Views: 86 Author: Site Editor Publish Time: 2025-09-10 Origin: Site

Choosing between copper and nickel plating for your server CPU/GPU water block depends on balancing raw thermal performance, durability, and budget. While pure copper offers slightly superior thermal conductivity (400 W/m·K) for maximum heat transfer, nickel plating provides excellent corrosion resistance and easier maintenance, making it ideal for long-term reliability in enterprise liquid cooling systems, despite a minimal thermal trade-off.

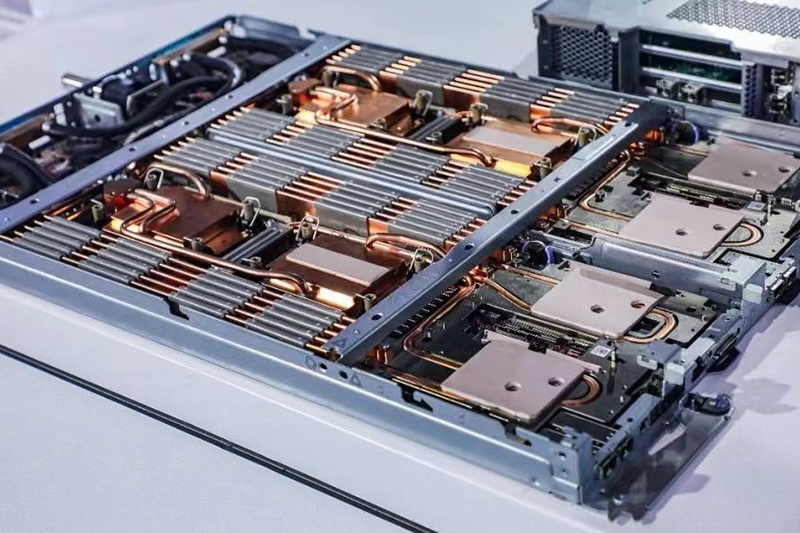

When it comes to high-performance server cooling, every detail matters. The material of your server CPU/GPU water block isn't just an aesthetic choice; it's a critical factor influencing thermal efficiency, long-term durability, and ultimately, the reliability of your entire liquid cooling system. As data centers push the boundaries of computational power, managing the intense heat from CPUs and GPUs becomes paramount. This often leads to a crucial decision: should you opt for the raw, unadulterated performance of pure copper, or the enhanced protection and sleek finish of nickel plating? Let's dive into the specifics to help you make an informed choice for your liquid cooling needs.

Which Application Scenarios Favor Copper or Nickel-Plated Copper?

What Material Options and Customization Does KingKa Tech Offer?

The choice of material for a server CPU/GPU water block is far more than a superficial detail; it's fundamental to the effectiveness and longevity of the entire liquid cooling system. This decision directly impacts how efficiently heat is transferred and how well the component withstands the rigors of continuous operation.

The role of materials in liquid cooling is critical, as the choice directly impacts a server CPU/GPU water block's thermal efficiency, durability, and cost. Materials like copper are selected for their high thermal conductivity, while coatings like nickel plating enhance corrosion resistance and longevity, making material selection a key factor in optimizing performance and reliability for demanding data center environments.

The primary function of a server CPU/GPU water block is to rapidly absorb heat from the processor and transfer it to a circulating liquid coolant. The material used for the water block's base and internal channels directly dictates how effectively this heat transfer occurs. A material with high thermal conductivity will pull heat away from the CPU or GPU more quickly, leading to lower operating temperatures.

Beyond thermal performance, the material also influences:

Corrosion Resistance: The internal environment of a liquid cooling loop can be corrosive, especially if the coolant is not perfectly maintained or if dissimilar metals are present. The water block material must resist degradation to prevent leaks and maintain performance.

Compatibility: The material must be compatible with the chosen coolant and other metals in the loop to avoid galvanic corrosion.

Manufacturing Precision: Some materials are easier to machine into the intricate microchannel designs required for optimal heat exchange.

For example, a custom cold plate designed for a 385W TDP processor needs a material that can handle that intense heat load efficiently. The material choice is the first step in achieving that goal.

