Views: 37 Author: Site Editor Publish Time: 2024-01-08 Origin: Site

In electronics, managing heat is crucial for ensuring the longevity and efficiency of devices. One of the critical components in this regard is the passive heat sink. Unlike its active counterparts that use fans or liquid cooling systems, a passive heat sink operates without any external power source, making it a vital solution in many applications. This article explores the world of custom passive heat sinks, their design, functionality, and why they are a preferred choice for many heat sink manufacturers.

A passive heat sink is a thermal management device that dissipates heat from electronic components without using external power sources like fans or pumps. These heat sinks rely on natural convection and radiation to cool components. The efficiency of a passive heat sink largely depends on its material, design, and environmental conditions.

While passive heat sinks operate without external power, active heat sinks use powered components like fans or liquid pumps to enhance heat dissipation. Choosing between a passive or active heat sink depends on various factors, including cooling requirements, space constraints, and noise considerations. Custom heat sink manufacturers often assess these factors when designing solutions for specific applications.

The design and choice of materials play a critical role in the effectiveness of passive heat sinks.

Aluminum: Popular due to its good thermal conductivity and lightweight characteristics. Custom heat sink manufacturers widely use it.

Copper: Offers better thermal conductivity than aluminum but is heavier and more expensive. It's often used in applications where high thermal conductivity is crucial.

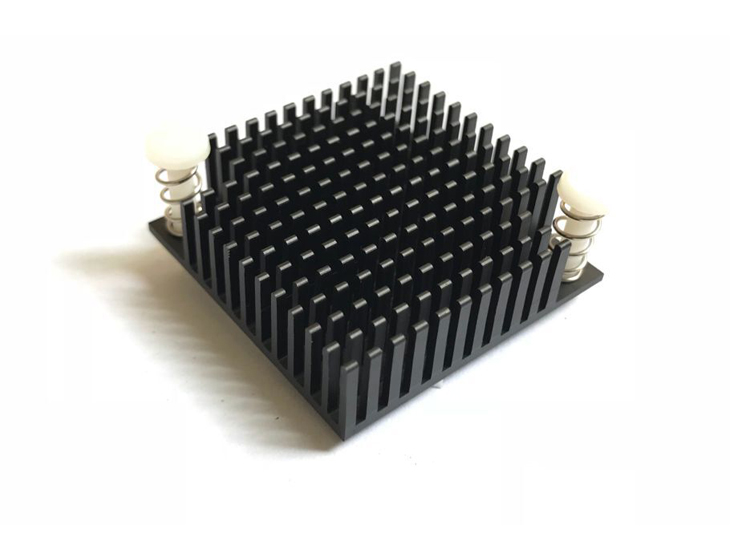

Surface Area: A larger surface area allows for more efficient heat dissipation. Designs with fins or ridges are standard in passive heat sink designs.

Fin Orientation and Density: The orientation and density of the fins can be optimized based on the airflow and cooling requirements.

Customization: Custom-designed heat sinks can cater to an application's specific thermal and spatial constraints, making them a versatile choice for challenging electronic designs.

The effectiveness of a passive heat sink hinges on its ability to transfer heat efficiently through two primary processes: conduction and convection.

Heat Transfer: Heat is conducted from the heat source (like a CPU) to the heat sink.

Material Efficiency: The material's thermal conductivity (typically aluminum or copper) plays a vital role in this process.

Natural Air Flow: Passive heat sinks rely on natural airflow for heat dissipation.

Design Impact: The design, especially the fin structure, impacts how effectively heat is dissipated into the surrounding air.

In passive heat sink design, these factors are meticulously considered to maximize heat dissipation without needing external power, making them ideal for custom heat sink solutions in various applications.

Passive heat sinks are widely used in various electronics due to their reliability and noise-free operation.

CPUs and GPUs: Essential for dissipating heat in processors and graphics cards.

Power Transistors: Common in high-power electronic circuits.

Noise-Sensitive Environments: Ideal for settings where noise reduction is crucial, like audio equipment or medical devices.

Reliability: With no moving parts, passive heat sinks are more reliable over time.

Custom Passive Heat Sink Manufacturers often tailor solutions for specialized equipment, ensuring optimal performance in specific environments.

Customization is critical in adapting passive heat sinks to specific needs and constraints.

Size and Shape: Customized to fit specific devices or enclosures.

Material Choice: Depending on thermal conductivity requirements and weight considerations.

Heat Sink Design: Tailored designs, like varying fin structures, to meet specific cooling needs.

Efficiency Optimization: Thermal analysis helps design heat sinks that are optimally efficient for the intended application.

Custom Solutions: Custom heat sink manufacturers use these analyses to create solutions that meet unique requirements, balancing performance with physical constraints.

Proper installation and maintenance are crucial for the optimal performance of passive heat sinks.

Secure Attachment: Ensuring the heat sink is properly attached to the component for effective heat transfer.

Thermal Interface Materials: Using quality thermal pastes or pads improves the thermal connection between the element and the heat sink.

Airflow Consideration: Positioning the heat sink to maximize natural airflow is especially important in passive heat sink designs.

Regular Cleaning: Dust accumulation can significantly reduce efficiency. Regular cleaning is essential.

Inspection of Thermal Interface: To maintain efficient heat transfer, periodically check and replace thermal interface materials.

Addressing frequently asked questions helps clarify doubts and assists in making informed decisions.

Customization Limits: What are the limitations in customizing passive heat sinks regarding size, shape, and material?

Selecting the Right Heat Sink: How do you choose the right passive heat sink for specific devices or applications?

Effectiveness in High Heat Scenarios: How effective are passive heat sinks in high-temperature situations compared to active solutions?

Passive heat sinks are a cornerstone in thermal management solutions for electronics. Their reliability and the potential for customization make them a go-to choice for various applications. Whether for standard electronics or specialized equipment, custom passive heat sink manufacturers ensure devices operate efficiently and safely. Understanding these components, installation, and maintenance is vital for anyone looking to utilize or customize passive heat sinks for their thermal management needs.