Views: 17 Author: Site Editor Publish Time: 2025-08-04 Origin: Site

Are you facing issues like overheating, system crashes, or reduced device lifespan due to poor thermal performance? You're not alone. Many engineers and product designers struggle to manage heat in high-power electronics. Extruded aluminum heat sinks offer an efficient and economical thermal management solution, effectively transferring heat away from sensitive components to maintain stable operation, extend service life, and enhance overall performance.

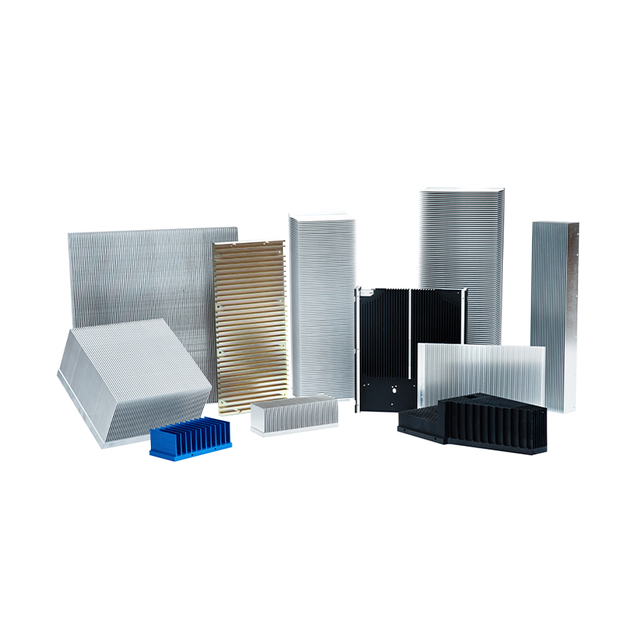

Extruded aluminum heat sinks are essential for your designs because they combine excellent heat dissipation, lightweight structure, and cost efficiency. Aluminum’s superior thermal conductivity allows for fast heat transfer, while extrusion enables customizable shapes and fins that maximize surface area for optimal cooling. Whether used in power electronics, LEDs, or industrial systems, extruded aluminum heat sinks ensure consistent performance, reliability, and design flexibility — making them indispensable in modern electronic thermal management.

Are you wondering what makesextruded aluminum heat sinksa go-to solution for thermal management? This section clarifies their fundamental nature and purpose.

An extruded aluminum heat sink is a passive heat exchanger made by pushing a heated aluminum billet through a shaped die, creating a profile with fins that maximize surface area for heat dissipation. Its primary function is to transfer thermal energy from a hot electronic component to the surrounding air or a liquid cooling system, preventing overheating and ensuring the component's stable operation and extended lifespan.

This solution is particularly valuable for MOSFET heat sinks and other high-power semiconductors. The extrusion process allows intricate fin geometries that increase the surface area available for convection, crucial for efficient heat transfer. It's cost-effective for high-volume production and allows complex, custom profiles tailored to specific thermal requirements.

Choosing the right material is key for your aluminum heat sink design. Why does aluminum consistently outperform other options for most applications?

Aluminum offers an excellent balance of thermal conductivity, low density, cost-effectiveness, and ease of manufacturing. While copper has higher thermal conductivity, aluminum's superior strength-to-weight ratio, lower cost, and extrudability make it a practical choice, especially for custom aluminum heat sinks in industrial or consumer electronics.

Feature | Aluminum (6063) | Copper (C11000) |

Thermal Conductivity | ~205 W/mK | ~390 W/mK |

Density | ~2.7 g/cm³ | ~8.96 g/cm³ |

Cost | Lower | Higher |

Weight | Lighter | Heavier |

Extrudability | Excellent | Poor |

Machinability | Good | Good |

Corrosion Resistance | Good (anodized) | Good |

Aluminum is lighter, easier to extrude, and significantly cheaper than copper. For applications like LED aluminum heat sink extrusion or automotive inverter heat sink, these advantages are critical for cost and design feasibility.

Versatility in Design: Extrusion enables complex fin geometries, including elliptical fins, flared fins, or integrated mounting features.

Excellent Strength-to-Weight Ratio: Essential for structural support and vibration resistance.

Corrosion Resistance: Enhanced with anodizing for durability and aesthetics.

Recyclability: Aluminum is fully recyclable, aligning with sustainability goals.