Material Property | Impact on Waterblock Performance |

Thermal Conductivity | Direct impact on heat transfer speed and component temperature. |

Corrosion Resistance | Affects lifespan, reliability, and leak prevention. |

Mechanical Strength | Ensures structural integrity and mounting pressure. |

Machinability | Influences complexity of internal designs and manufacturing cost. |

The material choice creates a direct trade-off between three crucial factors:

Thermal Efficiency: Materials with higher thermal conductivity (like copper) will generally offer better heat transfer performance, leading to lower CPU/GPU temperatures. This is paramount for preventing thermal throttling in high-performance AI servers.

Durability: The material's resistance to corrosion, erosion, and mechanical stress determines the water block's lifespan and reliability. A durable material reduces the risk of leaks and premature failure, which is critical for 24/7 enterprise workloads.

Cost: Different materials and manufacturing processes come with varying price tags. Pure copper is often more affordable than specialized alloys or plated options, but the long-term costs of maintenance or replacement due to corrosion must also be considered.

For instance, a copper liquid cold plate might offer slightly better raw thermal performance at a lower initial cost, but if deployed in a harsh environment without proper coolant maintenance, its durability could be compromised. Conversely, a nickel-plated copper water block might have a slightly higher upfront cost but offer superior long-term reliability in such conditions.

This brings us to the central question: copper vs. nickel plating for your server CPU/GPU water block. Both have distinct advantages and disadvantages, and the "better" choice is highly dependent on your specific application, budget, and long-term goals.

Copper: The undisputed king of thermal conductivity among common metals used in cooling. It's excellent at moving heat but can be susceptible to oxidation and tarnishing.

Nickel Plating: Not a material itself, but a thin layer of nickel applied over a copper base. It aims to combine copper's thermal benefits with nickel's superior corrosion resistance and aesthetic appeal.

Understanding the nuances of each will empower you to make the optimal decision for your data center cooling strategy.

Copper has been the go-to material for high-performance heat sinks and water blocks for decades, and for good reason. Its inherent properties make it an excellent choice for direct-to-chip liquid cooling.

Copper waterblocks are characterized by their excellent thermal conductivity (up to 400 W/m·K), offering maximum heat transfer efficiency for server CPUs and GPUs. Their benefits include superior raw cooling performance and cost-effectiveness. However, copper is prone to oxidation, discoloration, and can react with certain coolants, requiring more diligent maintenance to prevent performance degradation and ensure longevity.

The standout property of copper is its exceptional thermal conductivity. Pure copper boasts a thermal conductivity of approximately 400 W/m·K, making it one of the best heat conductors among commercially available metals. This property is crucial for a server CPU/GPU water block because it directly dictates how quickly heat can be drawn away from the processor's surface.

In a custom cold plate designed for a high-TDP component (e.g., a 385W CPU or a 700W+ AI GPU), every millisecond of heat transfer efficiency counts. The rapid absorption and transfer of heat by copper ensures that the processor's temperature remains as low as possible, preventing thermal throttling and allowing it to operate at peak performance. This raw thermal performance is often the primary reason engineers choose copper for demanding thermal management applications.

Metal | Thermal Conductivity (W/m·K) |

Copper | ~400 |

Aluminum | ~237 |

Nickel | ~90 |

Stainless Steel | ~15 |

The benefits of choosing a pure copper waterblock are clear:

Maximum Heat Transfer: Due to its high thermal conductivity, copper provides the most efficient direct heat transfer from the CPU/GPU to the coolant. This can result in slightly lower operating temperatures compared to plated alternatives, which can be critical for pushing the absolute limits of performance in an AI server.

Cost-Effectiveness: Generally, pure copper water blocks are more cost-effective to manufacture than their nickel-plated counterparts. This can be a significant factor for large-scale deployments in data center cooling where budget constraints are tight.

Proven Performance: Copper has a long and established track record in liquid cooling and heat dissipation, making it a trusted choice for engineers.

For applications where every degree Celsius matters and budget is a primary concern, a high-quality copper liquid cold plate remains a top contender.

Despite its excellent thermal properties, pure copper does have some limitations that need to be considered:

Prone to Oxidation and Discoloration: When exposed to air and certain coolants, copper can oxidize and tarnish over time, developing a dull, brownish-green patina. While this surface oxidation doesn't significantly impact thermal performance initially, it can be aesthetically unappealing and, if left unchecked, could potentially lead to more severe corrosion.

