumer electronics where both durability and aesthetics matter.

Copper Heat Sinks: Copper has a natural reddish-brown color, but its visual customization options are more limited. While surface treatments can reduce copper's oxidation, visual customization is generally not a priority for copper heat sinks.

Verdict: Aluminum offers more aesthetic versatility through anodizing.

Sustainability is an increasingly important factor in material selection.

Copper Heat Sinks: While copper is recyclable, its recycling process generally uses more energy compared to aluminum recycling. It also has a lower recycling rate, and its mining has a larger environmental footprint, making copper heat sinks collectively less sustainable.

Aluminum Heat Sinks: Aluminum is highly recyclable, and its recycling process saves up to 95% of the energy compared to primary production. Aluminum retains its properties even after multiple recycling cycles. Being lighter and abundantly available also reduces transportation and environmental impact.

Verdict: Aluminum has a lower carbon footprint and is more environmentally friendly due to easier and more energy-efficient recycling.

Given their distinct properties, copper vs. aluminum heat sinks find their optimal use in different applications.

Copper heat sinks are the go-to choice for high-performance computing, power electronics, electric vehicles, and telecom infrastructure, where maximum heat dissipation and reliability are paramount. In contrast, aluminum heat sinks are widely used in LED lighting, automotive systems, consumer electronics, and industrial equipment due to their affordability, lightweight nature, and versatility.

Copper heat sinks are typically reserved for applications where their superior thermal conductivity is absolutely critical, and the higher cost and weight are acceptable trade-offs.

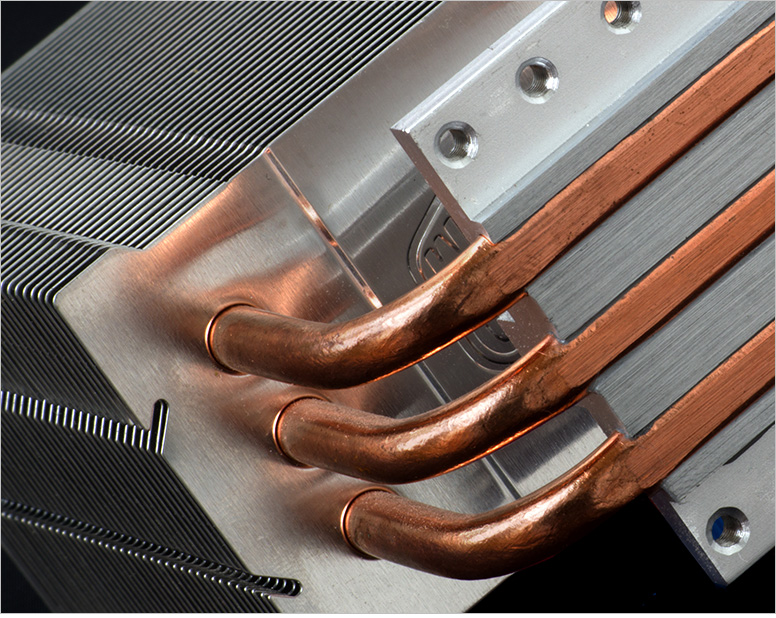

High-Performance Computing (HPC): In AI clusters and supercomputers, CPUs and GPUs generate immense heat. Copper heat sinks, especially those utilizing advanced technologies like skived fin technology, can achieve maximum heat dissipation per unit volume, making them ideal for high-end chips and servers.

Power Electronics: Devices like inverters, rectifiers, and motor controllers generate significant heat. Copper's ability to quickly transfer and dissipate this heat ensures the reliability and longevity of these critical components.

Electric Vehicles (EVs): In EV power systems, efficient cooling of batteries and power inverters is crucial for performance and safety. Copper heat sinks provide the necessary thermal management.

Telecom Infrastructure: Base stations and network equipment often operate in demanding conditions with high heat loads. Copper heat sinks ensure stable operation and extended lifespan.

These applications prioritize reliability and maximum heat dissipation, making copper the preferred choice.

Aluminum heat sinks are the most popular choice for a vast array of applications due to their excellent balance of performance, cost, and weight.

LED Lighting: Aluminum heat sinks are widely used in LED luminaires to dissipate heat from the LED chips, ensuring their efficiency and long lifespan. Their lightweight nature is also beneficial for fixture design.

Consumer Electronics: From desktop computers to gaming consoles and televisions, aluminum heat sinks are prevalent due to their cost-effectiveness and ability to be easily manufactured into various shapes.

Automotive Systems: In various automotive electronic control units (ECUs) and infotainment systems, aluminum heat sinks provide reliable cooling while keeping weight down.

Industrial Equipment: Many industrial control systems, power supplies, and automation components utilize aluminum heat sinks for their robust and affordable thermal management.

Photovoltaic Industry: Aluminum skived heat sinks are widely used in inverters for solar power systems.

Aluminum's versatility, affordability, and lightweight properties make it the go-to choice for most projects.

The choice isn't always strictly copper vs. aluminum heat sinks. Sometimes, the best solution involves combining their strengths or exploring entirely new materials.

Hybrid heat sinks combine copper's superior thermal conductivity with aluminum's lightweight and cost-effectiveness, often using a copper base for direct heat absorption and aluminum fins for broader dissipation. Beyond these, advanced materials like CarbAl (a carbon-aluminum composite) and natural graphite composites are emerging, offering ultra-high thermal conductivity with reduced weight, pushing the boundaries of thermal management solutions.

