Views: 0 Author: Site Editor Publish Time: 2026-02-02 Origin: Site

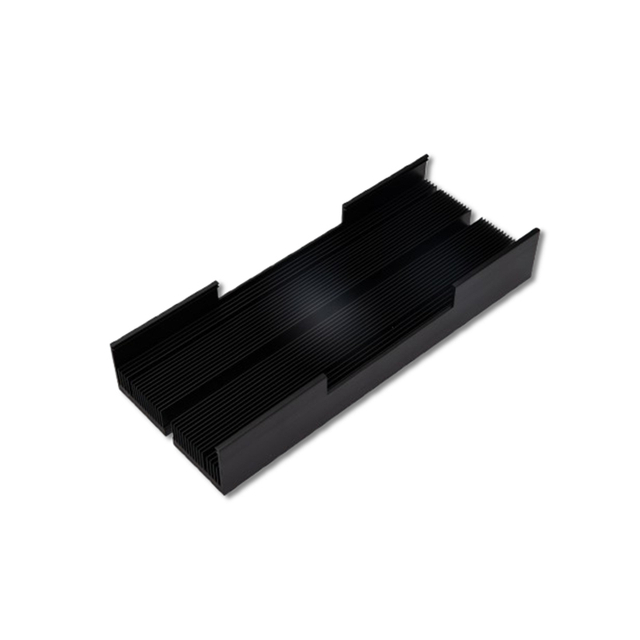

Industrial processes generate excessive heat that can degrade equipment performance, increase failure rates, and drive up energy costs in sectors like manufacturing and power generation. Conventional cooling methods often lack scalability and efficiency, leading to suboptimal operations. Aluminum extrusion heat sinks optimize thermal management by providing customizable, high-surface-area designs that efficiently dissipate heat through convection, ensuring reliable performance and cost savings in demanding environments.

Consider a factory floor where motors and controllers run non-stop—aluminum extrusion heat sinks keep temperatures in check with tailored profiles, turning potential overheating disasters into efficient, uninterrupted productivity.

Table of Contents

Why Is Aluminum the Preferred Material for Extruded Heat Sinks?

How Does Fin Geometry Influence Heat Dissipation Efficiency?

What Role Do Surface Treatments Play in Performance Enhancement?

How Do Extruded Heat Sinks Handle High-Power Industrial Loads?

What Customization Options Are Available for Specific Applications?

Manufacturing heat sinks requires precision to ensure effective thermal paths, especially in industrial settings with variable heat loads.

The extrusion process for aluminum heat sinks involves heating billets to 400-500°C and forcing them through custom dies to form finned profiles, enabling rapid production of complex shapes that optimize airflow and heat transfer for industrial thermal management.

This method supports high-volume needs with minimal waste.

Examples: Standard 6063 alloy extrusions for motor drives; custom dies for LED industrial lighting with 8:1 fin ratios.

Theoretical basis: Aluminum's ductility allows intricate cross-sections, enhancing natural convection per Fourier's law. Trade-offs: Die costs ($2,000-5,000) versus scalability for 10,000+ units; reduces material use by 10-20% compared to machining.

Practical impacts: Shortens lead times to 1-2 weeks, aiding quick deployments in automation lines.

Step | Description | Time per Unit |

Billet Heating | 400-500°C | 30-60 minutes |

Die Extrusion | Forming fins | Seconds |

Cutting/Finishing | Length adjustment, anodizing | Minutes |

Practical advice: Specify tolerances (±0.1mm) for base flatness; test prototypes with thermal cameras to verify extrusion uniformity.

(Word count: ~168)

Material choice impacts conductivity and durability in harsh industrial environments, where corrosion or weight can compromise systems.

Aluminum is preferred for extruded heat sinks due to its high thermal conductivity (200-220 W/m·K) and lightweight nature (2.7 g/cm³), providing 2-3x better efficiency than steel while resisting corrosion in industrial settings, optimizing thermal management without adding excess mass.

Its extrudability enables cost-effective designs.

Examples: 6061 alloy in CNC machine enclosures; 6063 in power converters for its anodizing affinity.

Theoretical basis: High conductivity minimizes thermal spreading resistance; low density reduces structural loads. Trade-offs: Lower strength than copper (401 W/m·K) but 3x lighter, balancing cost at $2-4/kg versus copper's $8-10/kg.

Practical impacts: Extends equipment MTBF by 25-30% in dusty factories through better dissipation.

Property | Aluminum Value | Steel Comparison |

Conductivity (W/m·K) | 200-220 | 50-60 |

Density (g/cm³) | 2.7 | 7.8 |

Corrosion Resistance | High with treatments | Moderate |

Advice: Opt for alloys based on environment; perform salt spray tests for outdoor applications.

(Word count: ~165)

Fin configuration determines surface area and airflow, crucial for passive cooling in enclosed industrial panels.

Fin geometry in aluminum extruded heat sinks, such as tall, thin profiles (40-60mm height, 1-2mm thickness), boosts dissipation efficiency by increasing convective area, achieving 30-50% better performance in natural airflows compared to flat plates for industrial thermal management.