Requires Maintenance: To maintain its pristine appearance and prevent potential long-term issues, pure copper water blocks may require more frequent cleaning and inspection. This can add to maintenance overheads in a large-scale data center cooling environment.

Reactivity with Coolants: Copper can react with certain coolant additives or if the coolant pH is not properly maintained, potentially leading to corrosion or the formation of deposits within the cooling loop. This necessitates careful coolant selection and regular monitoring.

Galvanic Corrosion Risk: If copper is directly coupled with more noble metals (like stainless steel or nickel) in the same cooling loop without proper inhibitors, galvanic corrosion can occur, where the copper acts as the anode and corrodes preferentially.

These limitations highlight why, despite its thermal prowess, pure copper isn't always the ideal choice for every server CPU/GPU water block application, especially in environments where long-term, low-maintenance reliability is paramount.

Nickel plating offers a clever solution to some of copper's inherent limitations, combining the best of both worlds. It's not a replacement for copper but an enhancement.

Nickel plating on copper waterblocks involves applying a thin layer of nickel over a copper base, providing superior corrosion resistance, an attractive aesthetic, and easier maintenance. While this nickel layer slightly reduces the overall thermal conductivity compared to pure copper, the trade-off is minimal in practice, making nickel-plated copper a popular choice for enhanced durability and long-term reliability in enterprise liquid cooling systems.

Nickel plating is an electroplating process where a thin layer of nickel is deposited onto the surface of a copper water block. This coating is typically very thin, often just a few micrometers thick, but it's enough to fundamentally change the surface properties of the copper. The underlying material remains copper, ensuring that the excellent thermal conductivity is largely preserved.

The purpose of this plating is not to enhance thermal performance (nickel itself has lower thermal conductivity than copper, around 90 W/m·K) but to provide a protective barrier. This barrier shields the reactive copper from direct exposure to air, moisture, and the coolant, addressing the limitations discussed earlier.

Material | Thermal Conductivity (W/m·K) | Primary Benefit |

Copper | ~400 | Excellent heat transfer |

Nickel | ~90 | Excellent corrosion resistance, hardness, aesthetics |

The advantages of nickel-plated copper for a server CPU/GPU water block are significant, particularly for enterprise and long-term deployments:

Superior Corrosion Resistance: This is the primary benefit. The nickel layer acts as a robust barrier, protecting the underlying copper from oxidation, tarnishing, and galvanic corrosion. This is crucial in complex liquid cooling loops where different metals might be present, or where coolant quality might fluctuate. It significantly extends the lifespan of the water block.

Enhanced Aesthetic Appeal: Nickel plating gives the water block a sleek, silver-like finish that is often preferred for its clean, professional look. This can be a factor in high-visibility server builds or for companies that prioritize a uniform aesthetic across their infrastructure.

Easier Maintenance: The nickel surface is much less prone to tarnish and discoloration, making it easier to clean and maintain. It resists staining and buildup, which can be a major advantage in large data center cooling operations where minimizing maintenance overhead is key.

Increased Hardness: Nickel plating can increase the surface hardness of the water block, making it more resistant to scratches and minor physical damage during installation or handling.

These benefits make nickel-plated copper a highly attractive option for server CPU/GPU water blocks where long-term reliability and reduced maintenance are paramount.

While nickel plating offers compelling advantages, it's important to acknowledge the trade-offs:

Slightly Lower Thermal Conductivity: As nickel has a lower thermal conductivity than copper, the thin layer of nickel technically adds a very small amount of thermal resistance. This means a nickel-plated copper water block will, in theory, have a marginally lower thermal performance than an identical pure copper block.

Higher Cost: The electroplating process adds an extra manufacturing step and material cost, making nickel-plated water blocks generally more expensive than their pure copper counterparts.

Potential for Peeling/Flaking: If the plating process is not done correctly, or if the water block is subjected to extreme conditions, there's a very small risk of the nickel layer peeling or flaking. However, with high-quality manufacturing processes (like those at KINGKA), this risk is virtually eliminated.

In practice, for most server CPU/GPU water block applications, the thermal performance difference between pure copper and nickel-plated copper is often negligible (typically less than 1-2°C difference), especially when considering the overall thermal resistance of the entire cooling loop. The benefits of corrosion resistance and durability often outweigh this minimal thermal trade-off.