Cost-Effectiveness for Mass Production: Tooling costs are spread over high-volume production, reducing per-unit cost.

For extruded heat sinks, 6000 series alloys, especially 6061 and 6063, are preferred for their balance of thermal conductivity, mechanical strength, and extrudability.

6061: High strength, good machinability, thermal conductivity ~167 W/mK, ideal for high-stress applications like industrial inverters.

6063: Excellent extrudability, thermal conductivity ~201 W/mK, perfect for intricate fin designs, LED heat sinks, and custom profiles.

1050 & 3003: High conductivity but poor strength/extrudability; used mainly for simple cold plates.

You often balance conductivity and strength. Forextruded aluminum heat sinksused in 5G base station cooling, mechanical strength may be secondary to thermal performance. Conversely, automotive inverters demand higher structural integrity, favoring 6061.

The extrusion process transforms aluminum billets into complex heat sink profiles. Key steps include:

Billet Preparation: Heat aluminum to 400–500°C.

Die Loading: Preheated steel die shapes the profile.

Extrusion: Hydraulic press pushes aluminum through die.

Cooling: Air or water cools the extruded profile, setting temper (T5/T6).

Stretching/Straightening: Removes internal stresses, ensures dimensional accuracy.

Cutting: Profiles cut into heat sink blanks for machining/finishing.

Machining: Adds mounting holes, pockets, threads.

Anodizing: Improves corrosion resistance, electrical insulation, and aesthetics.

Chromate Conversion Coating: Optional corrosion protection.

Other Finishes: Powder coating or surface cleaning as needed.

Performance depends on fin geometry, airflow, thermal interface materials, and overall thermal resistance.

Height & Thickness: Optimize surface area vs. structural integrity.

Spacing & Aspect Ratio: Match convection type (natural vs. forced).

Shapes: Straight, elliptical, or flared fins improve airflow distribution.

Natural Convection: Passive, noiseless, requires wider spacing.

Forced Convection: Active cooling, allows higher fin density.

Airflow Management: Shrouds or ducting may optimize performance.

Pressure Drop: Balance fin density with fan capacity.

Base Thickness & Conductivity: Thicker base reduces hot spots.

Hybrid Solutions: Copper inserts or vapor chambers enhance heat spreading.

These heat sinks are versatile, appearing in consumer electronics, industrial automation, telecommunications, LED lighting, automotive electronics, and medical devices.

Industry | Example | Components |

Consumer Electronics | PCs, Gaming Consoles | CPU, GPU, Power Supplies |

Industrial Automation | Motor Drives, Controllers | IGBTs, MOSFETs |

Telecommunications | Base Stations, Servers | Power Amplifiers, Processors |

LED Lighting | High-Power LEDs | LED Arrays |

Automotive | EV Inverters, BMS | Power Electronics |

Medical | Diagnostic Equipment | Sensitive Electronics |

High Heat Flux: Combine aluminum with copper slug or vapor chamber.

Space-Constrained Designs: High-density, thin fins.

Liquid Cooling Integration: Custom extruded channels with cold plates.

Passive Cooling: Large, optimized fins with heat pipes for fanless designs.

Not necessarily. Efficient extruded aluminum heat sinks reduce total system cost by:

Allowing smaller, slower, cheaper fans

Reducing overall system weight and enclosure size

Extending component lifespan

Lowering power consumption

Simplifying assembly and reducing tooling costs

A system-level view shows that investing in a more efficient heat sink can save money and improve reliability.

TIMs bridge the gap between your component and heat sink, enhancing heat transfer. Common types:

Thermal Grease: Low resistance, high-performance CPUs/GPUs.

Thermal Pads: Easy, clean, electrically insulating.

Phase-Change Materials (PCMs): Pre-applied, conforming, stable long-term.

Proper application ensures microscopic air gaps are filled, maximizing efficiency.

Extruded aluminum heat sinks are essential for modern electronic designs, offering a balance of thermal performance, cost-effectiveness, and design flexibility. By optimizing material choice, fin design, airflow, and TIM selection, you can:

Maintain optimal operating temperatures

Extend component lifespan

Reduce total system costs

Achieve reliable, high-performance products

Whether you're designing for LED cooling solutions, automotive inverters, MOSFET heat sinks, or 5G base station cooling, leveraging custom extruded aluminum heat sinks ensures your thermal management is robust, efficient, and scalable.