Views: 3 Author: Site Editor Publish Time: 2025-10-27 Origin: Site

Liquid cold plate technology has fundamentally transformed thermal management across various sectors by enabling efficient, high-density heat removal from critical components. This innovation allows industries to push performance boundaries, enhance reliability, and achieve greater power efficiency in applications ranging from high-performance computing to electric vehicles, directly addressing the escalating thermal challenges of modern electronics.

Remember when computers used to be massive, slow, and prone to overheating? Or when electric vehicles had limited range due to battery heat? A lot has changed, and a silent hero behind much of this progress is liquid cold plate technology. As our devices get smaller, faster, and more powerful, they generate an incredible amount of heat. Air cooling, once sufficient, often can't keep up. That's where liquid cold plates step in, offering a far more efficient way to whisk away heat. This isn't just about keeping things cool; it's about unlocking new levels of performance, reliability, and efficiency across a range of industries. Let's dive into the top five sectors where liquid cold plates are truly making a revolutionary impact.

Before we explore its impact, let's clarify what liquid cold plate technology entails and why it's such a game-changer.

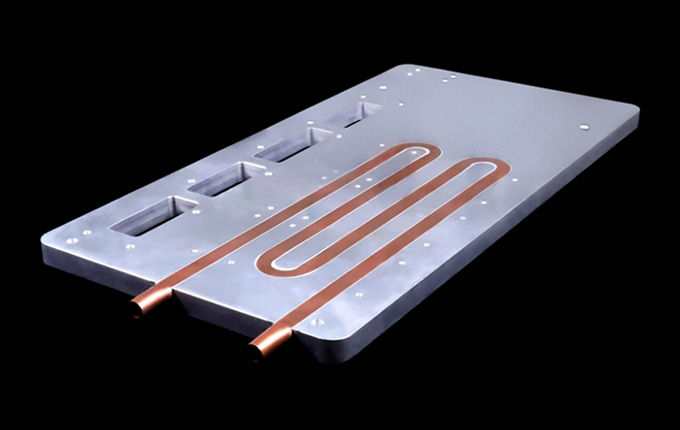

Liquid cold plate technology utilizes a sealed plate with internal channels through which a coolant fluid circulates, directly absorbing and transferring heat away from high-power components. This method is revolutionary because it offers significantly higher heat transfer coefficients than air cooling, enabling more compact designs, superior temperature uniformity, and enhanced reliability for devices generating substantial thermal loads.

At its core, a liquid cold plate is a highly efficient heat exchanger. Instead of relying on air to carry heat away, it uses a liquid – typically water, a water-glycol mixture, or a dielectric fluid. This liquid flows through precisely engineered channels within a metal plate (often copper or aluminum) that is in direct contact with the heat-generating component.

Here's why it's revolutionary:

Superior Thermal Conductivity of Liquids: Liquids have a much higher thermal conductivity and heat capacity than air. This means they can absorb and transport significantly more heat per unit volume, much faster. For example, water's specific heat capacity is roughly 4 times that of air.

Direct Contact for Efficient Transfer: The cold plate makes direct, intimate contact with the hot component, minimizing thermal resistance at the interface. This allows for rapid heat absorption.

Compactness and Density: Because liquids are so efficient, liquid cooling systems can be much smaller than air-cooling solutions for the same heat load. This is crucial for miniaturization and high-density packaging of electronics.

Temperature Uniformity: Liquid cold plates can maintain a more consistent temperature across the surface of a component, preventing hot spots that can degrade performance and reliability.

Noise Reduction: Liquid cooling systems can often operate more quietly than air-cooled systems, especially in data centers where numerous fans create significant noise.

Enabling Higher Performance: By effectively removing more heat, liquid cold plates allow components to operate at higher power levels and clock speeds without overheating, directly boosting performance.

Think of it this way: trying to cool a powerful processor with air is like trying to put out a bonfire with a hand fan. Using a liquid cold plate is like using a fire hose – it's far more effective and targeted. This fundamental shift in thermal management has opened doors for innovation across countless industries.

The relentless demand for faster processing in HPC and data centers has made liquid cold plate technology indispensable.

Liquid cold plate technology is revolutionizing High-Performance Computing (HPC) and data centers by directly cooling CPUs, GPUs, and memory modules, enabling significantly higher power densities and reducing energy consumption. This allows for more compact server racks, prevents thermal throttling, and ensures stable operation of critical infrastructure, directly addressing the escalating heat loads of modern processors and AI accelerators.

In the world of supercomputers, artificial intelligence, and massive data processing, every watt of power translates into heat. Traditional air cooling struggles to keep up with the thermal design power (TDP) of modern CPUs and GPUs, which can easily exceed 300-500W per chip. This is where liquid cold plates become not just an advantage, but a necessity.