When making a decision for your server CPU/GPU water block, a direct comparison of how copper and nickel plating stack up across key performance metrics is essential. This helps to quantify the trade-offs and align the choice with your specific priorities.

Comparing copper vs. nickel plating for server CPU/GPU water blocks reveals that pure copper offers marginally superior raw thermal efficiency due to its higher conductivity (400 W/m·K), though the difference is often negligible in practice. Nickel plating significantly enhances durability by providing corrosion resistance, requires less maintenance, but comes at a slightly higher cost, making it a trade-off between peak thermal performance and long-term reliability.

Pure Copper: Undeniably, pure copper has the highest thermal conductivity among the materials typically used for water blocks. This means it can absorb and transfer heat from the CPU/GPU to the coolant with maximum efficiency. For users pushing the absolute limits of overclocking or seeking every fraction of a degree lower temperature, pure copper might offer a theoretical edge.

Nickel-Plated Copper: The thin layer of nickel (thermal conductivity ~90 W/m·K) over the copper (thermal conductivity ~400 W/m·K) does introduce a very slight additional thermal resistance. However, because the layer is so thin (often 5-10 micrometers), its impact on the overall thermal performance of the water block is usually minimal. In most real-world server CPU/GPU water block applications, the difference in CPU/GPU temperatures between a high-quality pure copper block and a high-quality nickel-plated copper block is often within the margin of error or only 1-2°C. This difference is typically less significant than other factors in the cooling loop, such as coolant flow rate, radiator size, or ambient temperature.

Conclusion on Thermal Efficiency: While pure copper technically has a higher thermal conductivity, the practical difference in component temperatures for a well-designed server CPU/GPU water block is often negligible.

Feature | Pure Copper | Nickel-Plated Copper |

Thermal Conductivity | Excellent (~400 W/m·K) | Very Good (slight reduction due to nickel) |

Practical Temp Diff | Baseline | Often < 2°C higher than pure copper |

Pure Copper: As discussed, pure copper is susceptible to oxidation, tarnishing, and galvanic corrosion, especially in mixed-metal loops or with improperly maintained coolants. Over time, this can lead to material degradation, potential leaks, and reduced performance.

Nickel-Plated Copper: The nickel layer acts as a robust protective barrier. It is highly resistant to oxidation, tarnishing, and most forms of chemical corrosion. This significantly enhances the durability and extends the lifespan of the server CPU/GPU water block, making it a more reliable choice for long-term, 24/7 operation in demanding data center cooling environments. It also provides better protection against galvanic corrosion when paired with other metals in the loop.

Conclusion on Durability: Nickel plating offers a clear advantage in terms of corrosion resistance and overall durability, leading to a longer lifespan for the water block.

Pure Copper: Due to its tendency to oxidize and tarnish, pure copper water blocks may require more frequent cleaning to maintain their appearance and prevent potential buildup. This can add to maintenance overhead, particularly in large-scale deployments.

Nickel-Plated Copper: The smooth, non-reactive surface of nickel plating is much easier to clean and resists tarnish and discoloration. This translates to lower maintenance requirements and a consistently clean appearance, which is a significant benefit for busy AI data centers.

Conclusion on Maintenance: Nickel-plated water blocks are easier to maintain and require less frequent cleaning.

Pure Copper: Typically the more budget-friendly option, as it involves fewer manufacturing steps and materials.

Nickel-Plated Copper: The electroplating process adds an extra layer of manufacturing complexity and material cost, making these water blocks generally more expensive.

Conclusion on Cost: Pure copper usually has a lower upfront cost.

The "better" choice between copper and nickel-plated copper for your server CPU/GPU water block isn't universal. It depends heavily on your specific application, budget, and operational priorities.

Choosing between copper and nickel-plated copper for a server CPU/GPU water block depends on the application: pure copper is ideal for cost-sensitive projects or controlled environments with diligent maintenance, prioritizing raw thermal performance. Nickel-plated copper is superior for enterprise servers, high-humidity or corrosive environments, and premium builds where long-term reliability, minimal maintenance, and enhanced corrosion resistance are critical, balancing initial investment with extended lifespan.

