Views: 22 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

Is your high-power electronics struggling to reach its full potential due to thermal limitations? Custom welding liquid cold plates are engineered solutions designed to precisely manage intense heat, directly enabling components to operate at their peak performance, ensuring stability, reliability, and extended operational life for even the most demanding applications.

In today's rapidly evolving technological landscape, the pursuit of higher power density in electronic components is relentless. From advanced processors in AI servers to robust power modules in electric vehicles, these innovations generate unprecedented heat loads. Generic cooling solutions often fall short, leading to thermal throttling, reduced efficiency, and premature component failure. This article explores how custom welding liquid cold plates, tailored to specific application needs, are the key to unlocking and sustaining peak performance in modern high-power electronics, offering a superior thermal management solution.

What is a Liquid Cold Plate and Why is it Essential for Peak Performance?

How Do Custom Liquid Cold Plates Work and What Materials Are Optimized?

What are the Key Manufacturing Processes for Custom Welding Liquid Cold Plates?

Why is Friction Stir Welding (FSW) Ideal for High-Performance Custom Cold Plates?

Where are Custom Welding Liquid Cold Plates Driving Peak Performance Across Industries?

How to Design and Choose the Right Custom Liquid Cold Plate for Your Needs?

High-power electronics such as CPUs, GPUs, power modules, and EV batteries generate extreme heat that traditional air cooling can no longer handle efficiently. A liquid cold plate is a precision-engineered heat exchanger that uses circulating coolant to absorb and transfer heat away from these components. By preventing overheating, liquid cold plates enable stable operation and unlock the system’s peak performance.

Compared to air cooling, a liquid cooling plate offers far greater thermal capacity, making it the preferred solution for today’s compact, high-power density applications in data centers, automotive electronics, and medical imaging systems.

At its core, a liquid cold plate functions as a thermal bridge between the hot electronic component and the cooling liquid. The design typically integrates microchannels, welded structures, or internal fins, which increase surface area and enhance heat transfer. Materials such as copper and aluminum are chosen for their high thermal conductivity, ensuring rapid heat absorption and transfer into the coolant.

Traditional air cooling is limited by the low thermal conductivity of air. As devices become smaller and more powerful, air cooling often leads to bulky designs, higher noise levels, and even thermal throttling. By contrast, custom liquid cold plates leverage the superior thermal properties of liquids—water, glycol-water, or dielectric fluids—providing compact, quiet, and highly efficient cooling.

For example, in high-performance computing (HPC) servers, a custom welded liquid cold plate can be mounted directly on CPUs or GPUs. The coolant absorbs the concentrated heat and carries it to a remote heat exchanger, ensuring processors consistently run at their maximum clock speeds without throttling. This closed-loop cooling system is also applied in electric vehicles and renewable energy systems, where maintaining efficiency under heavy load is critical.

Table 1.1: Comparison of Cooling Methods for Electronic Components

This table illustrates the fundamental differences between traditional air cooling and advanced liquid cold plate solutions, highlighting why liquid cold plates are essential for achieving peak performance in modern electronics.

Cooling Method | Heat Dissipation Capacity | Temperature Uniformity | Footprint | Impact on Peak Performance |

Air Cooling | Low to Moderate | Poor | Large | Limits sustained peak |

Liquid Cold Plate | High to Very High | Excellent | Compact | Enables sustained peak |

The escalating demands for thermal performance in modern electronics make custom liquid cold plates a critical solution. Are you curious about how liquid cold plates work and what materials are optimized to achieve superior cooling? This section will delve into the mechanics of how a precision liquid cooling plate efficiently transfers thermal energy from a heat source to a circulating fluid through conductive and convective heat transfer. We will also highlight the paramount role of material selection and optimization in ensuring maximum thermal efficiency and long-term reliability, ultimately helping your devices unlock peak performance.

Custom liquid cold plates function by efficiently absorbing and transferring heat. They draw heat from a mounted electronic component via a highly conductive, precisely designed base. This heat is then transferred to a circulating liquid coolant flowing through optimized internal channels. The heated coolant subsequently transports the thermal energy away for dissipation. These high-performance liquid cold plates are predominantly manufactured from materials boasting high thermal conductivity and excellent machinability, such as aluminum liquid cold plates and copper liquid cold plates. The specific material choice is optimized based on the application's thermal load, weight constraints, and desired performance, ensuring superior thermal management.