Challenge: Modern server processors (e.g., Intel Xeon, AMD EPYC) and especially AI accelerators (e.g., NVIDIA H100, AMD Instinct MI300X) generate immense localized heat. Air can't efficiently remove this heat from the small surface area of the chip.

Solution: Liquid cold plates are mounted directly onto these chips. A coolant (often deionized water or a dielectric fluid) flows through the cold plate, absorbing heat directly from the silicon. This heat is then transported to a larger heat exchanger (like a radiator) and ultimately rejected from the data center.

Impact:

Higher Power Density: Allows data centers to pack more computing power into the same physical footprint, maximizing real estate.

Elimination of Thermal Throttling: Ensures processors can run at their maximum clock speeds continuously, without performance degradation due to overheating.

Reduced Energy Consumption: While liquid cooling systems have pumps, they often reduce the overall energy consumption of a data center by being more efficient than the massive fans required for air cooling, and by allowing for higher ambient temperatures in the facility.

Enhanced Reliability: Stable operating temperatures extend the lifespan of expensive components.

Rack-Level Liquid Cooling: Beyond individual chips, entire server racks are being designed with integrated liquid cooling loops. Cold plates cool components, and the warm liquid flows to a manifold at the back of the rack, then to a central cooling unit.

Immersion Cooling: In some advanced data centers, entire servers are submerged in a non-conductive dielectric fluid. This fluid directly cools all components, and then circulates through a heat exchanger. While not strictly cold plates, it's the ultimate extension of liquid cooling principles.

Examples: Google's custom liquid-cooled Tensor Processing Units (TPUs), NVIDIA's HGX platforms, and various enterprise liquid-cooled server solutions from companies like HPE and Dell.

The revolution in HPC and data centers driven by liquid cold plate technology is enabling the next generation of AI, scientific research, and cloud computing.

The rapid growth of the EV market is intrinsically linked to the advancements in liquid cold plate technology for battery and power electronics cooling.

Liquid cold plate technology is revolutionizing Electric Vehicles (EVs) by providing precise thermal management for high-voltage battery packs and power electronics, which are critical for performance, range, and safety. By efficiently removing heat during charging and discharge, cold plates prevent thermal runaway, extend battery lifespan, and optimize the operating temperature of inverters and motors, directly enabling the widespread adoption and advancement of EV technology.

Electric vehicles rely on powerful battery packs and sophisticated power electronics (inverters, motors, onboard chargers) that generate significant heat. Managing this heat is paramount for the EV's performance, safety, and longevity. Air cooling is simply inadequate for these concentrated heat sources.

Challenge: Lithium-ion batteries perform optimally within a narrow temperature range (typically 20-40°C). Too hot, and they degrade rapidly, risk thermal runaway (fire), and lose capacity. Too cold, and their performance and charging speed are severely limited. Fast charging generates immense heat.

Solution: Liquid cold plates are integrated directly into the battery pack, often positioned between individual battery cells or modules. A coolant (typically a water-glycol mixture) circulates through these plates, absorbing heat from the cells during discharge and fast charging, and sometimes warming them in cold weather.

Impact:

Extended Battery Lifespan: Maintaining optimal temperatures significantly prolongs the life of the expensive battery pack.

Enhanced Safety: Prevents thermal runaway events by quickly dissipating heat.

Improved Performance and Range: Allows batteries to operate efficiently, delivering consistent power and maximizing range.

Faster Charging: Enables higher charging rates by effectively managing the heat generated during rapid energy transfer.

Examples: Tesla's serpentine liquid cooling system, which weaves through the battery pack, and similar designs in vehicles from Porsche (Taycan), Audi (e-tron), and General Motors (Ultium platform).

Challenge: The inverter (which converts DC battery power to AC for the motor) and the electric motor itself generate substantial heat, especially under heavy acceleration or regenerative braking.

Solution: Dedicated liquid cold plates are used to cool the IGBTs (Insulated Gate Bipolar Transistors) within the inverter and the stator windings of the electric motor.

Impact:

Increased Efficiency: Allows power electronics to operate at peak efficiency without overheating.

Higher Power Output: Enables more powerful motors and faster acceleration.

Reliability: Prevents premature failure of critical power components.

The revolution in EVs is powered by efficient thermal management, with liquid cold plate technology at its core, ensuring safe, high-performance, and long-lasting electric transportation.

In the demanding world of industrial power and control, liquid cold plate technology is crucial for reliability and efficiency.

Liquid cold plate technology is revolutionizing power electronics and industrial automation by providing robust and efficient cooling for high-power components like IGBTs, MOSFETs, and rectifiers. This enables higher power density in industrial drives, inverters, and renewable energy converters, enhancing system reliability, extending component lifespan, and allowing for more compact and sealed enclosures in harsh industrial environments.