Pure copper waterblocks are an excellent choice in specific scenarios:

Cost-Sensitive Projects: For projects where budget is a primary constraint, and every dollar counts, pure copper offers excellent thermal performance at a lower upfront cost. This might be relevant for smaller-scale deployments or proof-of-concept systems.

Environments with Controlled Maintenance: If your data center has a dedicated, meticulous maintenance team that can regularly inspect and clean cooling loops, and ensure strict coolant quality control, the limitations of copper can be effectively managed. This includes regular coolant changes and the use of appropriate anti-corrosion additives.

Absolute Peak Thermal Performance: For extreme overclocking or highly specialized AI servers where even a 1°C difference in component temperature could theoretically impact performance, pure copper might be preferred, assuming all other factors are perfectly controlled.

Closed-Loop Systems with Inert Coolants: In very specific, highly controlled closed-loop systems using inert coolants that do not react with copper, the corrosion risk is minimized.

Example: A research lab building a custom AI cluster on a tight grant budget, with in-house expertise for meticulous system maintenance, might opt for pure copper liquid cold plates to maximize performance per dollar.

Scenario | Why Copper is Suitable |

Budget-constrained | Lower initial cost. |

Dedicated Maintenance Team | Can manage oxidation/corrosion risks. |

Extreme Performance Demands | Marginally superior raw thermal conductivity. |

Controlled Coolant Environment | Reduced risk of reactivity. |

Nickel-plated copper is often the preferred choice for more demanding and long-term applications:

Enterprise Servers and Data Centers: For 24/7 enterprise workloads, reliability and minimal downtime are paramount. The superior corrosion resistance of nickel-plated copper significantly reduces the risk of leaks and component degradation, leading to higher uptime and lower maintenance costs over the long run.

High-Humidity or Corrosive Environments: In data centers located in humid climates, or where there's a risk of airborne contaminants, the protective nickel layer offers an invaluable barrier against external corrosion and tarnishing.

Mixed-Metal Cooling Loops: If your liquid cooling system contains a mix of different metals (e.g., aluminum radiators, brass fittings, stainless steel pumps), nickel-plated copper helps mitigate the risk of galvanic corrosion, which can occur when dissimilar metals are in contact with an electrolyte (the coolant).

Premium Performance Builds: For high-end AI servers or data center cooling solutions where aesthetics, ease of maintenance, and long-term stability are as important as performance, nickel-plated copper offers a compelling package.

Reduced Maintenance Overhead: For large-scale deployments, the reduced need for frequent cleaning and inspection of water blocks can lead to significant operational savings.

Example: A hyperscale AI data center deploying hundreds of GPU servers would almost certainly choose nickel-plated copper water blocks. The slightly higher upfront cost is easily justified by the drastically reduced risk of corrosion, lower maintenance requirements, and enhanced long-term reliability across thousands of components.

Ultimately, the decision boils down to balancing the initial investment against long-term reliability and maintenance costs.

Pure Copper: Lower initial cost, potentially higher long-term maintenance/risk if not properly managed.

Nickel-Plated Copper: Higher initial cost, significantly lower long-term maintenance/risk, leading to better overall Total Cost of Ownership (TCO) for critical applications.

For most enterprise and AI cluster applications, the enhanced durability and reduced maintenance offered by nickel-plated copper often make it the more cost-effective choice in the long run, despite the slightly higher upfront price.

At KINGKA, we understand that optimal thermal management requires flexibility and precision. That's why we offer a comprehensive range of material options and extensive customization capabilities for our server CPU/GPU water blocks.

KingKa Tech offers both pure copper and nickel-plated copper waterblocks, ensuring clients can choose based on their specific thermal, durability, and budget needs. Our high-precision CNC manufacturing guarantees optimal heat transfer, while our custom design capability allows for tailored solutions perfectly matched to diverse server architectures, high-TDP components, and demanding workloads, ensuring peak performance and reliability for any liquid cooling system.

Recognizing the distinct advantages of both materials, KINGKA provides server CPU/GPU water blocks in both pure copper and nickel-plated copper options. This allows our clients to make an informed decision based on their specific project requirements, budget constraints, and environmental considerations.

Pure Copper Options: For those prioritizing raw thermal performance and cost-effectiveness, especially in controlled environments, our high-purity copper liquid cold plates deliver exceptional heat transfer capabilities.