The operation of a custom liquid cold plate involves a continuous cycle of heat absorption, transport, and rejection, meticulously optimized for the specific heat source. It begins when a heat-generating component is mounted directly onto the cold plate's flat, highly conductive surface. Heat is then transferred from the component to the cold plate via conduction. The cold plate itself is typically made from materials like copper or aluminum, chosen for their excellent thermal conductivity, which allows for rapid heat absorption from the component, a critical step in maintaining peak performance.

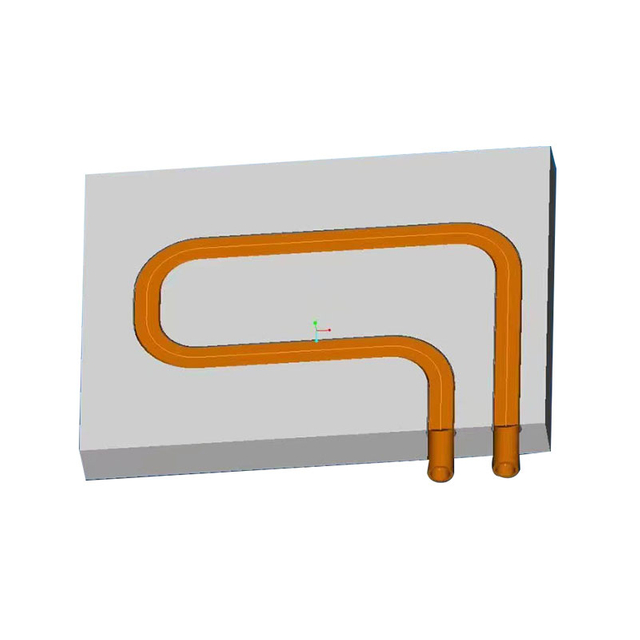

Once the heat enters the thermal cold plate, it is transferred to the liquid coolant flowing through the internal channels. This is where convection plays a crucial role. The coolant, often a mixture of water and glycol, absorbs the heat as it flows, increasing its temperature. The custom design of these internal channels – whether they are serpentine, parallel, or feature intricate fin structures – is meticulously optimized to maximize the surface area contact between the fluid and the cold plate material, thereby enhancing the convective heat transfer efficiency and directly contributing to the cold plate's ability to sustain peak component performance.

After absorbing the heat, the now-warmed coolant exits the cold plate heat exchanger and travels through a plumbing system to a heat rejection unit, such as a radiator with fans or a chiller. Here, the heat is transferred from the coolant to the ambient environment (or another cooling medium), and the cooled fluid is then pumped back to the cold plate, ready to absorb more heat. This continuous, optimized loop ensures that the component's temperature remains within its optimal operating range, allowing it to consistently deliver peak performance.

The choice of materials for custom liquid cold plates is paramount, primarily driven by their thermal conductivity, corrosion resistance, and compatibility with the chosen coolant, all balanced to achieve the desired performance and reliability.

Aluminum Alloys (e.g., 6061, 3003): Highly popular due to excellent thermal conductivity (160-200 W/m·K), lightweight nature, and cost-effectiveness. Easily machinable, allowing for complex custom channel designs. Widely used where weight or cost is a concern, such as in EV Battery Cold Plate cooling or industrial electronics, where custom aluminum cold plates can be optimized for specific power modules to ensure their peak performance.

Copper (e.g., C11000, C10200): Offers superior thermal conductivity (380-400 W/m·K), nearly twice that of aluminum, making it ideal for applications with extremely high heat fluxes where maximum performance is non-negotiable. Excellent corrosion resistance with water-based coolants. While denser and more expensive, custom copper cold plates are chosen for high-performance computing, laser systems, and power electronics cold plate applications where every degree of temperature reduction contributes to unlocking peak output.

Stainless Steel (e.g., 304, 316): While having significantly lower thermal conductivity (15-20 W/m·K), it is chosen for its exceptional corrosion resistance, particularly in harsh chemical environments or with aggressive coolants. Custom stainless steel cold plates are used in niche applications where chemical inertness and longevity are prioritized over pure thermal efficiency, ensuring long-term reliability even if peak thermal performance is slightly lower.

Evaluating a custom liquid cold plate's performance relies on understanding key metrics, which are carefully balanced during the design phase to achieve peak performance:

Thermal Resistance (Rth): The most critical metric, quantifying its ability to transfer heat (°C/W). A lower value indicates better cooling performance. In custom designs, engineers meticulously optimize internal fin designs and material interfaces to minimize this value, directly enabling components to run cooler and achieve peak output. This is crucial for any high heat flux cold plate.

