| Availability: | |

|---|---|

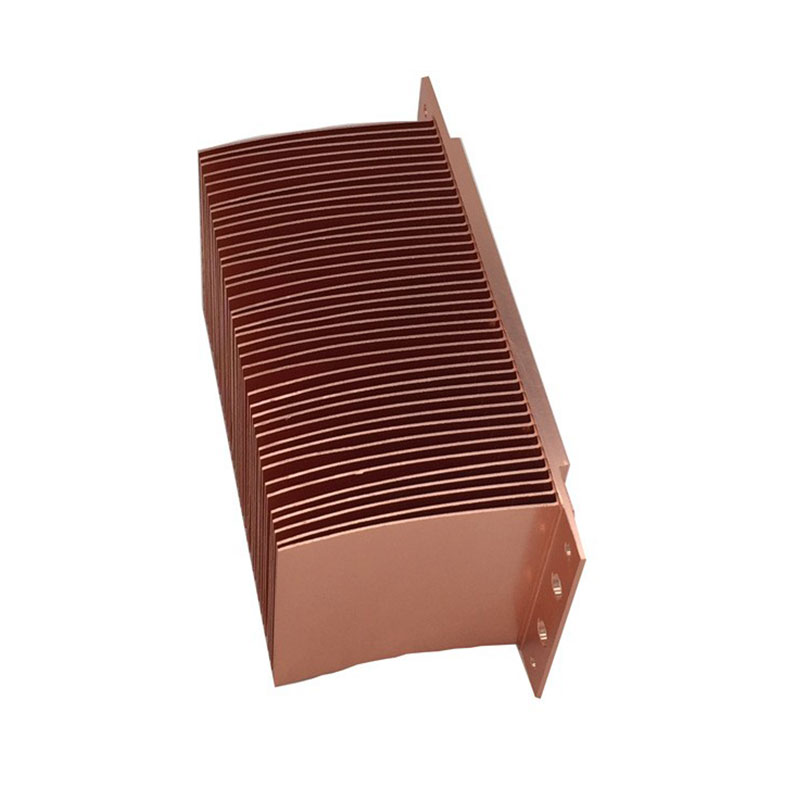

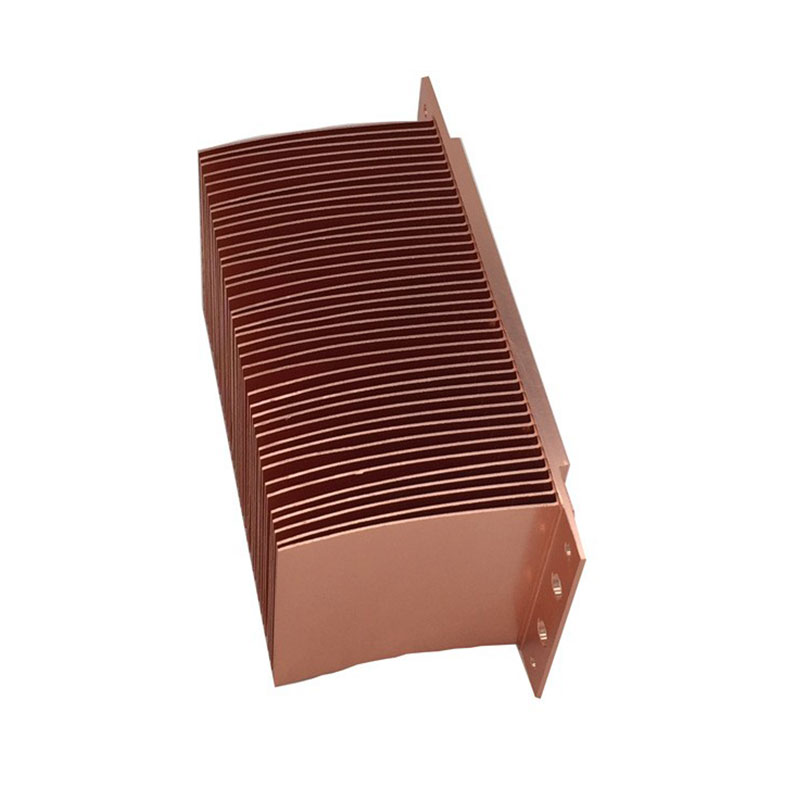

At KingKa, we are committed to delivering innovative thermal solutions that meet the evolving demands of modern technology. Our Pure Copper Skived Fin Heat Sink with CNC Machining is engineered to provide superior cooling for high-power electronics, ensuring reliability in compact and heat-intensive environments. With over 15 years of expertise and state-of-the-art manufacturing, we offer a customizable, high-performance heat sink that stands out in the industry.

Superior Thermal Conductivity: Made from pure copper, this heat sink offers exceptional thermal conductivity (~400 W/mK), ensuring rapid heat transfer from components like LEDs, power ICs, and inverters.

Skived Fin Technology: The skived fin process creates high-density, ultra-thin fins (as thin as 0.05 mm), maximizing surface area for efficient heat dissipation in compact spaces.

Precision CNC Machining: With tolerances as tight as ±0.05 mm, our 35 high-end CNC machines ensure precise manufacturing for a perfect fit and optimal performance.

Fully Customizable: Tailor dimensions, fin thickness, height, and gap to meet your specific needs, making it ideal for unique applications.

Cost-Effective Production: The skiving process eliminates expensive tooling costs, offering flexibility for prototyping and high-volume production.