Industrial environments are often harsh, with dust, vibration, and wide temperature swings. Power electronics, such as those found in motor drives, inverters, and power supplies, generate significant heat that must be managed effectively to ensure continuous operation and prevent costly downtime.

Challenge: Components like IGBT modules (Insulated Gate Bipolar Transistors) and high-power MOSFETs, used in variable frequency drives (VFDs), uninterruptible power supplies (UPS), and industrial inverters, can dissipate hundreds or even thousands of watts of heat from a very small area. Air cooling is often insufficient and can lead to bulky, open enclosures susceptible to contamination.

Solution: Direct-to-component liquid cold plates are the standard. These are often custom-designed to fit the specific footprint of the semiconductor module, ensuring maximum thermal contact. The coolant circulates through the cold plate, efficiently drawing heat away.

Impact:

Increased Power Density: Allows for more powerful and compact industrial equipment.

Enhanced Reliability and Lifespan: Stable operating temperatures prevent thermal stress and extend the life of expensive power modules, reducing maintenance costs.

Operation in Harsh Environments: Liquid-cooled systems can be sealed, protecting sensitive electronics from dust, moisture, and corrosive agents, which is critical in factories, mines, or outdoor installations.

Improved Efficiency: Keeping semiconductors cool reduces their electrical resistance, leading to less energy loss.

Challenge: High-performance industrial robots and automated machinery often contain powerful servo drives and control systems that generate heat, especially during continuous operation.

Solution: Compact liquid cold plates are integrated into the control cabinets or directly onto the drives, ensuring consistent performance.

Impact:

Continuous Operation: Prevents overheating that could lead to robot shutdowns or performance degradation.

Precision Control: Stable temperatures contribute to more accurate and reliable robotic movements.

The revolution in power electronics and industrial automation, driven by liquid cold plate technology, is enabling more robust, efficient, and reliable machinery that can operate in increasingly demanding conditions.

Precision and reliability are paramount in medical and scientific fields, where liquid cold plate technology ensures optimal performance.

Liquid cold plate technology is revolutionizing medical imaging and laser systems by providing precise and stable thermal management for high-power components, ensuring consistent image quality, accurate laser output, and extended equipment lifespan. This critical cooling prevents thermal drift in MRI and CT scanners, maintains wavelength stability in high-power lasers, and enables reliable operation of diagnostic and therapeutic devices, directly impacting patient care and scientific research.

Medical and scientific equipment often involves high-power components that require extremely stable and precise temperature control. Any thermal instability can lead to inaccurate results, compromised image quality, or even equipment failure.

Challenge: Devices like MRI (Magnetic Resonance Imaging) scanners, CT (Computed Tomography) scanners, and X-ray machines contain powerful RF amplifiers, detectors, and high-voltage power supplies that generate significant heat. Maintaining precise temperature stability is crucial for image quality and diagnostic accuracy.

Solution: Custom-designed liquid cold plates are used to cool these critical components. For example, in MRI systems, cold plates might cool the gradient amplifiers, which are responsible for rapidly changing magnetic fields and generate substantial heat.

Impact:

Consistent Image Quality: Prevents thermal drift that could distort images or reduce resolution, ensuring reliable diagnoses.

Extended Equipment Lifespan: Protects expensive, sensitive components from thermal degradation.

Reduced Downtime: Reliable cooling minimizes failures, ensuring equipment is available for patient care.

Compact Design: Allows for more streamlined and space-efficient medical devices.

Challenge: Industrial lasers (for cutting, welding, marking) and medical lasers (for surgery, dermatology) generate intense heat at the laser diode or gain medium. Even slight temperature fluctuations can cause wavelength shifts, power instability, and reduced beam quality.

Solution: Highly efficient liquid cold plates are used to precisely cool the laser diodes, optics, and power supply components. The coolant temperature is often tightly controlled to maintain the laser's optimal operating point.

Impact:

Stable Laser Output: Ensures consistent power and wavelength, critical for precision applications.

Enhanced Beam Quality: Prevents thermal lensing effects that can degrade the laser beam.

Increased Lifespan of Laser Diodes: Diodes are highly sensitive to temperature; precise cooling extends their operational life.

Higher Power Levels: Enables the development of more powerful and versatile laser systems.

The revolution in medical imaging and laser systems, powered by liquid cold plate technology, is directly contributing to advancements in diagnostics, treatment, and scientific discovery.

The drive towards sustainable energy relies heavily on efficient thermal management, making liquid cold plate technology vital for renewable energy systems.