Pressure Drop: The reduction in fluid pressure as it flows through the cold plate's internal channels. While a higher flow rate generally improves heat transfer, it also increases pressure drop. Custom designs balance these factors to ensure efficient heat removal without requiring an excessively powerful (and energy-consuming) pump, optimizing overall system performance.

Flow Rate: The volume of coolant passing through the cold plate per unit of time (LPM/GPM). Optimized flow rates are crucial for maximizing heat absorption and transport, directly impacting the cold plate's capacity to sustain peak thermal loads.

Table 2.1: Material Properties and Their Optimization for Custom Cold Plates

This table details common materials used in custom liquid cold plates, outlining their thermal conductivity, and how their properties are optimized to achieve specific performance goals in various applications.

Material | Thermal Conductivity (W/m·K) | Optimization for Peak Performance | Typical Custom Applications |

Aluminum Alloys | 160-200 | Lightweight, cost-effective for high-volume custom designs | EV Battery Cooling, Industrial Inverters (optimized for specific power modules) |

Copper | 380-400 | Max heat transfer for extreme heat fluxes, precise temp control | High-Power Lasers, Supercomputer CPUs (optimized for critical component stability) |

Stainless Steel | 15-20 | Corrosion resistance for harsh environments, long-term reliability | Chemical Processing, Medical Devices (where material inertness is key) |

Ever wondered how intricate, high-performance custom welding liquid cold plates are made? The manufacturing of these specialized liquid cooling plates involves diverse, precision-driven processes, from advanced machining to specialized welding and brazing techniques, each chosen and optimized based on the unique design complexity, material, and desired peak performance characteristics of the application.

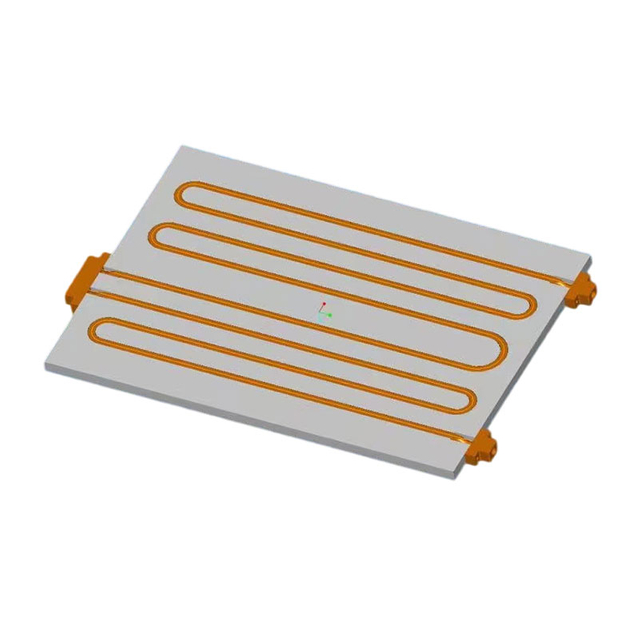

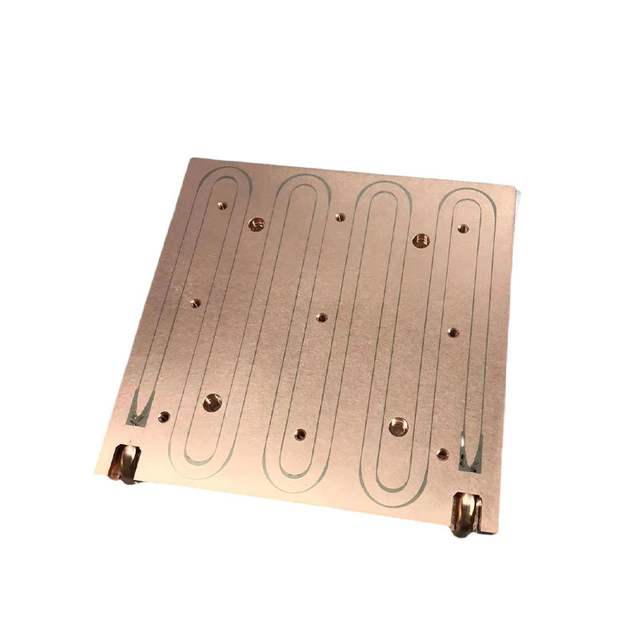

The main manufacturing processes for custom welding liquid cold plates include precision CNC machining, vacuum brazing, and advanced welding techniques like Friction Stir Welding (FSW), alongside deep processing and stamping. Each method is strategically selected and executed to enable the creation of highly customized solutions that meet stringent thermal performance requirements and ensure the long-term reliability necessary for unlocking peak component performance, making them a truly reliable liquid cold plate.