To leverage the advantages of both materials, hybrid heat sinks have emerged as an effective solution.

Copper-Embedded Technology: This approach involves using a copper base directly in contact with the heat source (like a CPU or GPU) to rapidly absorb and transfer a large amount of heat. This copper base is then tightly combined with an aluminum extruded heat sink, which efficiently spreads the heat to a larger surface area for dissipation, often aided by a fan. This harmonious combination utilizes copper's fast heat conduction and strong heat absorption with aluminum's light density, cheap price, and convenient mass production.

Bonded Copper and Aluminum: Some manufacturers bond copper and aluminum together, typically with a copper plate for high thermal conductivity surrounded by aluminum for its lightweight properties. However, the effectiveness of these designs relies heavily on a tight bond between the two metals; a poor bond can actually do more harm than good.

Hybrid designs offer a balanced solution for cost and performance, especially in applications requiring high heat dissipation without the full weight and cost penalty of an all-copper solution.

Beyond traditional metals, research and development are constantly exploring new materials for even better thermal management.

CarbAl: In 2008, Applied Nanotech announced CarbAl, an isotropic material composed of 20% aluminum and 80% carbon-derived materials. CarbAl boasts a thermal conductivity of 425 W/mK (even higher than copper) and a density similar to aluminum, effectively offering the best of both worlds.

Natural Graphite Composites: These materials are gaining popularity, offering thermal conductivity close to copper (around 370 W/mK) but with a significant weight advantage, weighing only about 70% of aluminum.

Graphene-based Heat Sinks: Graphene offers ultra-high thermal conductivity, making it a promising material for future heat sink designs.

Carbon Composites: These are lightweight materials with excellent heat dissipation properties.

Phase Change Materials (PCMs): PCMs store and release heat efficiently by changing their state (e.g., melting and solidifying), offering a unique approach to thermal management.

These advanced materials represent the future of heat sink technology, pushing the boundaries of what's possible in heat dissipation.

The ultimate decision between copper vs. aluminum heat sinks isn't about which material is inherently "better," but which is best suited for your specific application requirements.

Choosing between copper vs. aluminum heat sinks depends entirely on your application's specific needs: copper is superior for compact, high-functionality systems demanding maximum heat dissipation due to its nearly double thermal conductivity. Aluminum, being cheaper and lighter, is ideal for applications where cost, weight, and ease of manufacturing are key factors, such as in consumer electronics or LED lighting.

Here's a quick guide to help you decide:

Choose Aluminum if:

Cost is a primary concern: Aluminum is significantly more affordable.

Weight is critical: For portable devices, automotive, or aerospace applications, aluminum's low density is a major advantage.

Ease of manufacturing complex shapes is needed: Aluminum is easily extruded and machined, allowing for intricate designs and high-volume production.

Your application has moderate or fluctuating heat loads: Aluminum's higher specific heat capacity can absorb more heat before its temperature rises significantly.

Environmental impact is a consideration: Aluminum is more energy-efficient to recycle and has a lower carbon footprint.

Choose Copper if:

Maximum heat dissipation is paramount: For high-power or compact systems, copper's superior thermal conductivity (nearly double that of aluminum) is unmatched.

Space is extremely limited: Copper's efficiency allows for smaller heat sinks to dissipate the same amount of heat as larger aluminum ones.

Reliability in harsh or humid conditions is essential: Copper offers excellent corrosion resistance and chemical stability.

Electrical conductivity is also a requirement: In certain power electronics or RF equipment, copper's electrical properties are beneficial.

Your application has high and constant heat generation: Copper can quickly transfer away large amounts of heat.

For many applications, aluminum remains the best heat sink material due to its excellent balance of performance and cost. However, if your project demands maximum efficiency and can justify the investment, copper may be worth it. And don't forget hybrid solutions, which can offer a balanced approach.

The debate of copper vs. aluminum heat sinks isn't about finding a single "best" material, but rather understanding the unique strengths of each and aligning them with your specific project needs. Both metals are indispensable in thermal management, each playing a vital role in keeping our electronics cool and reliable.

In conclusion, aluminum heat sinks offer advantages in cost, weight, and manufacturing versatility, making them ideal for most applications, while copper heat sinks excel in thermal conductivity, making them superior for demanding, high-heat situations. The best choice ultimately depends on your project's specific requirements, balancing performance, budget, and physical constraints.

Aluminum's affordability, lightweight nature, and ease of manufacturing make it the popular choice for a vast range of applications, from consumer electronics to LED lighting. Copper, with its unparalleled thermal conductivity, is the champion for high-performance computing, power electronics, and other compact, high-heat-flux environments where every watt of heat dissipation counts. Hybrid solutions and advanced materials are also pushing the boundaries, offering even more tailored options for complex thermal management challenges.

Need a custom heat sink designed exactly to your needs? Don't compromise on your thermal solution. Whether you require the cost-effectiveness of aluminum, the superior performance of copper, or a hybrid design, KingKa Tech has over 15 years of experience in providing high-quality, customized liquid cold plates, heat sinks, and precision CNC machining services. Contact us today to discuss your project and get expert guidance on selecting the perfect material and design for your heat sink!