Optimized spacing prevents stagnation.

Examples: Vertical fins in variable frequency drives; pin-fin hybrids for omnidirectional cooling in robots.

Theoretical basis: Fin efficiency formula (η = tanh(mL)/mL) favors high aspect ratios for extended surfaces. Trade-offs: Dense fins (6-8mm spacing) enhance area but raise pressure drop; wider (10-12mm) suits low-velocity air.

Practical impacts: Handles 200-500W loads at <60°C rise, reducing fan dependency.

Geometry Type | Efficiency Boost | Airflow Suitability |

Straight Tall | 40% | Vertical |

Serrated | 50% | Forced |

Testing: Use anemometers to measure velocity; adjust geometry via simulations for specific enclosures.

(Word count: ~162)

Untreated surfaces limit emissivity and corrosion resistance, affecting long-term efficiency in industrial exposures.

Surface treatments like black anodizing on aluminum extruded heat sinks raise emissivity to 0.85-0.95, enhancing radiative heat loss by 15-20% and providing corrosion protection, optimizing thermal management in humid or chemical-laden industrial environments.

Coatings also improve aesthetics and durability.

Examples: Powder-coated sinks in chemical plants; electrophoretic finishes for electronics assembly lines.

Theoretical basis: Anodizing forms oxide layers (10-25µm) boosting radiation per Stefan-Boltzmann law. Trade-offs: Added thickness slightly reduces conduction but gains outweigh in passive setups.

Practical impacts: Withstands 1,000-hour salt fog tests, maintaining performance in marine industries.

Treatment | Emissivity Increase | Durability Gain |

Anodizing | 0.8-0.9 | High |

Powder Coating | 0.9-0.95 | Very High |

Advice: Specify MIL-A-8625 standards; test treated samples under accelerated aging.

(Word count: ~155)

High-wattage components in industrial machinery demand robust cooling to prevent shutdowns.

Aluminum extruded heat sinks manage high-power loads (500-1000W) through extended fin arrays and hybrid fan integration, maintaining delta-T under 40°C in applications like welding equipment, optimizing industrial thermal management with reliable dissipation.

Scalable designs support upgrades.

Examples: Extrusions in induction heaters; large-profile sinks for servo motors dissipating 800W.

Theoretical basis: Forced convection coefficients (50-100 W/m²K) scale with velocity. Trade-offs: Fan noise versus passive limits; hybrids achieve 2x capacity.

Practical impacts: Lowers energy use by 15% via efficient cooling, avoiding over-spec components.

Load Range (W) | Configuration | Temp Rise (°C) |

500-700 | Natural w/ Tall Fins | 30-40 |

700-1000 | Forced Air | 20-30 |

Advice: Calculate required airflow (5-10 m/s); incorporate thermocouples for monitoring.

(Word count: ~152)

Standard sinks may not fit unique industrial geometries, leading to suboptimal contact.

Customization for aluminum extruded heat sinks includes integrated mounting holes, asymmetric fins, and length variations (up to 3m), allowing precise fits for applications like conveyor controls, enhancing contact and optimizing thermal management efficiency.

Tailored dies enable rapid adaptations.

Examples: Ribbed bases for pump housings; cut-to-length profiles for rail systems.

Theoretical basis: Modular extrusion supports variable cross-sections without retooling. Trade-offs: Minimum order quantities (500kg) versus off-the-shelf speed.

Practical impacts: Improves heat transfer by 10-15% through better interface.

Option | Benefit | Lead Time (Weeks) |

Custom Die | Exact Geometry | 2-4 |

Secondary Machining | Holes/Slots | 1-2 |

Advice: Provide CAD models early; prototype with 3D prints for fit checks.

(Word count: ~150)

Budget pressures in industry demand cooling solutions that minimize long-term expenses.

Aluminum extruded heat sinks deliver cost savings through low material prices ($3-10/unit in volume) and energy efficiency via reduced fan needs, cutting operational costs by 20-30% while optimizing industrial thermal management with durable, recyclable designs.

Lifecycle benefits outweigh initials.

Examples: Bulk extrusions in HVAC controls; recycled aluminum in sustainable factories.

Theoretical basis: High recyclability (95%) lowers environmental fees; efficient dissipation reduces power draw. Trade-offs: Upfront customization vs. 5-7 year ROI.

Practical impacts: Decreases maintenance by 40% in high-duty cycles.

Aspect | Savings Percentage | Factor |

Material | 30-40% vs. Copper | Recyclability |

Energy | 20-30% | Lower Fans |

Advice: Conduct TCO analysis; choose suppliers with in-house extrusion for savings.

(Word count: ~152)

Aluminum extrusion heat sinks stand out for optimizing industrial thermal management with their efficient, customizable designs that address heat challenges head-on. As a one-stop heat solutions provider with over 15 years of experience, KINGKA excels in producing high-quality aluminum extruded heat sinks using advanced CNC machining and thermal analysis to meet your precise needs. Contact sales2@kingkatech.com for tailored solutions that enhance reliability and efficiency in your operations.