The fabrication of custom liquid cold plates is a sophisticated process that demands unparalleled precision and expertise. The choice of manufacturing method significantly impacts the cold plate's thermal performance, structural integrity, and cost, all of which are critical for achieving and sustaining peak performance.

Precision CNC Machining: This is a highly versatile method where a solid block of material (typically aluminum or copper) is precisely milled to create the intricate internal channels and external features. CNC machining offers exceptional design flexibility, allowing for complex internal geometries, microchannels, and integrated features tailored to specific thermal loads. It's ideal for prototypes, low-volume production, and custom designs requiring very tight tolerances to ensure optimal thermal contact and fluid flow, directly contributing to peak performance. This results in a highly effective CNC machined cold plate.

Example: A custom liquid cold plate for a high-end medical imaging device might be CNC machined from a solid aluminum block to achieve intricate serpentine channels and integrated mounting points, ensuring precise temperature control for sensitive electronics to operate at their diagnostic peak.

Vacuum Brazing: This process involves joining two or more metal pieces by melting a filler metal (with a lower melting point than the base materials) into the joint in a vacuum environment. Vacuum brazing is particularly effective for creating leak-tight bonds and is often used for joining complex fin structures to a base plate or sealing two halves of a cold plate. It creates strong, thermally conductive joints without significant distortion, which is crucial for maintaining the thermal path integrity necessary for peak performance. This produces a robust brazed liquid cold plate.

Example: A custom copper cold plate with internal copper fins might be vacuum brazed to create a high-performance solution for a supercomputer's CPU. The brazing ensures excellent thermal contact between the fins and the base, maximizing heat transfer and allowing the CPU to sustain its peak computational speed.

Friction Stir Welding (FSW): FSW is a solid-state joining process that uses a rotating tool to generate frictional heat, softening the material and allowing it to be stirred and forged together. It's particularly well-suited for joining aluminum alloys and is renowned for producing strong, defect-free, and low-distortion welds. FSW is increasingly popular for sealing two halves of a custom cold plate, creating robust and leak-proof fluid channels that are essential for long-term reliability and sustained peak performance in demanding environments. This is a key method for a welded liquid cold plate, specifically a Friction Stir Welded Cold Plate or FSW Liquid Cold Plate.

Example: A welded aluminum cold plate for an electric vehicle's power inverter might be manufactured by FSW, joining two machined halves. This method ensures a durable, leak-proof seal capable of withstanding vibrations and temperature cycles in an automotive environment, directly contributing to the inverter's ability to deliver peak power output reliably.

Deep Processing (Deep Drawn): This method involves forming a sheet metal blank into a desired shape using a punch and die. It's often used to create the top cover or a portion of the cold plate with integrated channels from a single piece of material. It's a cost-effective method for high-volume production of simpler custom cold plate designs, where the channels can be optimized for specific flow requirements.

Example: A custom liquid cold plate for a high-volume consumer electronics device might use a deep-drawn aluminum cover with pre-formed channels, which is then sealed to a base plate. This reduces manufacturing steps and material costs while still allowing for performance optimization through channel design.

Stamping: Similar to deep processing, stamping uses dies to cut and form sheet metal. It's often used for creating features like mounting holes, external fins, or simpler channel patterns in a cold plate. It's a very high-volume, low-cost manufacturing method that can be integrated into custom designs for specific external features or basic internal flow paths.

Example: A custom liquid cold plate for a telecommunications rectifier might have its external mounting features and simple internal flow paths created through stamping, followed by a sealing process, balancing cost-effectiveness with necessary thermal performance.

Table 3.1: Key Manufacturing Processes for Custom Cold Plates

This table summarizes the primary manufacturing techniques used for custom liquid cold plates, highlighting their unique characteristics and how they contribute to achieving specific design and performance goals.