Liquid cold plate technology is revolutionizing renewable energy systems by efficiently cooling the power conversion electronics in solar inverters, wind turbine converters, and energy storage systems. This enables higher power output, enhances reliability, and extends the lifespan of critical components, directly supporting the efficient integration and stable operation of renewable energy sources into the grid, even under demanding environmental conditions.

Renewable energy sources like solar and wind power rely on sophisticated power electronics to convert the generated energy into a usable form for the grid or for storage. These power conversion systems, much like those in EVs and industrial automation, generate significant heat that must be managed effectively for optimal performance and longevity.

Challenge: Solar inverters convert the DC power from solar panels into AC power for homes and the grid. They contain high-power IGBTs and MOSFETs that generate substantial heat, especially in hot outdoor environments. Overheating reduces efficiency and shortens the inverter's lifespan.

Solution: Liquid cold plates are increasingly used to cool the semiconductor modules within high-power string inverters and central inverters. The sealed nature of liquid cooling also protects components from dust and moisture in outdoor installations.

Impact:

Increased Power Output and Efficiency: Allows inverters to operate at peak performance, maximizing energy harvest from solar panels.

Enhanced Reliability: Extends the lifespan of expensive inverter components, reducing maintenance and replacement costs.

Operation in Harsh Climates: Enables inverters to function reliably in extreme temperatures and dusty conditions.

Compact Design: Allows for smaller, more aesthetically pleasing inverter units.

Challenge: Wind turbines use power converters to manage the variable output from the generator and convert it into stable grid-compatible AC power. These converters are located within the nacelle (the housing at the top of the tower), which can experience significant temperature swings and vibrations.

Solution: Robust liquid cold plates are used to cool the power semiconductor modules within these converters, ensuring stable operation under dynamic conditions.

Impact:

Reliable Grid Integration: Ensures consistent power delivery from wind farms.

Extended Component Lifespan: Critical for components in remote and hard-to-access locations.

High Efficiency: Maximizes the energy captured from the wind.

Challenge: Large-scale battery energy storage systems, used to balance the grid or store renewable energy, face similar thermal management challenges to EV battery packs. Charging and discharging cycles generate heat that can degrade battery performance and safety.

Solution: Liquid cold plates are integrated into battery modules within ESS containers to maintain optimal operating temperatures for the battery cells.

Impact:

Optimized Battery Performance: Ensures efficient energy storage and retrieval.

Enhanced Safety: Mitigates the risk of thermal runaway in large battery arrays.

Extended System Lifespan: Protects the significant investment in battery technology.

The revolution in renewable energy, driven by liquid cold plate technology, is making sustainable power generation and storage more efficient, reliable, and economically viable.

The journey through these five industries clearly demonstrates that liquid cold plate technology is far more than just a cooling method; it's an enabler of innovation.

In conclusion, liquid cold plate technology has profoundly revolutionized industries by providing unparalleled thermal management for high-power density applications. From enabling the performance of HPC and EVs to ensuring the reliability of industrial automation, medical systems, and renewable energy, cold plates are critical for preventing overheating, extending component lifespan, and pushing the boundaries of technological advancement. As power densities continue to rise across all sectors, liquid cooling will remain an indispensable solution, driving future innovation and efficiency.

From the blazing-fast processors in data centers to the powerful battery packs in electric vehicles, the common thread is the need to manage ever-increasing heat loads in ever-decreasing spaces. Air cooling, with its inherent limitations, is increasingly being replaced or augmented by the superior efficiency of liquid cold plates.

This technology allows engineers to design systems that are:

More Powerful: Components can run at higher clock speeds and power outputs.

More Reliable: Stable temperatures prevent thermal stress and extend the lifespan of expensive electronics.

More Compact: Higher heat removal efficiency means smaller cooling solutions, leading to smaller, sleeker products.

More Efficient: Reduced energy consumption for cooling and improved electrical efficiency of components.

As we continue to push the boundaries of technology – whether it's developing more powerful AI, longer-range EVs, smarter factories, or advanced medical devices – the thermal challenges will only intensify. Liquid cold plate technology stands ready to meet these challenges, ensuring that the innovations of tomorrow can operate reliably and efficiently. It's clear: the future of high-performance technology is, quite literally, liquid-cooled.

Facing a critical thermal challenge in your industry? Don't compromise on performance or reliability. KingKa Tech is your trusted one-stop thermal solution provider, specializing in high-quality customized liquid cold plates, heat sinks, and precision CNC machining services. With over 15 years of experience and a dedicated R&D team, we offer free technical design support, thermal analysis, and airflow simulations to help you design and implement the perfect liquid cold plate solution for your unique needs. Contact us today to unlock new levels of performance and efficiency for your high-power applications!