Nickel-Plated Copper Options: For clients demanding superior corrosion resistance, enhanced durability, and reduced maintenance for their enterprise servers or AI clusters, our nickel-plated copper water blocks provide a robust and reliable solution.

Our sales and technical teams are available to discuss the pros and cons of each material in the context of your specific application, helping you select the best fit for your data center cooling needs.

Regardless of the material chosen, the quality of manufacturing is paramount. KINGKA's commitment to precision ensures that every server CPU/GPU water block delivers optimal heat transfer:

Advanced CNC Machines: We are equipped with 35 sets of high-end CNC machines, enabling us to achieve incredibly tight tolerances and intricate internal microchannel designs. This precision is critical for maximizing the surface area in contact with the coolant and ensuring uniform flow.

Micron-Level Flatness: Our manufacturing processes ensure that the mating surface of the water block is exceptionally flat, minimizing gaps and maximizing contact with the processor's IHS. This is crucial for efficient heat absorption.

Robust Sealing: We utilize advanced sealing techniques like vacuum brazing for copper and FSW (Friction Stir Welding) for aluminum, ensuring leak-proof integrity for all our custom cold plates.

Strict Quality Control: Every water block undergoes at least four rigorous inspections, including dimensional checks with Automatic CMM and projectors, and comprehensive pressure testing to guarantee leak-free operation.

This meticulous manufacturing process ensures that whether you choose copper or nickel-plated copper, your KINGKA water block will perform reliably and efficiently, providing the thermal management your servers need.

One of KINGKA's core strengths is our ability to provide custom cold plates tailored to unique server architectures and demanding workloads. We understand that off-the-shelf solutions often fall short for specialized AI servers or high-density data center cooling.

Bespoke Designs: Our experienced R&D team, with over 25 years of expertise in mechanical machining and thermal fields, offers free technical design support. We can design water blocks to perfectly fit specific CPU sockets (e.g., Intel EGS platforms), GPU modules, or custom server chassis.

Thermal Optimization: We use thermal analysis software to simulate and optimize designs for your specific heat loads (e.g., 385W TDP) and coolant flow rates, ensuring maximum efficiency and minimal pressure drop.

Material Selection Guidance: Our team will guide you in selecting the most appropriate material (copper or nickel-plated copper) based on your performance targets, environmental conditions, and budget.

This comprehensive customization ensures that your server CPU/GPU water block solution is not just a component, but a perfectly integrated and optimized part of your liquid cooling infrastructure, delivering superior performance and long-term reliability.

The choice between copper and nickel plating for your server CPU/GPU water block is a nuanced one, with both materials offering distinct advantages. There's no single "better" option; rather, the optimal choice aligns with your specific priorities and operational context.

In conclusion, both copper and nickel-plated copper have valid applications for server CPU/GPU water blocks. Pure copper offers slightly superior raw thermal performance at a lower initial cost, making it suitable for budget-sensitive projects with controlled maintenance. Nickel-plated copper, while marginally more expensive, provides enhanced durability, superior corrosion resistance, and easier maintenance, making it ideal for enterprise servers, high-humidity environments, and applications prioritizing long-term reliability and reduced operational overhead.

For those seeking the absolute maximum in raw thermal conductivity and operating within a tight budget, with a commitment to diligent coolant maintenance, a pure copper waterblock can be an excellent choice. It delivers exceptional heat transfer for demanding CPUs and GPUs.

However, for the vast majority of enterprise data center cooling and AI cluster deployments, where long-term reliability, minimal maintenance, and robust protection against corrosion are paramount, nickel-plated copper often emerges as the more strategic investment. The slight theoretical thermal trade-off is typically outweighed by the significant benefits in durability and reduced operational risk.

Ultimately, the best recommendation is to evaluate your decision based on your specific budget, the environmental conditions of your data center, and your long-term goals for reliability and maintenance.

Don't leave your server's thermal management to chance. Consult with KingKa Tech's expert team today to discuss your specific requirements. We offer a full range of high-precision copper and nickel-plated copper CPU/GPU waterblock solutions, along with custom design capabilities, to ensure your liquid cooling system is perfectly tailored for optimal performance, energy efficiency, and long-term reliability.