Manufacturing Process | Description | Contribution to Customization & Peak Performance | Typical Custom Applications |

Precision CNC Machining | Material removal using cutting tools | High precision for complex, optimized geometries | Prototypes, High-end, unique thermal loads |

Vacuum Brazing | Joining with filler metal at high temp. | Strong, leak-tight bonds for high thermal contact | High-performance, multi-component assemblies |

Friction Stir Welding | Solid-state forging | Robust, low-distortion, leak-proof seals | EV, Power electronics (critical reliability) |

Deep Processing | Sheet metal forming | Cost-effective for volume, integrated channels | High-volume consumer, specific flow needs |

Stamping | Sheet metal cutting & forming | High volume for external features, basic channels | Mass-produced, cost-sensitive designs |

Heard about a welding technique that doesn't melt metal, and how it's revolutionizing the reliability and performance of custom cold plates? Friction Stir Welding (FSW) is a revolutionary solid-state joining process that creates incredibly strong and defect-free welds, making it an ideal method for manufacturing high-performance, leak-proof custom liquid cold plates, especially those made from aluminum, directly contributing to unlocking peak component performance.

FSW is ideal for high-performance custom liquid cold plates because its solid-state nature produces superior, defect-free, and highly ductile welds without melting the base material. This translates to exceptional leak integrity, minimal thermal distortion, and enhanced thermal performance, ensuring that custom cold plates are robust, reliable, and capable of sustaining the peak operational output of critical electronic components, making it the preferred method for a reliable liquid cold plate.

Unlike traditional fusion welding methods (like TIG or MIG welding) that rely on melting and re-solidifying the base material, FSW operates below the melting point. A specially designed, non-consumable rotating tool with a pin and shoulder is plunged into the joint line between two workpieces. As the tool rotates and traverses along the joint, the friction between the tool and the material generates localized heat, softening the metal to a plastic-like state. The rotating pin then stirs and forges the softened material from both sides of the joint, creating a solid-state bond. The shoulder of the tool applies downward pressure, containing the softened material and forging it into a dense, defect-free weld.

This process results in a fine-grained microstructure in the weld zone, often superior to the base material in terms of mechanical properties. Because no melting occurs, issues like solidification shrinkage, porosity, and hot cracking, common in fusion welding, are eliminated. This makes FSW particularly advantageous for materials like aluminum alloys, which are prone to these defects during conventional welding, ensuring the integrity needed for peak performance in a welded liquid cold plate.

The unique characteristics of FSW directly translate into tangible benefits for custom liquid cold plates, directly contributing to their ability to enable peak performance:

Superior Weld Strength and Ductility: FSW avoids the issues associated with melting and re-solidification, such as solidification cracking and porosity. The stirring action refines the grain structure in the weld zone, often making it stronger and more ductile than the parent material. This enhanced mechanical integrity means FSW custom cold plates can withstand higher internal pressures and external stresses (like vibration in automotive applications) without failure, crucial for sustained peak performance.

Example: In high-pressure industrial cooling systems, a custom FSW cold plate can reliably handle coolant pressures up to 100 PSI or more, ensuring the cooling system remains robust even under demanding operational loads.

Exceptional Leak Integrity: The dense, defect-free nature of FSW welds virtually eliminates porosity and micro-cracks, which are common sources of leaks in fusion welds. This makes FSW liquid cold plates inherently more reliable for fluid containment, a critical factor for any liquid cooling system where leaks could cause catastrophic damage to electronics and halt peak operation.

Example: For mission-critical aerospace or defense applications, where even a tiny leak could compromise system functionality, custom FSW cold plates are preferred. Rigorous helium leak testing can detect leaks as small as 10^-9 mbar·L/s, a standard easily met by FSW, providing high assurance for uninterrupted peak performance.

Minimal Distortion and Excellent Flatness: Since FSW operates below the melting point, the overall heat input to the workpiece is significantly lower than in fusion welding. This minimizes thermal distortion and residual stresses, resulting in a much flatter cold plate surface. Excellent flatness is crucial for optimal thermal contact with the heat-generating component, ensuring efficient heat transfer and directly enabling the component to operate at its peak. This is a key advantage of a welded liquid cold plate.

Example: When cooling a large, flat IGBT module, a highly flat FSW liquid cold plate ensures uniform contact across the entire module surface, preventing hot spots and maximizing heat dissipation, which is vital for the module's peak power output.

Enhanced Thermal Performance: The fine-grained microstructure of the FSW weld zone often exhibits improved thermal conductivity compared to coarser-grained fusion welds. Combined with the excellent flatness and leak integrity, this contributes to a lower overall thermal resistance for the custom cold plate, meaning more efficient heat removal from the component, directly supporting its ability to achieve and maintain peak performance.

Example: Custom FSW aluminum cold plates used in high-density data centers can demonstrate superior thermal performance, allowing CPUs and GPUs to run at higher clock speeds for longer durations without throttling, thus unlocking the peak computational power of the server.

