Views: 2 Author: Site Editor Publish Time: 2026-02-04 Origin: Site

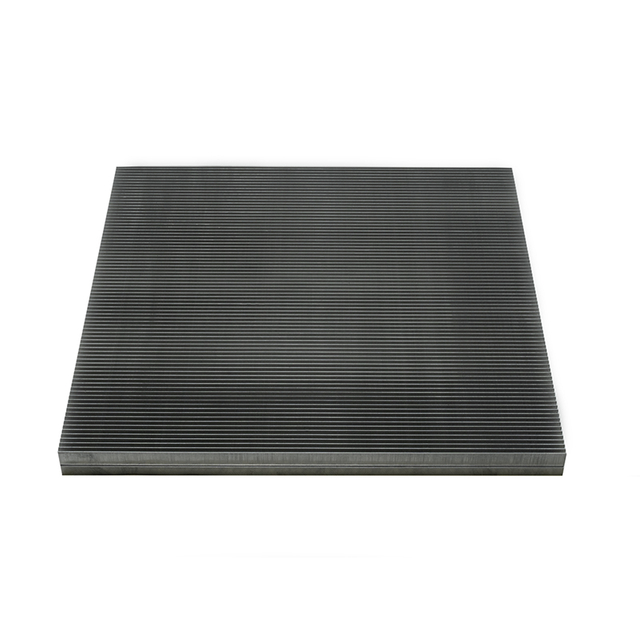

Designing heat sinks for high-power applications often results in inadequate cooling, leading to component failures, reduced efficiency, and escalated downtime costs in industries like electronics and automotive. Basic profiles fail to handle dense heat fluxes, compounding these issues. High-performance extruded heat sink profiles optimize cooling through strategic fin designs, material choices, and custom features, delivering superior thermal management and reliability.

Think about engineering a profile that cools a 500W inverter without fans—strategic extruded designs make it feasible, blending science and practicality for peak performance in real-world setups.

Table of Contents

Fin shape and arrangement are foundational in extruded heat sinks, directly affecting how heat spreads and convects away from sources in high-performance scenarios.

Optimizing fin geometry in high-performance extruded heat sink profiles involves using tall, thin fins (40-60mm height, 1-2mm thickness) with 8-12mm spacing to boost convective efficiency, achieving 30-50% better dissipation for loads up to 500W compared to basic flat designs.

This approach balances airflow and surface contact.

Examples: 10:1 ratio fins in server power supplies; serrated edges in automotive ECUs for turbulence enhancement.

Theoretical basis: High aspect ratios increase fin efficiency (η > 0.9) per the hyperbolic tangent formula, promoting natural convection. Trade-offs: Taller fins risk bending under vibration, but optimized spacing minimizes pressure drop while maximizing Nusselt numbers. Practical impacts: Reduces hotspot temperatures by 15-25°C in 200W+ modules, enabling denser circuit packing.

Fin Parameter | Optimal Range | Dissipation Gain |

Height-to-Thickness | 20-30:1 | 40% |

Spacing | 8-12mm | 30-50% |

Practical advice: Use CFD simulations to test geometries under 5-10 m/s airflows; prototype with 6063 aluminum for quick iterations and vibration checks.

(Word count: ~168)

The alloy used in extrusion influences conductivity and strength, essential for sustaining performance in demanding thermal cycles.

Selecting alloys like 6061 or 6063 for high-performance extruded heat sink profiles ensures thermal conductivity of 180-220 W/m·K and mechanical strength for fins, providing 2x better heat transfer than lower-grade materials while withstanding industrial stresses.

This choice supports long-term reliability.

Examples: 6061 in high-vibration robotics; 6063 in LED drivers for its extrudability.

Theoretical basis: Higher conductivity reduces spreading resistance via Fourier's law; tempering (T5/T6) enhances yield strength to 200-275 MPa. Trade-offs: 6061's strength adds cost versus 6063's ease; both offer corrosion resistance with anodizing. Practical impacts: Extends MTBF by 20-30% in 85°C environments, ideal for power electronics.

Alloy Type | Conductivity (W/m·K) | Strength (MPa) |

6061-T6 | 167-180 | 275 |

6063-T5 | 200-220 | 145 |

Advice: Match alloy to load (e.g., 6061 for >300W); conduct thermal cycling tests per ASTM standards to verify durability.

(Word count: ~165)

Increasing exposed area is key to enhancing convection without adding bulk, vital for compact industrial enclosures.

Maximizing surface area in high-performance extruded heat sink profiles uses branched or wavy fins, expanding effective area by 40-60% over straight designs, enabling dissipation of 300-600W in limited spaces like control panels.