Corrosion Resistance: Finished with passivation to protect against corrosion, ensuring durability in harsh environments.

Feature | Specification |

|---|---|

Material | Pure Copper |

Fin Type | Skived Fin |

Fin Thickness | 0.05 mm - 3 mm |

Fin Height | Up to 120 mm |

Fin Gap | 0.2 mm - 6.5 mm |

Base Thickness | 1 mm - 30 mm |

Overall Size | Customizable (e.g., 220 x 150 x 35 mm) |

Tolerance | ±0.05 mm |

Finish | Passivation |

Applications | LED Lighting, Power Electronics, Telecommunications, Industrial Equipment |

The KingKa Pure Copper Skived Fin Heat Sink efficiently manages heat through a two-step process:

Heat Transfer: The copper base absorbs heat from high-power components, such as LED modules or power transistors, leveraging copper’s high thermal conductivity.

Heat Dissipation: The skived fins, with their high-density design, increase surface area, allowing heat to dissipate into the surrounding air via convection. This is enhanced by airflow from fans or natural convection, making it ideal for active cooling systems.

This heat sink is versatile and excels in a range of high-power applications:

High-Power LED Lighting: Ensures consistent brightness and extends LED lifespan by preventing overheating.

Power Electronics: Cools inverters, converters, and power ICs in UPS systems and wind power converters.

Telecommunications: Maintains reliable operation in base stations and networking equipment.

Industrial Equipment: Provides robust cooling for control systems and machinery in harsh environments.

Proven Expertise: Over 15 years of experience in thermal management solutions, backed by a dedicated R&D team with more than 25 years of expertise in machining and thermal engineering.

Advanced Manufacturing: Our 35 high-end CNC machines deliver precision and consistency, ensuring high-quality products tailored to your needs.

Quality Assurance: ISO9001:2008 certified, with rigorous four-stage inspections to guarantee defect-free heat sinks.

Customer-Centric Support: We offer online technical support, thermal design consultation, and a 1-year quality guarantee, with return and replacement options for any quality issues.

Global Reach: Serving clients across the USA, Europe, and Asia, we deliver reliable solutions worldwide with samples available in 15 days and mass production in 25-30 days.

At KingKa, we are committed to delivering innovative thermal solutions that meet the evolving demands of modern technology. Our Pure Copper Skived Fin Heat Sink with CNC Machining is engineered to provide superior cooling for high-power electronics, ensuring reliability in compact and heat-intensive environments. With over 15 years of expertise and state-of-the-art manufacturing, we offer a customizable, high-performance heat sink that stands out in the industry.

Superior Thermal Conductivity: Made from pure copper, this heat sink offers exceptional thermal conductivity (~400 W/mK), ensuring rapid heat transfer from components like LEDs, power ICs, and inverters.

Skived Fin Technology: The skived fin process creates high-density, ultra-thin fins (as thin as 0.05 mm), maximizing surface area for efficient heat dissipation in compact spaces.

Precision CNC Machining: With tolerances as tight as ±0.05 mm, our 35 high-end CNC machines ensure precise manufacturing for a perfect fit and optimal performance.

Fully Customizable: Tailor dimensions, fin thickness, height, and gap to meet your specific needs, making it ideal for unique applications.

Cost-Effective Production: The skiving process eliminates expensive tooling costs, offering flexibility for prototyping and high-volume production.

Corrosion Resistance: Finished with passivation to protect against corrosion, ensuring durability in harsh environments.

Feature | Specification |

|---|---|

Material | Pure Copper |

Fin Type | Skived Fin |

Fin Thickness | 0.05 mm - 3 mm |

Fin Height | Up to 120 mm |

Fin Gap | 0.2 mm - 6.5 mm |

Base Thickness | 1 mm - 30 mm |

Overall Size | Customizable (e.g., 220 x 150 x 35 mm) |

Tolerance | ±0.05 mm |

Finish | Passivation |

Applications | LED Lighting, Power Electronics, Telecommunications, Industrial Equipment |

The KingKa Pure Copper Skived Fin Heat Sink efficiently manages heat through a two-step process:

Heat Transfer: The copper base absorbs heat from high-power components, such as LED modules or power transistors, leveraging copper’s high thermal conductivity.

Heat Dissipation: The skived fins, with their high-density design, increase surface area, allowing heat to dissipate into the surrounding air via convection. This is enhanced by airflow from fans or natural convection, making it ideal for active cooling systems.

This heat sink is versatile and excels in a range of high-power applications:

High-Power LED Lighting: Ensures consistent brightness and extends LED lifespan by preventing overheating.

Power Electronics: Cools inverters, converters, and power ICs in UPS systems and wind power converters.

Telecommunications: Maintains reliable operation in base stations and networking equipment.

Industrial Equipment: Provides robust cooling for control systems and machinery in harsh environments.

Proven Expertise: Over 15 years of experience in thermal management solutions, backed by a dedicated R&D team with more than 25 years of expertise in machining and thermal engineering.

Advanced Manufacturing: Our 35 high-end CNC machines deliver precision and consistency, ensuring high-quality products tailored to your needs.

Quality Assurance: ISO9001:2008 certified, with rigorous four-stage inspections to guarantee defect-free heat sinks.

Customer-Centric Support: We offer online technical support, thermal design consultation, and a 1-year quality guarantee, with return and replacement options for any quality issues.

Global Reach: Serving clients across the USA, Europe, and Asia, we deliver reliable solutions worldwide with samples available in 15 days and mass production in 25-30 days.