Table 4.1: Advantages of FSW for High-Performance Cold Plates

This table highlights the key benefits of Friction Stir Welding (FSW) compared to traditional fusion welding, specifically in the context of manufacturing high-performance and reliable custom liquid cold plates.

FSW Advantage | Contribution to Peak Performance & Reliability | Comparison to Fusion Welding |

Superior Weld Strength | Withstands high pressures/vibrations, ensures longevity | Stronger, more ductile, no solidification defects |

Exceptional Leak Integrity | Prevents coolant leaks, critical for system uptime | Virtually defect-free, high reliability for fluid containment |

Minimal Distortion | Optimal thermal contact, no hot spots, precise fit | Flatter surfaces, reduces/eliminates post-machining |

Enhanced Thermal Performance | Lower thermal resistance, more efficient heat removal | Improved thermal path across the joint |

Wondering where custom welding liquid cold plates are making a tangible difference in unlocking peak performance? These specialized liquid cooling plates are indispensable across a wide array of industries, providing critical, tailored thermal management for high-power, high-density electronic systems where generic cooling methods simply cannot sustain peak operational output.

Custom welding liquid cold plates are widely applied in industries such as automotive (electric vehicles), medical equipment, data centers, telecommunications, industrial automation, and renewable energy. Their ability to efficiently dissipate high heat loads through tailored designs ensures optimal performance, reliability, and extended lifespan for critical electronic components, directly enabling these systems to achieve and maintain their peak operational capabilities as a premier custom thermal management solution.

The increasing power density of modern electronics, coupled with the demand for specific performance envelopes, has made custom liquid cold plates a go-to solution for thermal management in numerous sectors:

Automotive Industry (Electric Vehicles - EVs): EVs rely heavily on efficient, custom-designed thermal management for their battery packs, power inverters, and electric motors. Custom welding liquid cold plates are crucial for maintaining optimal operating temperatures, which directly impacts battery life, charging speed, motor efficiency, and overall vehicle performance and safety, ensuring the vehicle can deliver its peak power and range. This includes specialized EV Battery Cold Plate designs.

Example: In a high-performance EV, the battery pack incorporates a sophisticated, custom liquid cooling plate precisely designed to run between individual battery cells or modules. This ensures uniform temperature distribution across the entire pack, preventing thermal runaway and maximizing range and longevity, allowing the vehicle to consistently deliver peak acceleration and power.

Medical Equipment: High-precision medical devices, such as MRI machines, CT scanners, and high-power laser surgical tools, generate significant heat that must be precisely controlled to ensure diagnostic accuracy, patient safety, and equipment longevity. Custom liquid cold plates are engineered to meet these stringent requirements, enabling the equipment to operate at its diagnostic or therapeutic peak.

Example: An MRI machine's gradient coils and RF amplifiers require intense, custom-tailored cooling to maintain stable magnetic fields and signal integrity. Precision liquid cooling plates are integrated into these components, providing the necessary temperature stability for accurate imaging and ensuring the machine's peak diagnostic capability.

Data Centers and High-Performance Computing (HPC): As data centers become denser and processors more powerful, air cooling struggles to keep up. Custom liquid cold plates are increasingly used for direct-to-chip cooling of CPUs, GPUs, and memory modules, enabling higher rack densities and reducing energy consumption for cooling, directly unlocking the peak computational power of these systems. This often involves high heat flux cold plate designs.

Example: Leading data centers utilize custom welding liquid cold plates for their specialized AI accelerators (TPUs). These cold plates are precisely designed for the unique thermal profile of each chip, allowing for extreme computational power within a compact footprint while reducing overall data center energy usage and ensuring continuous peak AI processing.

Telecommunications: 5G infrastructure, base stations, and network equipment often operate in harsh outdoor environments and require robust, custom-engineered thermal management for their power amplifiers and processing units to maintain continuous peak network performance.

Example: A 5G base station's power amplifier module, which generates substantial heat, might be mounted on a ruggedized, custom liquid cold plate designed to withstand extreme outdoor temperatures and vibrations, ensuring continuous network operation and peak signal strength.

Industrial Automation and Power Electronics: Industrial drives, inverters, robotics, and welding equipment utilize high-power semiconductors (IGBTs, MOSFETs) that generate intense heat. Custom liquid cold plates are critical for maintaining their performance and preventing thermal failure, allowing these industrial systems to operate at their peak efficiency and output. This includes specialized power electronics cold plate solutions.