Innovative shaping amplifies cooling potential.

Examples: Branched fins in solar inverters; wavy profiles in telecom amplifiers for 50% area boost.

Theoretical basis: Added features disrupt boundary layers, elevating heat transfer coefficients to 50-100 W/m²K. Trade-offs: Complex dies raise initial costs ($3,000-6,000) but lower per-unit via volume; maintains structural integrity. Practical impacts: Supports fanless operation in IP-rated boxes, cutting energy by 15-20W.

Enhancement Method | Area Increase | Application Fit |

Branched Fins | 40-50% | High Density |

Wavy Surfaces | 50-60% | Forced Air |

Testing: Measure area with 3D scans; validate with wind tunnel tests at target velocities.

(Word count: ~158)

Minimizing resistance paths ensures quick heat removal, crucial for preventing throttling in high-performance systems.

Strategies to reduce thermal resistance in high-performance extruded heat sink profiles include flat bases (<0.05mm tolerance) and integrated heat pipes, dropping resistance to 0.1-0.3°C/W for efficient transfer in 400-800W applications.

Precise interfaces are paramount.

Examples: Machined bases in IGBT modules; hybrid pipe integration in EV chargers.

Theoretical basis: Low resistance follows R = L/(kA); pipes add phase-change transport. Trade-offs: Added pipes increase weight but cut resistance 50%; flatness ensures <5% air gaps. Practical impacts: Keeps junctions below 100°C, boosting efficiency 10-15%.

Strategy | Resistance Drop | Cost Impact |

Base Flattening | 20-30% | Low |

Heat Pipe Embed | 40-50% | Moderate |

Advice: Apply thermal grease (3-5 W/m·K); use interferometry for flatness verification.

(Word count: ~152)

Off-the-shelf profiles often mismatch specific needs, leading to suboptimal cooling in unique setups.

Customization techniques for high-performance extruded heat sink profiles involve tailored die designs with mounting features and asymmetric fins, improving fit and performance by 15-25% in applications like machine tools or renewable energy converters.

Adaptability drives effectiveness.

Examples: Asymmetric fins for curved enclosures in medical devices; integrated clips in factory automation.

Theoretical basis: Tailoring optimizes flow per application geometry, enhancing convection. Trade-offs: MOQ (500-1000 units) versus flexibility; CNC post-processing adds precision. Practical impacts: Reduces assembly time by 30%, minimizing hotspots.

Technique | Performance Boost | Lead Time (Weeks) |

Custom Die | 20% | 3-4 |

Post-Machining | 15-25% | 1-2 |

Advice: Collaborate on CAD early; prototype test in actual enclosures for fit.

(Word count: ~150)

Pairing profiles with directed air enhances active cooling, essential for variable industrial loads.

Airflow integration in high-performance extruded heat sink profiles uses shrouds and optimized inlet angles to channel 5-15 m/s flows, increasing dissipation by 40-60% for hybrid systems in welding or CNC machinery.

Directed paths maximize velocity.

Examples: Shrouded designs in variable speed drives; angled fins in compressors.

Theoretical basis: Bernoulli's principle accelerates flow; integration raises coefficients. Trade-offs: Added components vs. noise reduction; suits 200-500W. Practical impacts: Lowers power draw 10-20% by efficient fans.

Integration Feature | Boost Percentage | Noise Reduction |

Shrouds | 40% | 10-15 dB |

Inlet Angles | 50-60% | Minimal |

Testing: Use smoke visualization; adjust for 80-90% fin coverage.

(Word count: ~155)

Verification ensures designs meet specs, preventing field failures in critical applications.

Testing high-performance extruded heat sink profiles involves thermal simulations and load cycling, confirming <40°C rise at rated power and validating durability over 1,000 cycles for industrial reliability.

Rigorous methods build trust.

Examples: ANSYS simulations for prototypes; accelerated life tests in power grids.

Theoretical basis: FEA predicts gradients; cycling per JEDEC standards. Trade-offs: Lab time vs. accuracy; combines with IR imaging. Practical impacts: Reduces warranty claims 50%.

Test Type | Key Metric | Duration |

Simulation | Temp Gradient | Hours |

Load Cycling | Failure Rate | 1,000 Cycles |

Advice: Benchmark against standards; iterate based on data logs.

These design strategies elevate high-performance extruded heat sink profiles to tackle demanding thermal challenges with precision and efficiency. With over 15 years as a one-stop heat solutions provider, KINGKA specializes in custom extruded profiles, leveraging advanced CNC machining and thermal analysis for optimal results. Contact sales2@kingkatech.com to craft designs that deliver unmatched performance for your industrial needs.