Example: A large industrial motor drive uses custom welding liquid cold plates to cool its IGBT modules, precisely designed for the specific power dissipation of the drive. This allows the drive to operate at high power levels continuously without overheating, which is essential for maintaining peak production rates in manufacturing processes.

Renewable Energy: Inverters for solar power systems and wind turbines, as well as battery energy storage systems, require efficient, customized cooling to maximize energy conversion efficiency and extend component life, ensuring the system delivers its peak energy output.

Example: A solar inverter's power conversion modules are often cooled by custom liquid cold plates, precisely engineered for the inverter's specific thermal profile. This ensures optimal efficiency and reliability, especially when operating in hot climates, maximizing energy harvest and system longevity.

Table 5.1: Industry Applications of Custom Welding Liquid Cold Plates

This table showcases various industries where custom welding liquid cold plates are deployed, highlighting the key components they cool and the primary benefits they provide in enabling peak performance for critical systems.

Industry | Key Components Cooled | How Custom Cold Plates Enable Peak Performance |

Automotive (EVs) | Batteries, Inverters, Motors | Tailored thermal control for max range, power, and safety |

Medical Equipment | MRI coils, Laser diodes | Precise temperature stability for diagnostic accuracy |

Data Centers / HPC | CPUs, GPUs, AI Accelerators | Enables higher density, sustained computational power |

Telecommunications | Power amplifiers, Base stations | Robust cooling for continuous, high-signal network operation |

Industrial Automation | IGBTs, Motor drives | Sustains high-power output, improves efficiency |

Renewable Energy | Inverters, Battery storage | Maximizes energy conversion, extends system lifespan |

Feeling overwhelmed by the options for high-performance cooling? Designing and choosing the right custom liquid cold plate involves a systematic approach, meticulously considering your specific thermal requirements, budget, space constraints, and long-term reliability needs to ensure optimal, peak performance for your unique application.

Selecting the ideal custom liquid cold plate requires a thorough assessment of your application's precise thermal load, desired operating temperature, and available space. Key steps include defining specific performance requirements, evaluating optimized material and manufacturing options (e.g., FSW for high reliability), considering coolant compatibility, and partnering with an experienced thermal solutions provider for expert custom design and optimization to unlock your system's peak performance with a reliable liquid cold plate.

The effectiveness of a custom liquid cold plate in enabling peak performance is a direct result of thoughtful engineering and precise design. Several interdependent parameters must be carefully considered and optimized:

Precise Thermal Load and Target Temperature: This is the foundational starting point. A detailed understanding of the maximum power dissipated by the component(s) (in Watts) and the exact desired operating temperature range (or maximum allowable temperature) dictates the required cooling capacity and influences the choice of materials and internal channel design for peak efficiency. This is crucial for any high heat flux cold plate.

Optimized Coolant Type and Properties: The choice of coolant (e.g., deionized water, glycol-water mixture, dielectric fluid) significantly impacts performance. Factors like specific heat capacity, thermal conductivity, viscosity, density, and corrosion properties must be carefully considered and optimized for the specific application. Viscosity affects pressure drop, while specific heat capacity determines how much heat the fluid can carry, directly influencing the cold plate's ability to sustain peak loads.

Tailored Flow Path Geometry (Channel Design): The internal design of the cold plate channels is crucial for maximizing heat transfer surface area and optimizing fluid flow. Custom designs can incorporate:

Serpentine Channels: Offer long flow paths, maximizing contact time with the heated surface, often chosen for concentrated heat sources.

Parallel Channels: Provide multiple shorter paths, leading to lower pressure drop, suitable for larger, more uniformly heated surfaces.

Microchannels: Extremely small channels (<1mm) that offer very high surface area-to-volume ratios, leading to exceptional heat transfer for ultra-high heat fluxes, though with higher pressure drop.

Optimized Fin Structures: Integrated fins (e.g., straight fins, pin fins, offset strip fins) within the channels further increase the wetted surface area, enhancing convective heat transfer and overall cooling power.

Design Trade-offs: Custom design involves balancing thermal performance (more surface area, higher flow velocity) with pressure drop (pump power, noise) and manufacturability to achieve the optimal solution for peak performance. CFD (Computational Fluid Dynamics) simulations are extensively used to optimize these complex designs for a precision liquid cooling plate.

Strategic Material Selection: As discussed previously, the choice of base plate material (welded aluminum cold plate, welded copper cold plate, stainless steel) is critical for thermal conductivity, weight, cost, and corrosion resistance. This selection is strategically made to match the specific thermal and environmental demands of the application, ensuring the cold plate can reliably enable peak performance.

Optimized Inlet/Outlet Port Location and Size: Proper placement and sizing of the ports ensure efficient fluid distribution and minimize flow restrictions. Incorrect placement can lead to uneven flow, creating "dead zones" with poor cooling, which would compromise peak performance. Custom designs carefully consider these aspects for seamless integration and optimal flow.

Choosing the perfect custom liquid cold plate is a collaborative process between the client and a specialized thermal solutions provider. Here's a structured approach:

Precisely Define Your Thermal Requirements: Provide comprehensive thermal specifications, including maximum power dissipation, desired component operating temperature range, ambient conditions, and any system-level constraints on pump power or flow rate. This detailed information is crucial for accurate thermal modeling and custom cold plate sizing.

Collaborate on Material and Manufacturing Options: Based on your defined requirements, discuss the optimal material (aluminum, copper, stainless steel) and the most suitable manufacturing process. For high-reliability, leak-proof custom aluminum cold plates, especially for demanding automotive or industrial applications, Friction Stir Welding (FSW) is often the superior choice due to its unparalleled integrity and contribution to sustained peak performance. This leads to a robust FSW liquid cold plate.

Ensure Coolant Compatibility and System Integration: Confirm that the chosen welding liquid cold plate material is fully compatible with your intended coolant to prevent galvanic corrosion or material degradation. Also, assess the physical space available, mounting requirements, and optimal port locations for seamless integration into your overall cooling loop.

Partner with an Experienced, Custom Thermal Solutions Provider: Look for a company with a proven track record in advanced thermal management and precision manufacturing, particularly with expertise in custom solutions and advanced techniques like FSW. A good provider will offer comprehensive design support, advanced thermal analysis (CFD), rapid prototyping, and rigorous testing capabilities (e.g., helium leak testing, burst pressure testing) to ensure your custom cold plate meets and exceeds peak performance expectations.

Kingka , with over 15 years of experience in custom liquid cold plates and precision CNC machining, is your trusted one-stop thermal management solution provider. Their highly technical design team offers free support, including thermal design and airflow simulation, to meticulously optimize a custom welding liquid cold plate solution tailored to your exact needs, ensuring your system achieves and maintains peak performance. With 24/7 production support and rapid global delivery, Kingka ensures timely project completion and superior quality, making them a leader in industrial liquid cold plate solutions.

Table 6.1: Key Design Considerations for Custom Liquid Cold Plates

This table outlines the essential parameters that must be considered during the design and selection process of a custom liquid cold plate, and their direct impact on the cold plate's performance and system integration.

Design Consideration | Key Factor | Impact on Peak Performance / System |

Thermal Load | Heat generated by component | Determines required cooling capacity for peak output |

Coolant Type | Fluid properties (viscosity, specific heat) | Affects heat transfer efficiency, pump load |

Channel Geometry | Internal flow path design (serpentine, micro) | Influences surface area, flow distribution, pressure |

Material Selection | Thermal conductivity, weight, cost | Dictates heat transfer efficiency and reliability |

Space Constraints | Available physical dimensions | Affects cold plate size and integration ease |

The relentless march of technological progress, characterized by ever-increasing power densities in electronic components, has rendered generic air cooling solutions largely inadequate for achieving and sustaining optimal output. Custom welding liquid cold plates, meticulously engineered and manufactured with advanced techniques like Friction Stir Welding (FSW), have emerged as indispensable thermal management solutions, offering superior heat dissipation, exceptional reliability, and precise design flexibility crucial for unlocking peak component performance. From the critical EV Battery Cold Plate cooling in high-performance electric vehicles to the demanding precision thermal control in medical devices and the high-density computational needs of data centers, custom liquid cold plates are the tailored workhorses ensuring optimal operation and extended lifespan for high-power electronics across diverse industries.

Choosing and designing the right custom liquid cold plate involves a nuanced understanding of precise thermal loads, optimized material properties, advanced manufacturing processes, and seamless system integration. By partnering with experienced thermal solution providers like Kingka, who possess deep expertise in custom liquid cold plate design, advanced manufacturing (including FSW), and rigorous testing, companies can confidently implement robust and efficient cooling strategies. As the demand for higher performance and smaller form factors continues to grow, the role of advanced, custom welding liquid cold plates will only become more critical in shaping the future of electronics and ensuring systems consistently deliver their full potential.